Method for extracting and separating ganoderma lucidum polysaccharide from ganoderma lucidum sporocarp

A technology of Ganoderma lucidum fruiting bodies and Ganoderma polysaccharides, which is applied in the field of extraction and separation of Ganoderma lucidum polysaccharides, can solve problems such as difficulties in large-scale production, achieve the effects of reducing solvent consumption, ensuring activity, and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

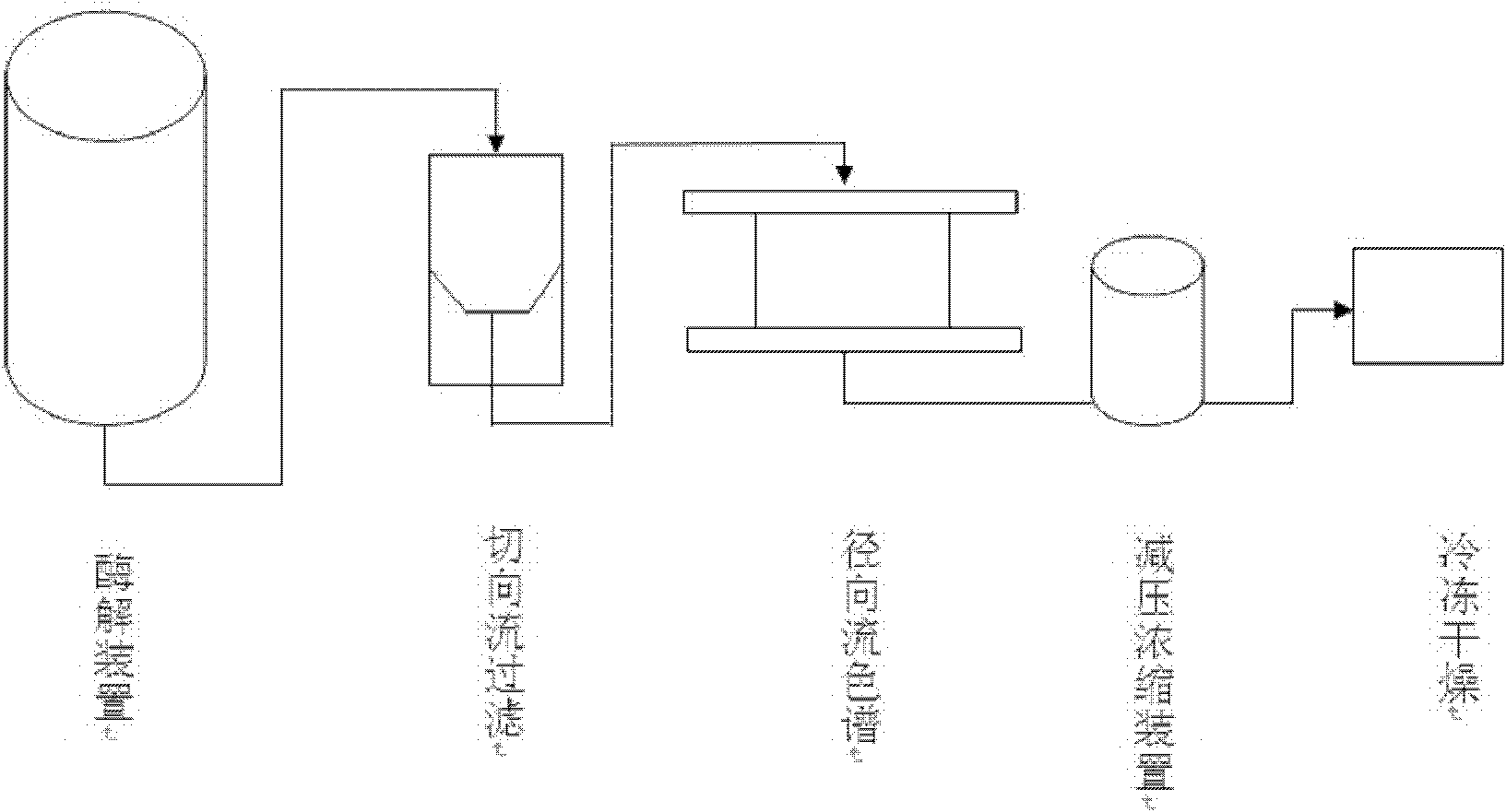

Method used

Image

Examples

Embodiment 1

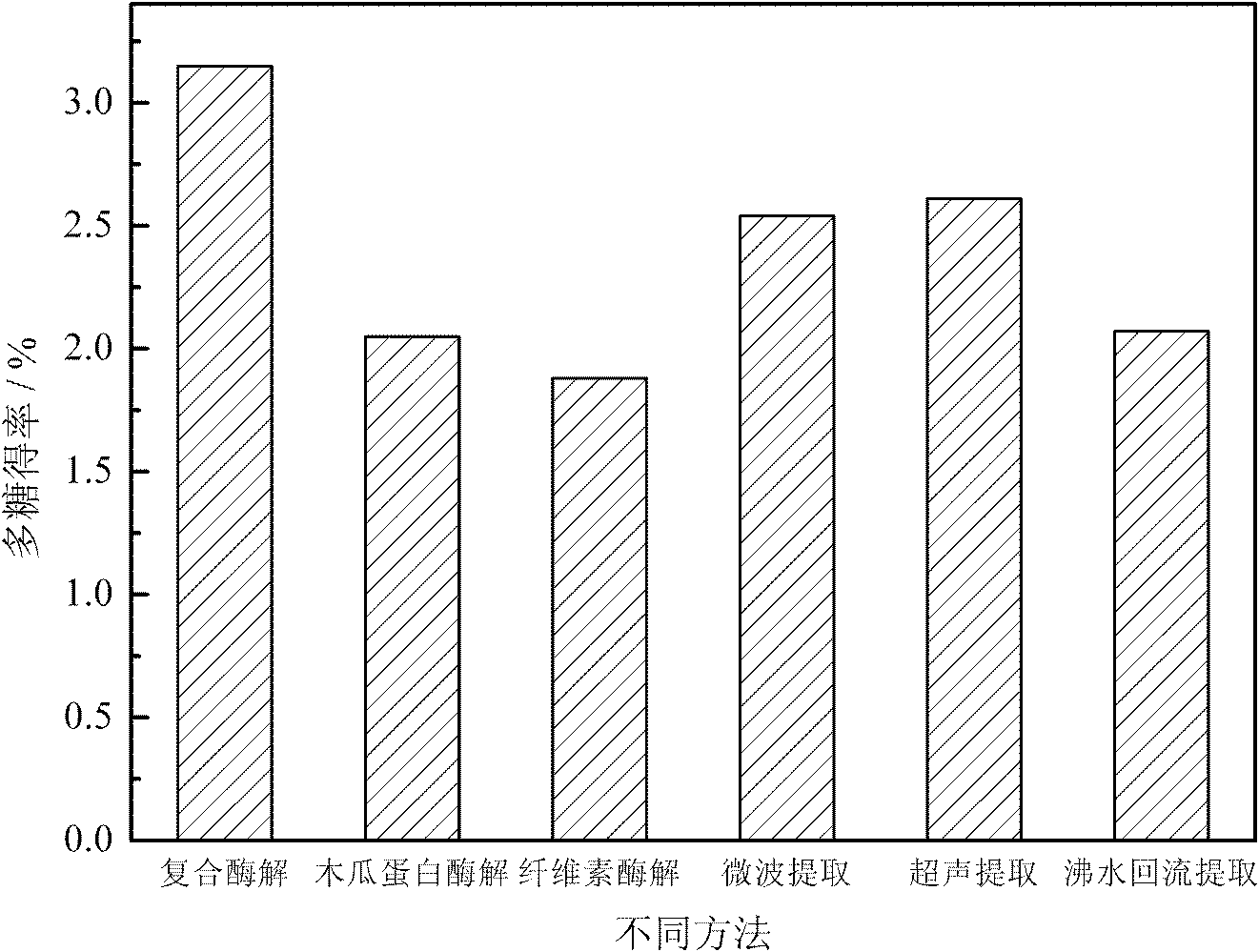

[0031] (1) Compound enzymatic hydrolysis to extract polysaccharides from Ganoderma lucidum fruiting bodies: select the crushed Ganoderma lucidum fruiting bodies that pass through a 100-mesh sieve, take 50.0 g of Ganoderma lucidum fruiting body powder, add it to 1000 g of water, and adjust the pH of the solution to 6.8 with saturated calcium hydroxide solution, Add 1.5g compound enzyme, the compound enzyme is papain (Shanghai Lanji Technology Development Co., Ltd., 1 million U / g) and cellulase (Zhangjiagang Jinyuan Biochemical Co., Ltd., 80,000 U / g) mass ratio 2:1 The mixture was placed in a constant temperature water bath at 55°C, stirred at a constant speed for 2 hours, centrifuged at 4000rpm for 10 minutes, and the supernatant was taken to obtain the enzymatic hydrolysis solution;

