Preparation method of zinc oxide nanorod

A zinc oxide nanorod, zinc salt technology, applied in zinc oxide/zinc hydroxide, nanotechnology and other directions, can solve the problems of small particle size of nano powder, high temperature sintering, complicated process, etc., and achieve low cost of raw materials and controllable reaction conditions. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

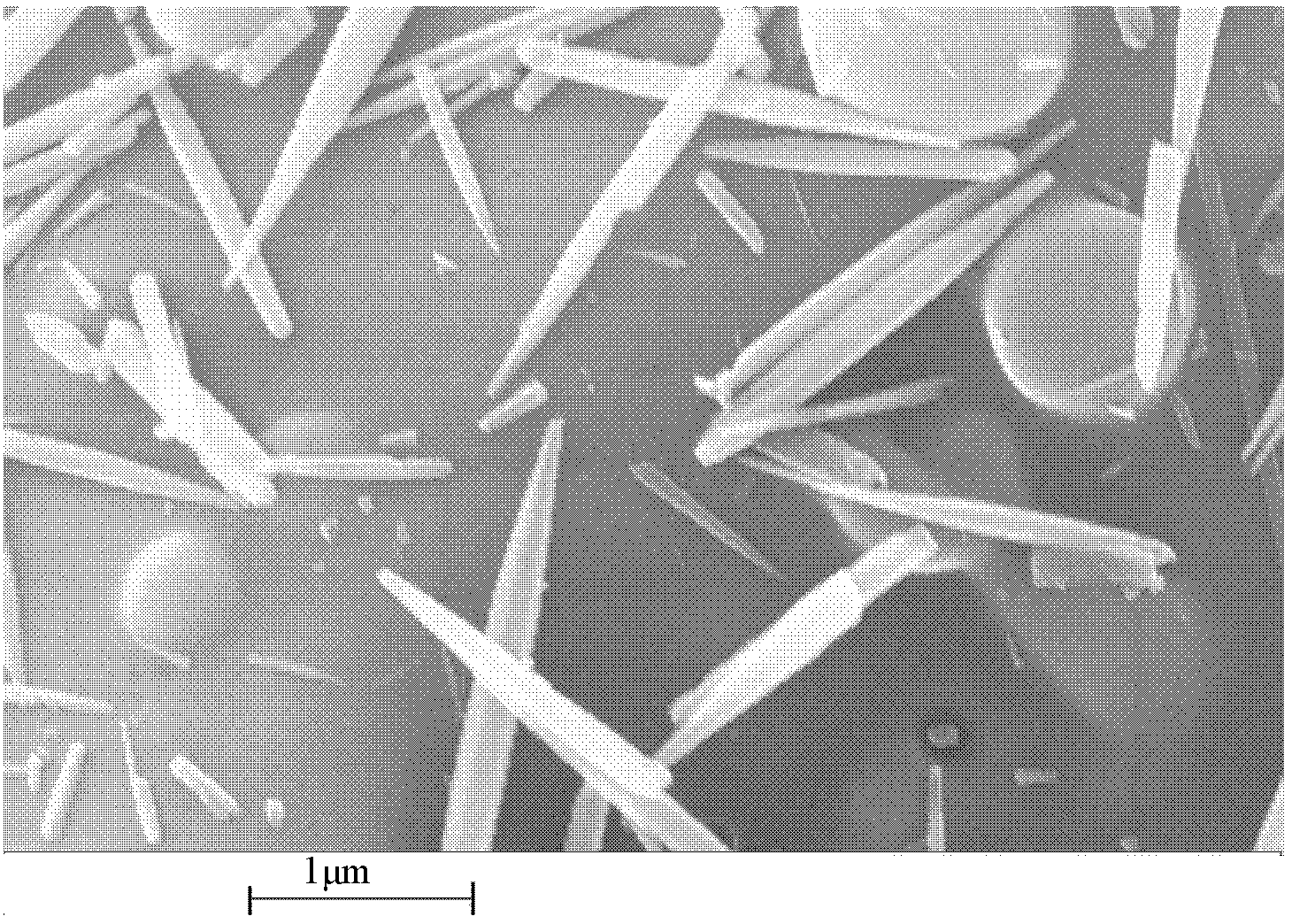

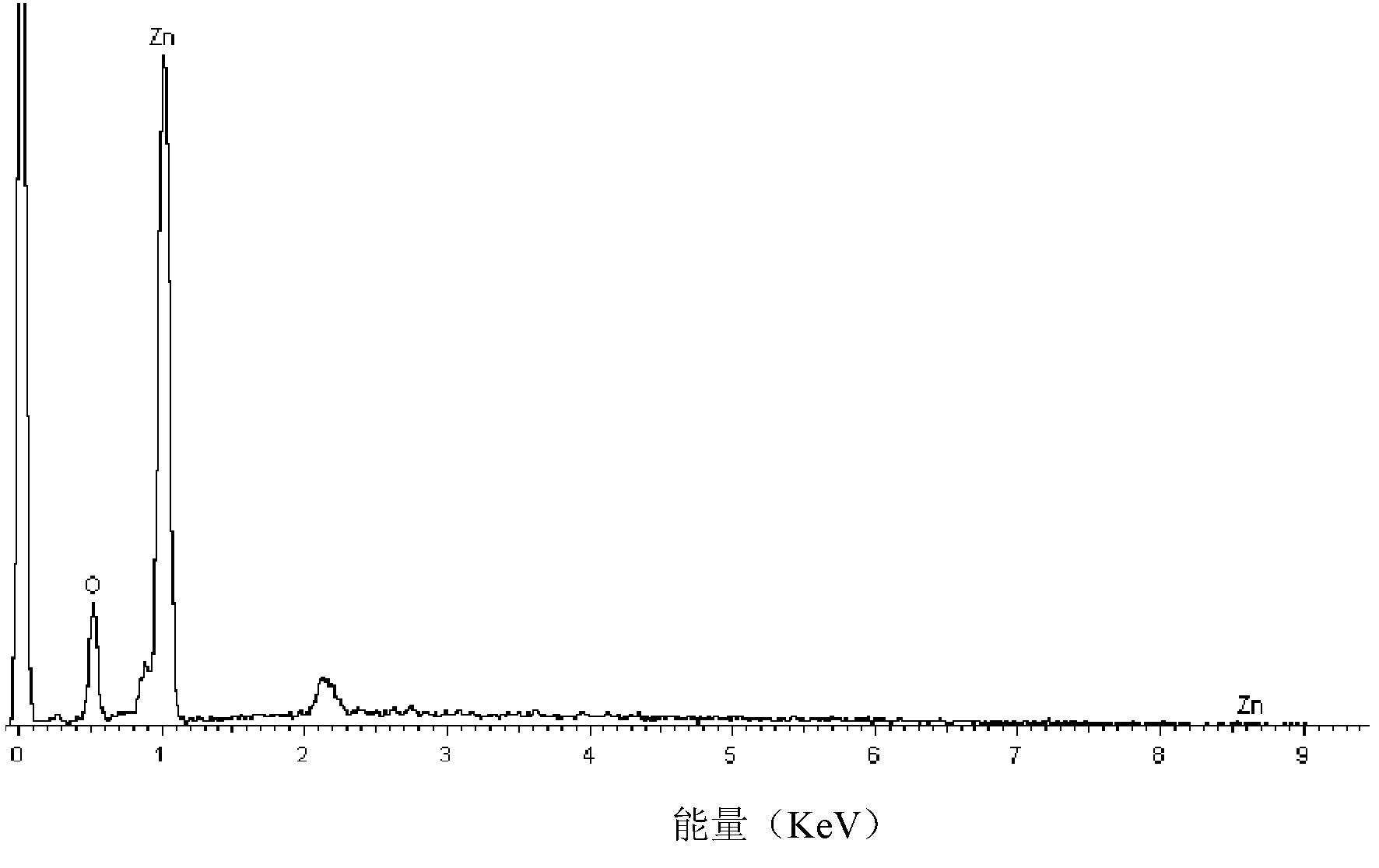

[0015] 2.97g of Zn(NO 3 ) 2 ·6H 2 O and 4g of NaOH were dissolved in 25mL of distilled water, and then the Zn(NO 3 ) 2 The solution is injected into the NaOH solution, a large amount of white flocculent precipitates appear in the solution, stir well, the white flocs dissolve, transfer the mixed solution to a 100mL polytetrafluoroethylene autoclave, heat at 70°C for 3 hours, filter and wash to form white precipitate, dried.

Embodiment 2

[0017] Dissolve 2.97g of Zn(NO3)2·6H2O and 4g of NaOH in 25mL of distilled water respectively, then inject the Zn(NO3)2 solution into the NaOH solution, a large amount of white flocculent precipitates appear in the solution, stir well, the white flocculent The solids were dissolved, and the mixed solution was transferred to a 100mL polytetrafluoroethylene autoclave, heated in water at 70°C for 5h, filtered, washed, and the resulting white precipitate was dried.

Embodiment 3

[0019] Dissolve 2.97g of Zn(NO3)2·6H2O and 4g of NaOH in 25mL of distilled water respectively, then inject the Zn(NO3)2 solution into the NaOH solution, a large amount of white flocculent precipitates appear in the solution, stir well, the white flocculent The solids were dissolved, and the mixed solution was transferred to a 100mL polytetrafluoroethylene autoclave, heated in water at 70°C for 24 hours, filtered, washed, and the resulting white precipitate was dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com