Method for cultivating aerobic particle sludge by utilizing guanite

An aerobic granular sludge and struvite technology, applied in chemical instruments and methods, water/sludge/sewage treatment, biological water/sewage treatment, etc., can solve problems such as the disintegration of mature particles, achieve sufficient nutrient supply, The effect of shortening the culture period and not being prone to disintegration and apoptosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] Cultivation of Aerobic Granular Sludge by Nitrification and Phosphorus Removal Using Struvite

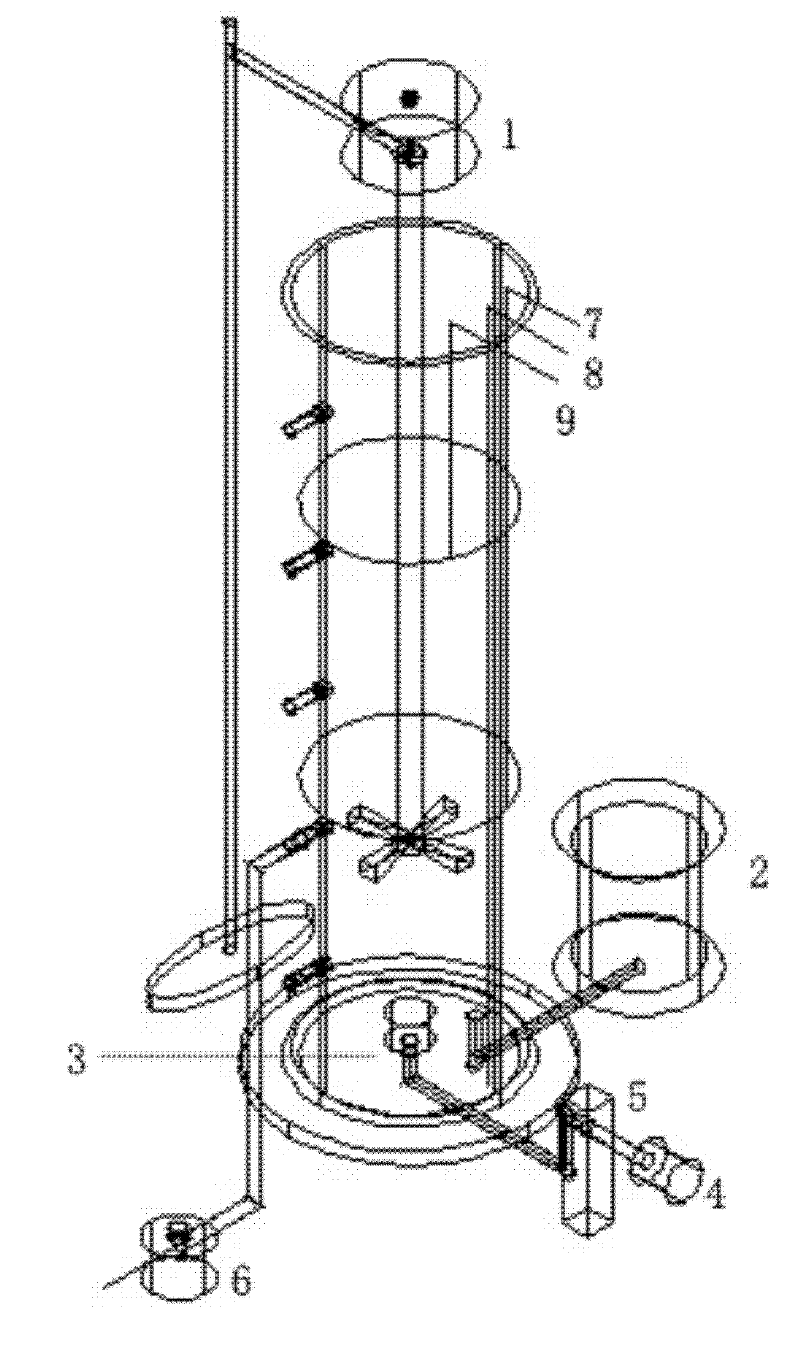

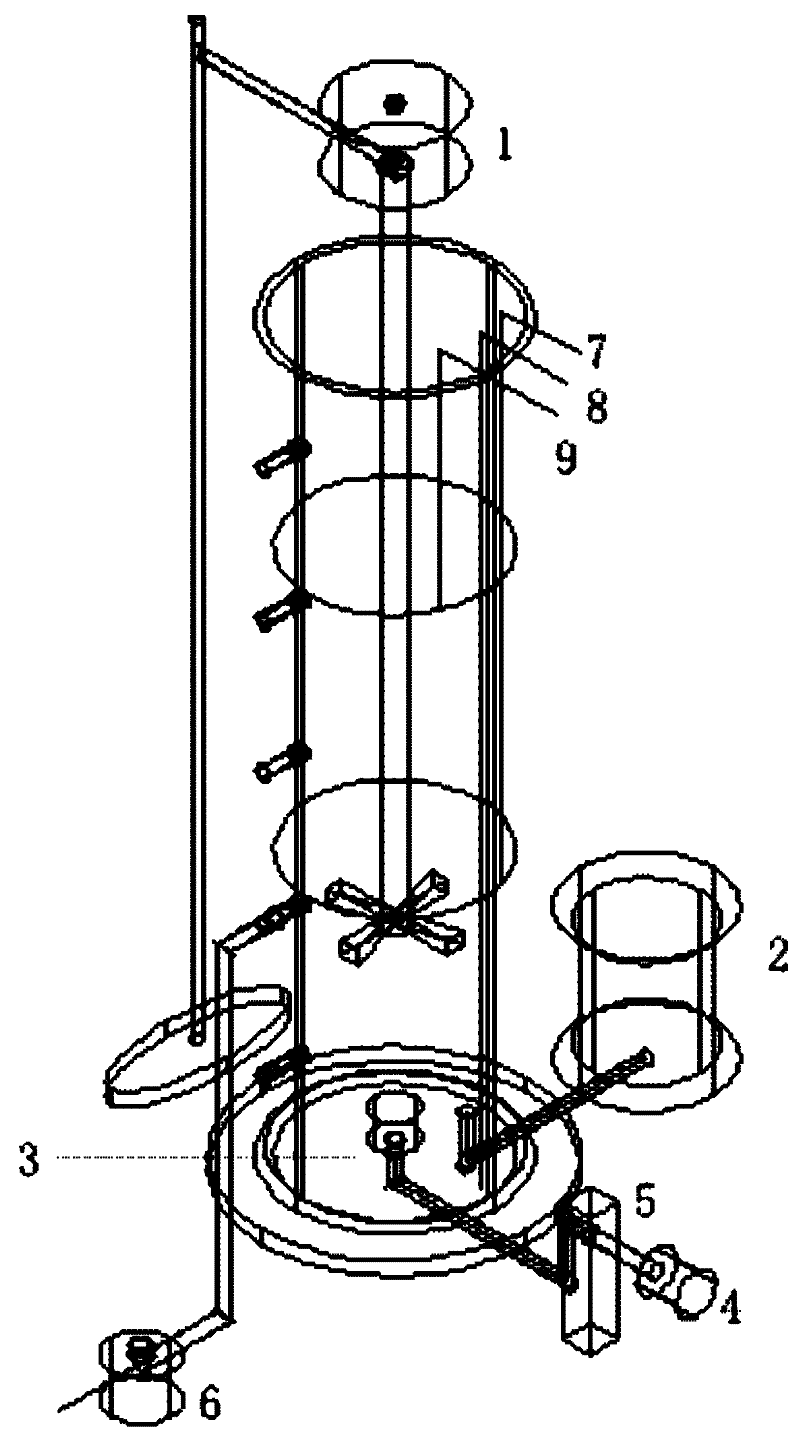

[0023]The SBR reactor is made of plexiglass in a cylindrical shape, with a diameter of 10cm, a height of 60cm, and an effective volume of 4L. The barrel wall is provided with a sampling hole, through which the liquid level gauge 8, the relay 7, the magnetic stirring controller 1, the bottom aeration head 3 and the solenoid valve 6 Control the process of water intake, stirring, aeration and drainage in SBR. The drain is at the bottom of the reactor at a height of 25 cm. The on-off of the drain is controlled by the solenoid valve 6, and the replacement ratio is 50%. The reaction cycle time is 4.5 hours, in which the water inflow is 5 minutes, and the water outlet is 0.5 minutes. The sedimentation time of the granular sludge formation stage is gradually reduced from 1 hour to 3 minutes. The aeration rate of the reactor is 0.20m3 / h, which is equivalent to a surface gas rising ve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com