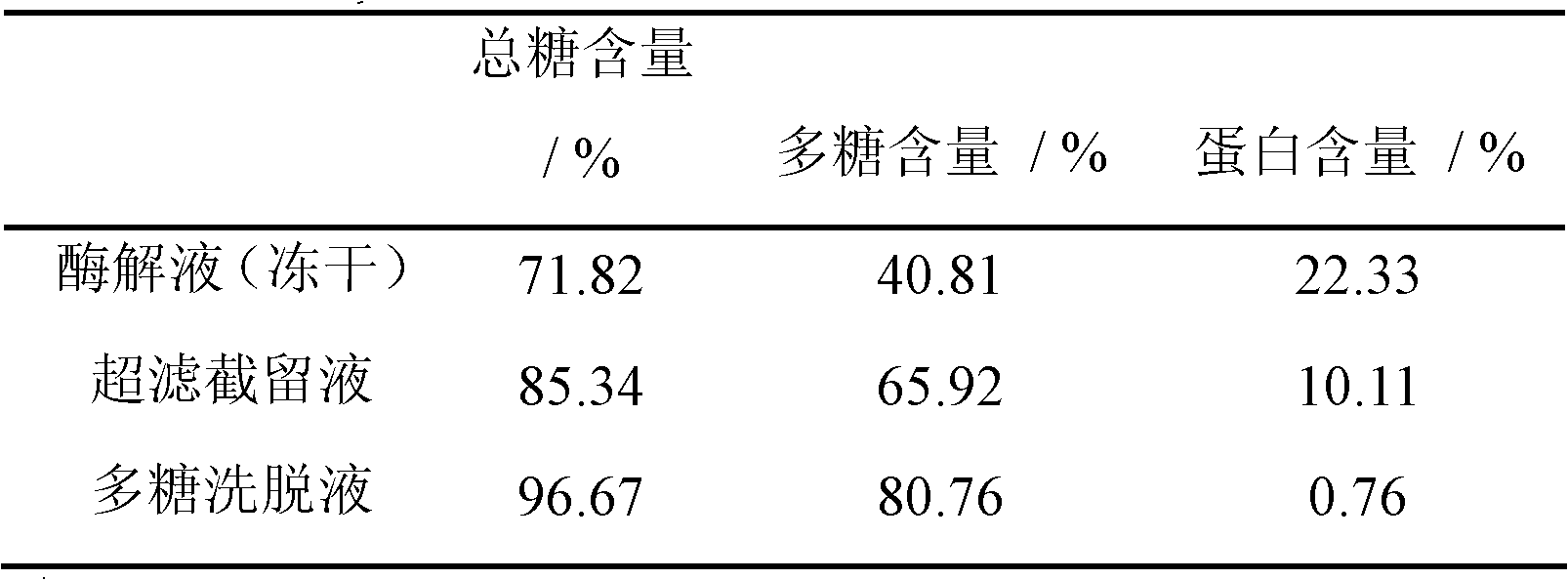

[0032] (2) Tangential flow ultrafiltration membrane concentrated enzymatic hydrolysis solution: the enzymatic hydrolysis solution enters the tangential flow filtration system (Congent M, Millipore...

Embodiment 2

[0040] (1) Compound enzymatic hydrolysis to extract polysaccharides from Ganoderma lucidum fruiting body: select the crushed Ganoderma lucidum fruiting body that has passed through a 100-mesh sieve, take 50.0 g of Ganoderma lucidum fruiting body powder, add it to 500 g of water, and adjust the pH of the solution to 6.0 with saturated calcium hydroxide solution. Add 1.2g compound enzyme, the compound enzyme is papain (Shanghai Lanji Technology Development Co., Ltd., 1 million U / g) and cellulase (Zhangjiagang Jinyuan Biochemical Co., Ltd., 80,000 U / g) mass ratio 1:1 The mixture was placed in a constant temperature water bath at 40°C, stirred at a constant speed for 1 hour, centrifuged at 4000rpm for 12 minutes, and the supernatant was taken to obtain the enzymatic hydrolysis solution;

[0041] (2) Tangential flow ultrafiltration membrane concentrated enzymolysis solution: the enzymolysis solution enters the tangential flow filtration system, selects an ultrafiltration membrane wi...

Embodiment 3

[0046] (1) Complex enzymatic hydrolysis to extract polysaccharides from Ganoderma lucidum fruiting bodies: select the crushed Ganoderma lucidum fruiting bodies that pass through a 100-mesh sieve, take 50.0 g of Ganoderma lucidum fruiting body powder, add it to 1500 g of water, and adjust the pH of the solution to 4.5 with a saturated calcium hydroxide solution. Add 0.5g compound enzyme, compound enzyme is papain (Shanghai Lanji Technology Development Co., Ltd., 1,000,000 U / g) and cellulase (Zhangjiagang Jinyuan Biochemical Co., Ltd., 80,000 U / g) mass ratio 4:1 The mixture was placed in a constant temperature water bath at 65°C, stirred at a constant speed for 3 hours, centrifuged at 4000rpm for 12 minutes, and the supernatant was taken to obtain the enzymatic hydrolysis solution;

[0047] (2) Tangential flow ultrafiltration membrane concentrated enzymolysis solution: the enzymolysis solution enters the tangential flow filtration system, selects an ultrafiltration membrane with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com