High-wavelength antimonide semiconductor laser structure

A laser and antimonide technology, applied in semiconductor lasers, lasers, laser parts, etc., to improve structural efficiency, reduce optical mode loss, and improve performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

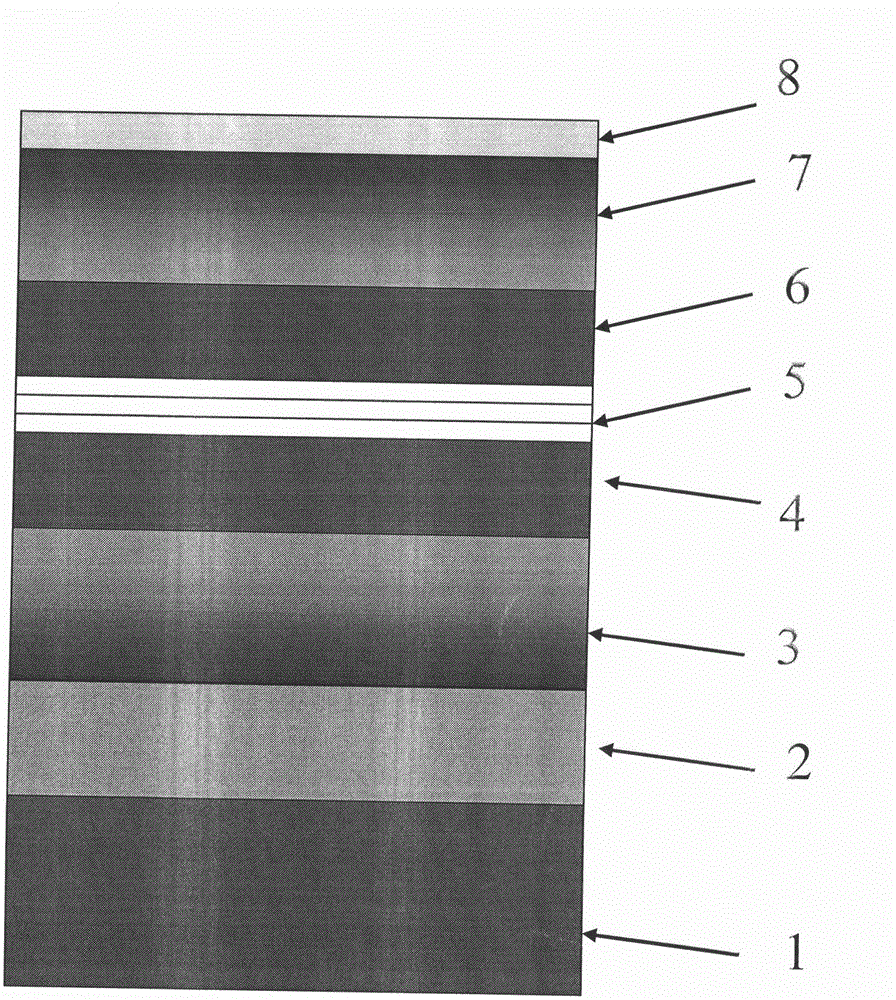

[0008] like figure 1 As shown, a long-wavelength antimonide semiconductor laser structure includes:

[0009] The substrate 1 has a (100) orientation and a Te doping concentration of 1 to 2×10 18 cm -3 GaSb crystal material.

[0010] GaSb buffer layer 2, growth temperature 560°C, Te doping concentration 2×10 18 cm -3 , thickness 1 μm.

[0011] Al x Ga 1-x Sb lower confinement layer 3, grown at a temperature range of 540-560°C, doped with Te at a concentration of 1×10 19 cm -3 -3×10 18 cm -3 , growing 1.2 μm. Using variable Al composition and segmented-gradient doping design and growth, combined with figure 1 It shows that from the direction of layer 3 to layer 4, the Al composition x changes from 0.9 to 0.75 at the first growth thickness of 0.7 μm. The doping concentration is changed from 1×10 19 cm -3 Change to 5×10 18 cm -3 . For the thickness of 0.5 μm grown next, the Al composition x changes from 0.75 to 0.45, and the doping concentration changes from 5×10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com