Processing technology for drilled and cooled cylinder liner

A processing technology and cylinder liner technology, which is applied in the field of drilling and cooling cylinder liner processing technology, can solve problems such as poor product quality, insufficient process flow, and insufficient piston precision, and achieve high product quality, high processing accuracy, and rigorous process flow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

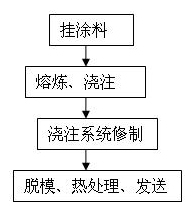

[0014] Such as figure 1 As shown, the drilling and cooling cylinder liner processing technology of the present invention comprises the following steps: Step a, hang the coating, prepare the metal mold and baffle plate, remove the residual coating in the inner cavity of the metal mold after being wetted with water, enter the kiln for preheating, The inner side of the front and rear baffles is pounded with water glass sand, scraped flat, hardened by adding CO, painted with lead powder, and put into the kiln together with the metal mold. The transformer is 250kw, and the capacity of the electric kiln is 210kw. Therefore, the electric furnace and the electric kiln cannot be powered at the same time. The paint is prepared, and the paint components are 150-200 mesh quartz powder, bentonite, powdery lead powder, flake lead powder, diatom Soil, water glass and water, the procedure for adding the above materials (except water glass) to the mixer: water, lead powder, bentonite, diatomac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com