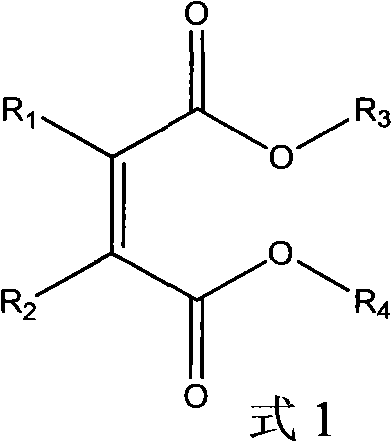

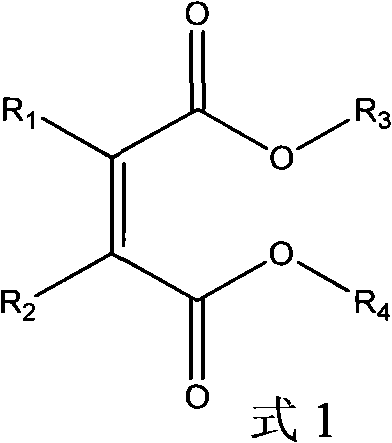

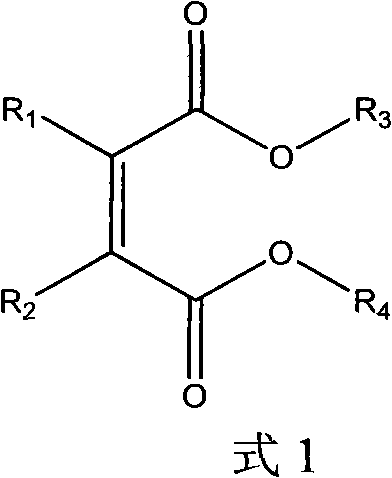

Diester-maleate-containing solid catalyst component for olefin polymerization and preparation method thereof

A technology of maleic acid diester and solid component is applied in the field of olefin polymerization catalyst solid component and its preparation, and can solve the problem of low isotacticity of polypropylene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Add 5g of anhydrous magnesium chloride, 23mL of isooctyl alcohol, 1mL of 2,3-diisobutyl di-n-butyl maleate, tetrabutyl titanate and 30mL of dry decane compound into the reaction flask, titanium The molar weights of tetrabutyl maleate and di-n-butyl 2,3-diisobutylmaleate are equal, and react at 130°C for 4 hours under the protection of nitrogen to fully dissolve anhydrous magnesium chloride to obtain a stable and uniform alcoholate solution, the reaction system was slowly lowered to room temperature.

[0054] (2) Add the homogeneous solution prepared above dropwise to a reactor fully replaced by nitrogen and equipped with 200ml titanium tetrachloride at -20°C within 1 hour. 1ml of 2,3-diisobutyldi-n-butylmaleate, continue to heat up for 30min until the temperature reaches 110°C, add 1.5ml of 2,3-diisobutyldi-n-butylmaleate, and react at this temperature 2 hours. After the reaction was completed, the liquid was filtered out, and 200 ml of titanium tetrachloride was ...

Embodiment 2

[0061] 2,3-diisobutyl di-n-butyl maleate is replaced by 2,3-diisobutyl diisobutyl maleate, and others are the same as in Example 1. Catalyst composition analysis results:

[0062] Titanium content: 2.17% (wt)

[0063] Magnesium content: 16.5% (wt)

[0064] Ester content: 8.1% (wt)

[0065] Polymerization result: catalytic activity 56,600gPP / gCat, polymer apparent density 0.46g / cm 3 , The isotacticity is 98.5%.

Embodiment 3

[0067] 2,3-diisobutyl di-n-butyl maleate is replaced with 2,3-diisopropyl di-n-butyl maleate, and others are the same as in Example 1. Catalyst composition analysis results:

[0068] Titanium content: 2.16% (wt)

[0069] Magnesium content: 16.5% (wt)

[0070] Ester content: 8.3% (wt)

[0071] Polymerization result: catalytic activity 55,400gPP / gCat, polymer apparent density 0.46g / cm 3 , The isotacticity is 98.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com