Method for recovering metallic copper and zinc from copper smelting ash

A technology for smelting soot and metallic copper from copper, which can be applied to the improvement of process efficiency, photography process, instruments, etc., and can solve the problems of high cost and large amount of zinc powder.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

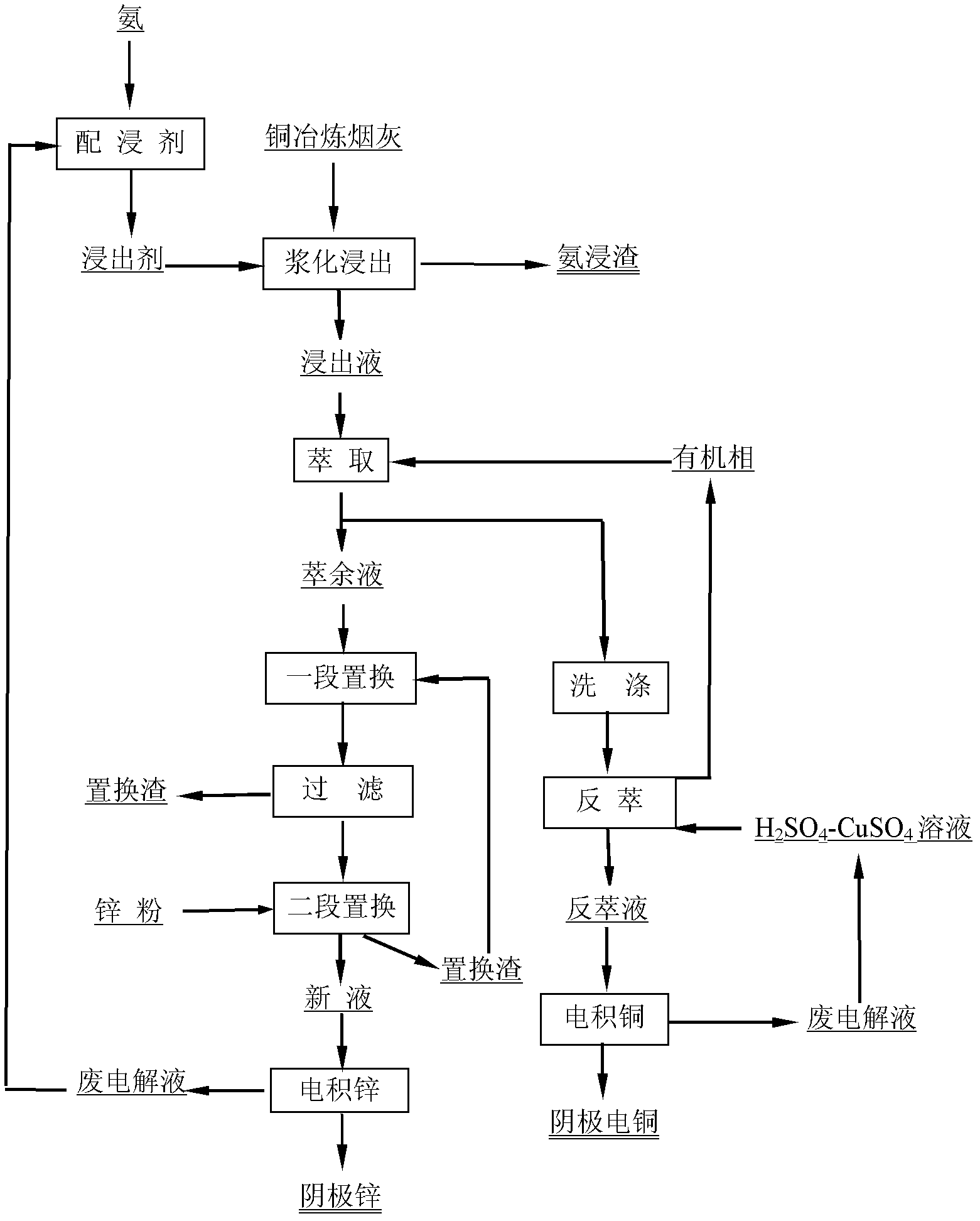

Method used

Image

Examples

Embodiment 1

[0051] A by-product of a secondary copper smelter is brass re-smelting ash, material composition (%): Zn 47.26, Pb 0.96, Cu 20.21, Ni 0.21, S 3.2, Cd 0.026, Fe 0.71, As 0.0042.

