Method for improving adhesive property of ramie fibre-thermoplastic resin interface

A thermoplastic resin and ramie fiber technology, which is applied in the field of improving the interface bonding performance between ramie fiber and thermoplastic resin, can solve the problems of high cost, long production process, and polluted equipment, and achieve high specific stiffness, low cost, and high specific strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Sample preparation: Soak all ramie fibers in absolute ethanol for 10 minutes, then place them in a standard state of 20°C and 65% relative humidity to balance, randomly extract fibers with a length of about 10 cm, and use double-sided adhesive tape and epoxy resin Fix it on the mold made of hard cardboard for use;

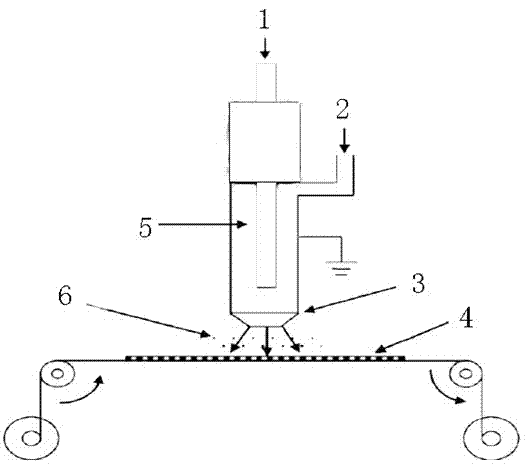

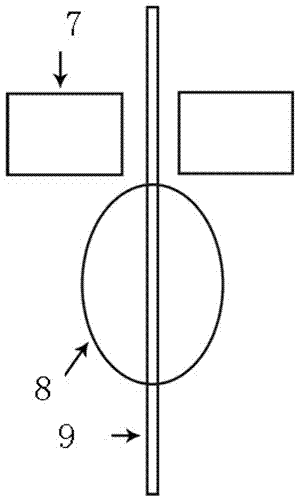

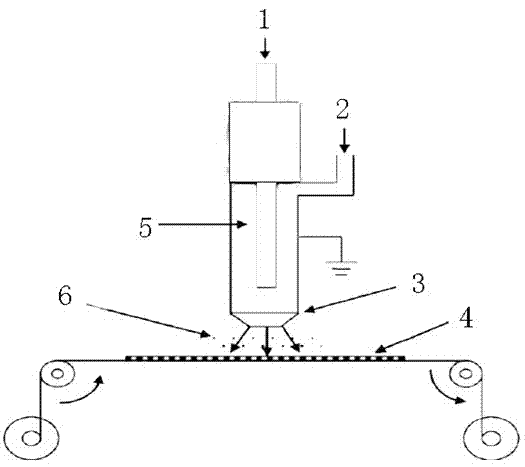

[0022] 2. Plasma surface treatment: using such as figure 1 The atmospheric pressure plasma jet equipment shown is fed with helium, the helium gas flow rate is 30LPM, the power frequency is 13.65MHZ, the power supply power is 42w, and the processing time of ramie fiber is 24s. The atmospheric pressure plasma jet equipment adopts Circular nozzle, nozzle height is 2mm, and nozzle diameter is 2.5cm, carries out surface treatment to above-mentioned ready-to-use fiber, forms one layer of hydrophobic vinyl film on fiber surface.

[0023] 3. Bonding performance test: The micro-debonding method is used to measure the bonding performance between the fiber and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com