Method for preparing nano aluminum by utilizing chemical method

A technology of nano-aluminum and lithium-aluminum hydride is applied in the field of thermally decomposing aluminum compounds and preparing nano-aluminum, which can solve the problems of difficulty in controlling the particle size of nano-aluminum, complicated operation and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The preparation method according to the present invention is specifically described below.

[0017] Step 1), under the protection of an inert gas, add the raw material inorganic aluminum salt compound, lithium aluminum hydride, phosphorus-containing additives and organic solvent into the reactor, and disperse the raw material into the organic solvent by stirring or ultrasonic method.

[0018] In the preparation method of the present invention, the main function of this step is to disperse the raw material inorganic aluminum salt compound and lithium aluminum hydride as the reactant in the organic solvent as the reaction medium, and disperse the phosphorus-containing additive that plays a protective role Into the organic solvent, so that the reaction substance and the protective substance are uniformly dispersed in the medium, so as to facilitate the subsequent heating reaction.

[0019] Inorganic aluminum salt compound is the main raw material of the method of the prese...

Embodiment 1

[0043] In the case of nitrogen protection, 0.267g (2mmol) of anhydrous AlCl was charged into a three-neck round bottom flask 3 , 0.2277g (6mmol) LiAlH 4 , 7.869g (30mmol) TPP (triphenylphosphine) and 20ml xylene, stirring constantly. The three ports were sealed with rubber stoppers; ultrasonic dispersion was performed for 10-120 minutes.

[0044] Under the condition of stirring, slowly increase the temperature to 160°C at a heating rate of 2°C / min. During the reaction, nitrogen gas is continuously fed in. The reaction time is 1 hour. Observe that the color of the solution changes from gray to black. When the reaction is over, stop heating , the temperature was lowered to room temperature under the condition of continuously blowing nitrogen gas.