[0052] Using Zn(II)-NH 4 Cl-NH 3 The waste electrolyte of zinc electrowinning in the system is used as a leaching agent after mixing, containing Zn 2+ 12g / L, NH 4 Cl5.0mol / L, NH 3 2.5mol / L, leaching copper and zinc from copper smelting soot at room temperature, the solid-liquid ratio is 100g / L, and the leaching time is 0.5h.

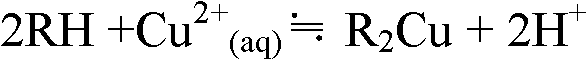

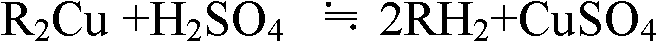

[0053] The solution obtained after filtration and separation contains (g / L): Zn 2+ 58.56, Cu 2+ 19.85, Ni 2+ 0.18, Cd 2+ 0.02, Pb 2+ 0.058L. Using 30% LIX-84-IT kerosene as the extraction agent, at room temperature, O / A is 1.5 / 1.0, and the extraction order is 3, copper is selectively extracted from the leachate; the loaded organic phase is washed in two stages, O / A=50 / 1; then use Cu 2+ 12.1g / L, H 2 SO 4 220g / L of waste electrolyte stripping copper, O / A=3 / 1 strippin...

Embodiment 2

[0058] A factory brass recycled soot, material composition (%): Zn 50.93, Pb 2.21, Cd 0.40, Fe 1.05, Cu 12.88, Ni 0.24, As 0.0051.

[0059] Newly configured NH 4 Cl-NH 3 The solution is a leaching agent, containing Zn 2+ 0g / L, NH 4 Cl 5.5mol / L, NH 3 2.0mol / L, stirring and leaching copper and zinc from copper smelting soot at room temperature, the solid-liquid ratio is 120g / L, and the leaching time is 1.0h.

[0060] After filtration and separation, the liquid (g / L) contains: Zn 2+ 60.58, Cu 2+ 14.46, Ni 2+ 0.24, Cd 2+ 0.41, Pb 2+ 0.018. Using 30% LIX-84-IT kerosene as the extraction agent, extract copper from the leaching solution under the conditions of normal temperature, O / A ratio of 1 / 1, and extraction stages of 2. The loaded organic phase is washed in two stages, O / A = 30 / 1; then use the newly prepared sulfuric acid solution to strip copper, and the newly prepared solution contains H 2 SO 4 250g / L, O / A=4 / 1, stripping to get Cu-containing 2+ 57.6g / L solution, e...

Embodiment 3

[0065] Copper converter soot in a factory, material composition (%): Cu 2.98, Zn 9.39, Pb 22.31, Bi 1.85, Fe 8.52, Cd 0.64, Fe 1.05, As 2.89, In 0.035.

[0066] Using Zn(II)-NH 4 Cl-NH 3 The waste electrolyte of zinc electrowinning in the system is used as a leaching agent, containing Zn 2+ 20.0g / L, NH 4 Cl5.5mol / L, NH 3 2.0mol / L, solid-liquid ratio is 300g / L, after stirring and leaching at room temperature for 2.5h, the supernatant is open-circuited to recover copper and zinc; the underflow is added with leaching agent and then ball milled for 0.5h, and the filtered solution is returned to stir to leach soot.

[0067] Liquid composition after filtration and separation (g / L): Zn 2+ 45.91, Cu 2+ 8.96, Ni 2+ 0.26, Cd 2+ 1.77, Pb 2+ 0.008, As 3+ 0.003. Using 10% LIX-84-IT kerosene as the extraction agent, extract copper from the leaching solution at room temperature, O / A is 2 / 1, and the extraction stage is 1; the loaded organic phase is washed in two stages, O / A =10 / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com