Laminar flow condenser for thermal decomposition and liquidation of biomass

A technology of biomass pyrolysis and condenser, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and special forms of dry distillation, etc. It can solve the problems of easy condensation in cooling towers, tar and charcoal ash bonding, and large cooling liquid flow. problems, to achieve the effect of easy cleaning, high heat exchange efficiency and large temperature gradient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

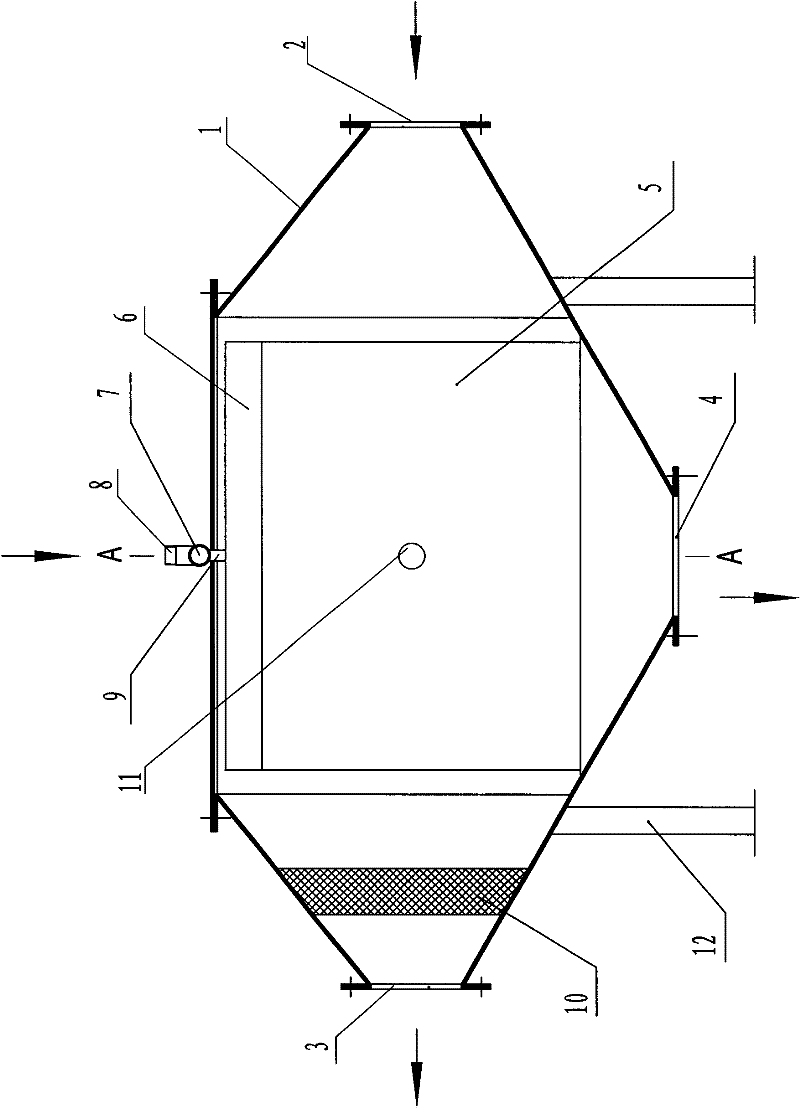

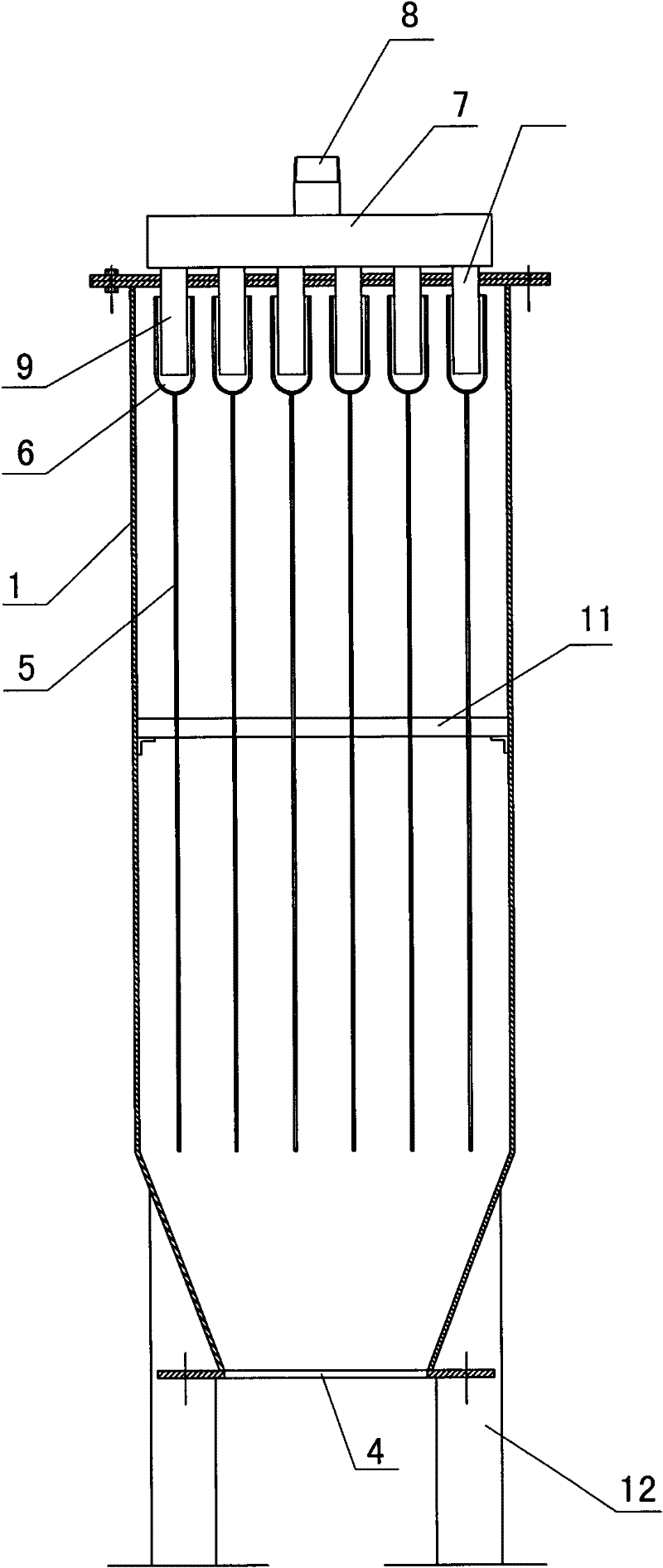

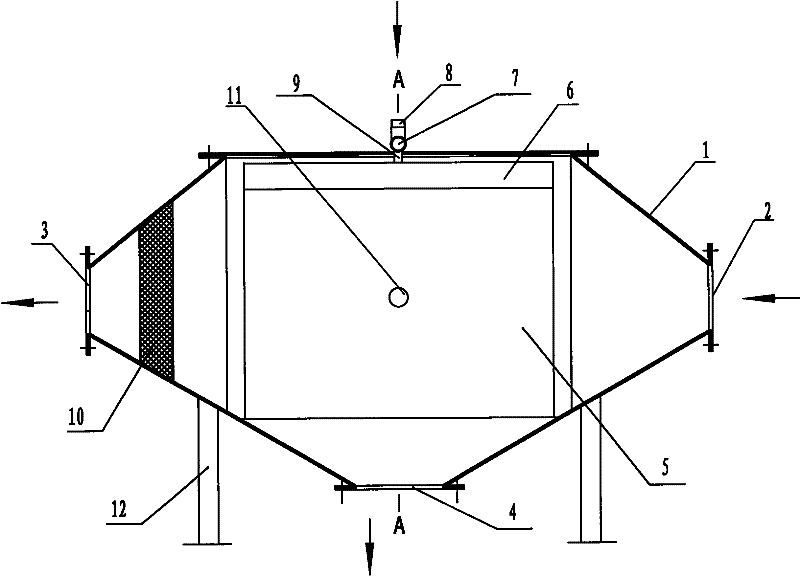

[0017] exist Figure 1-2 In the shown embodiment: the cylinder body 1 is installed horizontally on the support 12, the cross section of the cylinder body 1 is rectangular, one end is the pyrolysis gas inlet 2, and the other end is the pyrolysis gas outlet 3, the top of the cylinder body 1 is provided with A bio-oil inlet 8 and a bio-oil outlet 4 are provided at the bottom. A plurality of condensing plates 5 parallel to each other and equally spaced are arranged in the barrel 1 along the flow direction of the pyrolysis gas. The beam 11 passes through each condensing plate 5 horizontally in turn, and It is fixedly connected with each condensing plate 5, and the condensing plate 5 is fixedly installed in the cylinder body 1. An overflow groove 6 is provided on the top of each condensing plate 5. The overflow groove 6 is the same length as the condensing plate 5, and the overflow groove The bottom of 6 is fixedly installed on the top of the condensation plate 5, the side wall of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com