Annular capacitor with power conversion components

A capacitor and film capacitor technology, applied in the direction of tubular capacitors, wound capacitors, fixed capacitor terminals, etc., can solve the problem of voltage increase at the switch, reduce voltage overshoot, increase long-term reliability, and reduce effective series inductance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

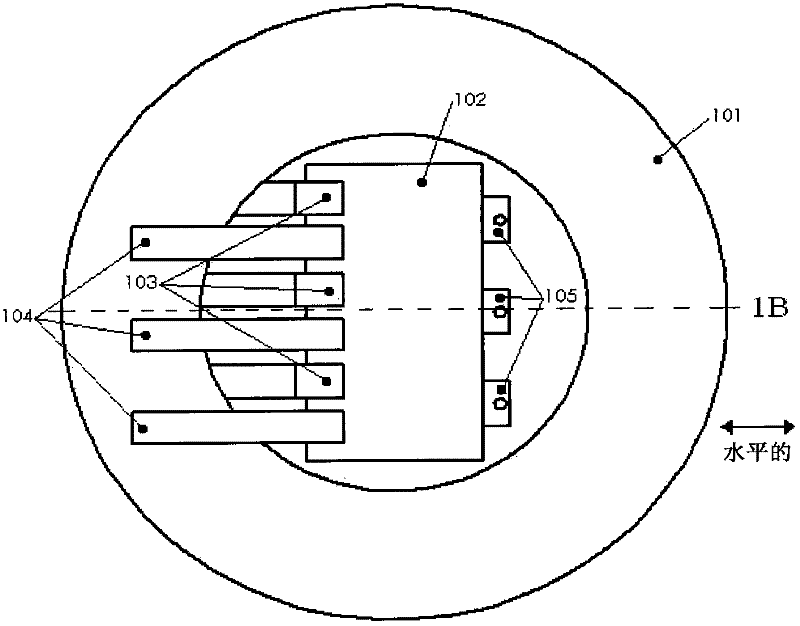

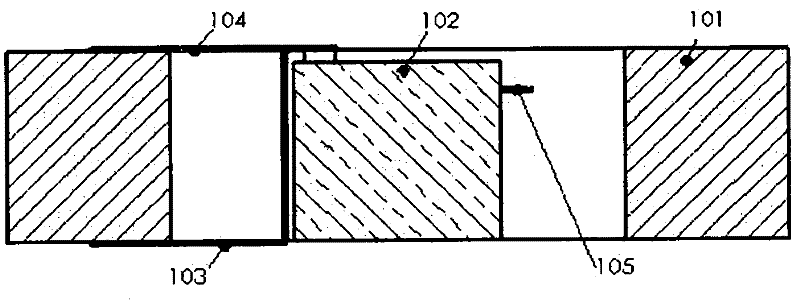

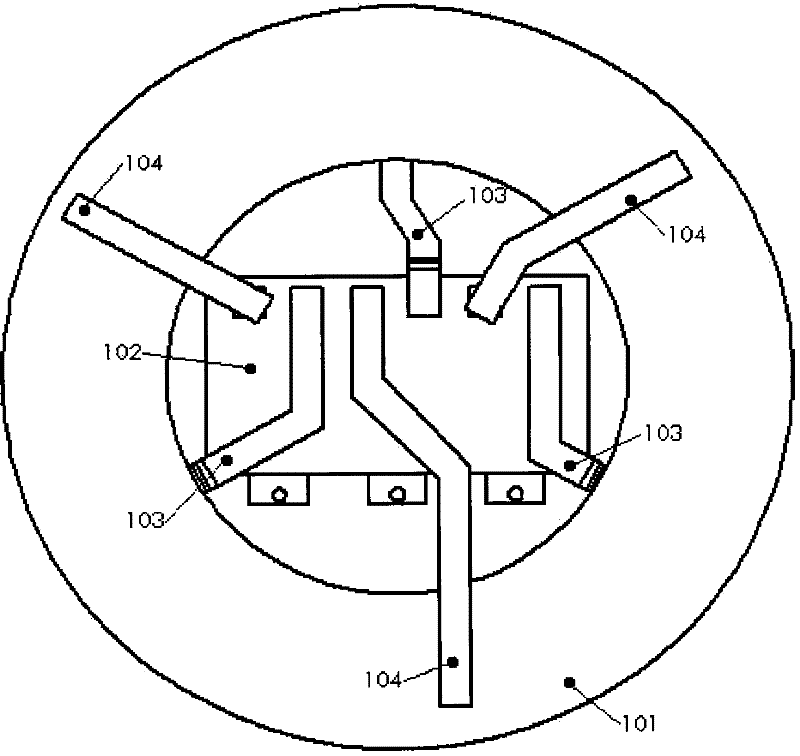

[0034] exist figure 1 A metallized film polymer ring capacitor with a single power conversion component is shown in . The annular capacitor body 101 has a variable center hole radius, allowing the power conversion component 102 to be tailored to specific specifications, leaving the necessary space for the component's upper terminal 104 , lower terminal 103 and output terminal 105 . exist figure 1 In , the terminals are positioned for the shortest possible path using typical commercially available power conversion components. The outer diameter and thickness of the ring capacitor can then be selected to achieve the desired capacitance for the power conversion application. exist Figure 1BThe thickness of the ring capacitor is indicated in (address). The depth of the ring capacitor 101 is made to match the height of the power conversion component 102 so that the terminals 103 and 104 can maintain the shortest distance for connection to the capacitor and thus the lowest con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com