Adsorption purification unit and adsorption recycling device for recycling organic solvent from waste gas

A purification unit and organic solvent technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problem that electrothermal regeneration technology stays in the laboratory research stage, and the self-compacting problem of granular activated carbon bed is difficult to solve. Realize engineering application and other problems, and achieve the effect of complete removal, less overall equipment investment and long replacement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

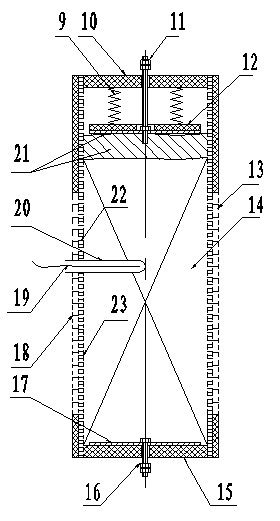

[0037] The adsorption and purification unit for recovering organic solvents from waste gas in this embodiment is a box-type hexahedral structure, such as figure 1 As shown, including: upper bottom surface 10, lower bottom surface 15, left side 18, right side 13 and front and rear sides (not shown) of the shell, activated carbon bed 14, upper electrode 21, lower electrode 17, carbon steel spring 9 , the middle partition 12 and the electric coupler 19, wherein: the right side 13 and the left side 18 are made of phenolic resin grid plate, lined with polyimide sieve plate 22 and glass fiber gauze 23, in order to facilitate the removal of organic waste gas After entering and purifying, clean air is discharged, and the activated carbon bed 14 filled inside is columnar granular activated carbon with a diameter of Ф3mm.

[0038] The upper and lower ends of the activated carbon bed 14 are provided with an upper electrode 21 and a lower electrode 17. The upper electrode 21 is made of a ...

Embodiment 2

[0045] The adsorption and purification unit for recovering organic solvents from waste gas in this embodiment is a cylindrical structure, such as Figure 4 As shown, it includes: the upper bottom surface 10, the lower bottom surface 15, the outer cylindrical surface 24, the inner cylindrical surface 25 of the cylindrical shell, the activated carbon bed 14, the upper electrode 21, the lower electrode 17, the carbon steel spring 9, the middle partition 12 and Electric coupler 19, wherein: the outer cylindrical surface 24 and the inner cylindrical surface 25 are the air inlet and outlet surfaces respectively, the upper end of the inner cylinder of the middle hole is open, and the lower end is closed, so that polluted air can only enter the adsorption purification unit from the outer cylindrical surface 24, After being purified by the activated carbon bed 14, it is discharged from the inner cylinder 25. The outer cylindrical surface 24 and the inner cylindrical surface 25 are made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com