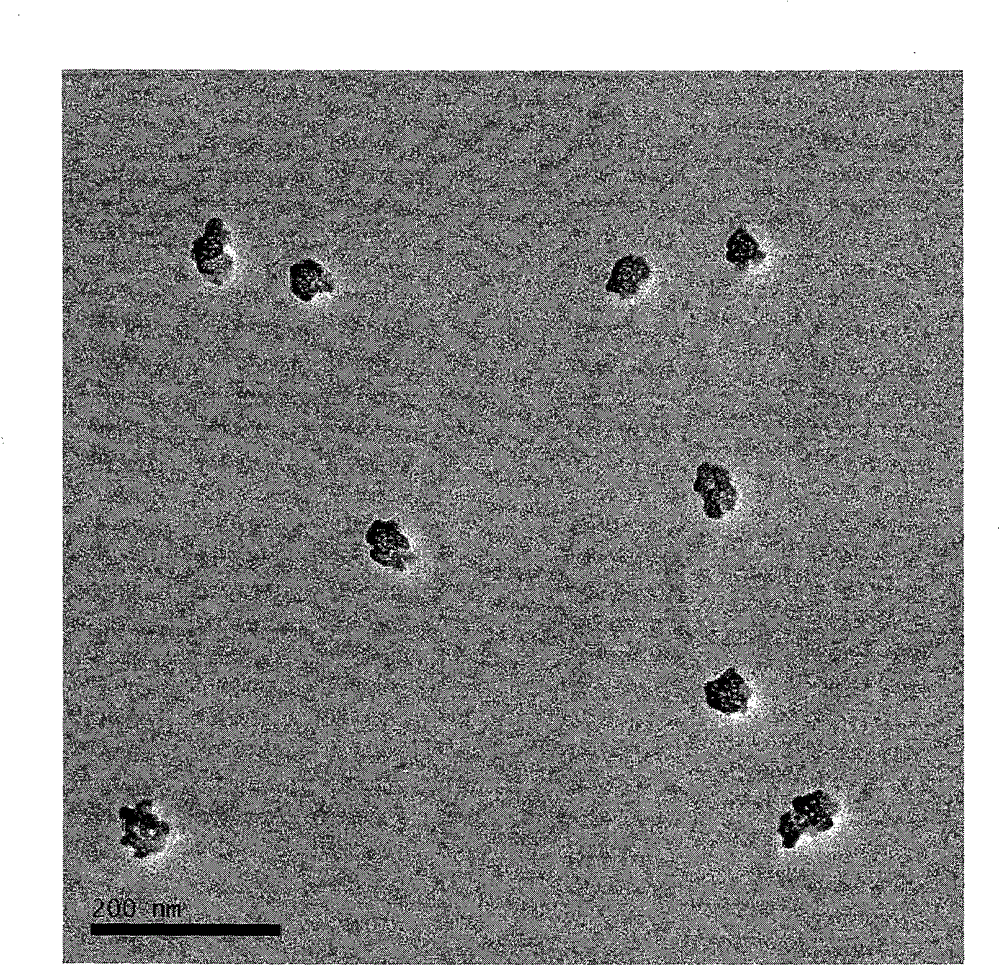

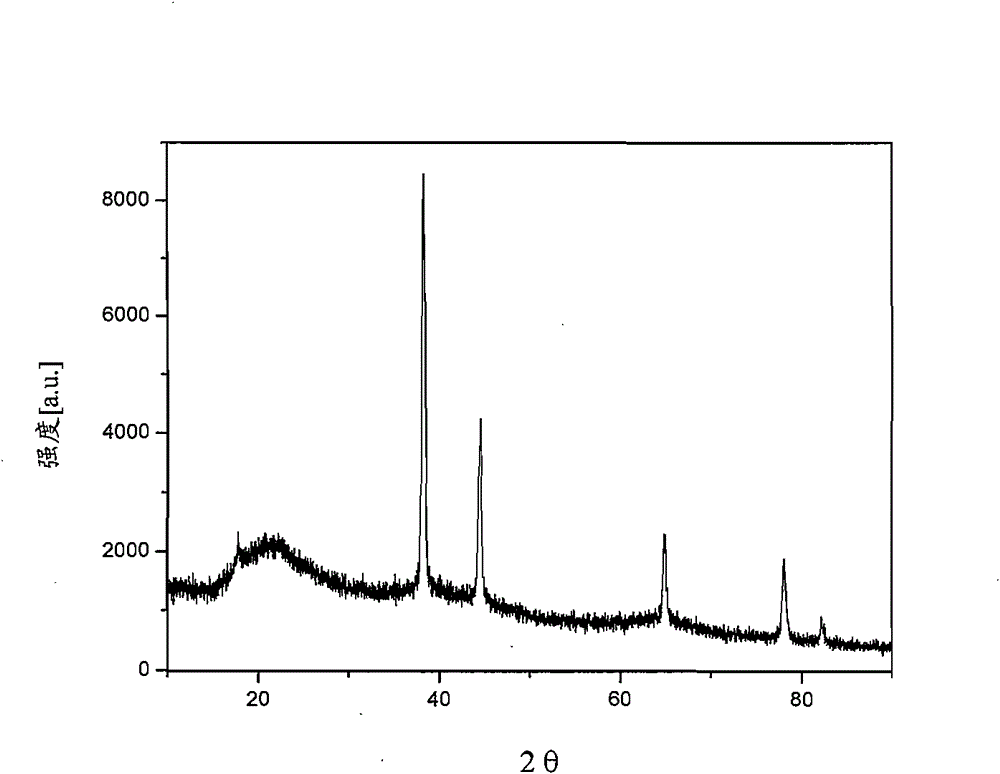

[0045] After taking out the reaction product, put it into a centrifuge tube for centrifugation, pour off the supernatant, wash the reaction product with methanol, tetrahydrofuran and acetone respectively, vacuum-dry the obtained pro...

Embodiment 2

[0049] In the case of nitrogen protection, 0.267g (2mmol) of anhydrous AlCl was charged into a three-neck round bottom flask 3 , 0.2277g (6mmol) LiAlH 4 , 7.869g (30mmol) TPP (triphenylphosphine) and 20ml xylene, stirring constantly. The three ports were sealed with rubber stoppers; ultrasonic dispersion was performed for 10-120 minutes.

[0050] Under the condition of stirring, the temperature was slowly raised to 170° C. with a heating rate of 3° C. / min. During the reaction, nitrogen gas was continuously fed into it. The reaction time was 1 hour and 30 minutes. The color of the solution was observed to change from gray to black, and the reaction was over. Heating was stopped and the temperature was lowered to room temperature under constant nitrogen sparging.

[0051] After taking out the reaction product, put it into a centrifuge tube for centrifugation, pour off the supernatant, wash the reaction product with ethanol, toluene and ether respectively, vacuum-dry the obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com