High-viscosity asphalt modifier, modified asphalt and asphalt mixture

An asphalt modifier and modified asphalt technology, applied in the field of asphalt and asphalt mixture, asphalt modifier, can solve the problems of low porosity of asphalt concrete pavement, and achieve the effects of preventing aging, increasing porosity, and preventing flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1: Styrene-butadiene-styrene copolymer, styrene-butadiene rubber, rosin, sulfur and carbon black are weighed according to the ratio of 4:2:8:0.15:0.1, and then the four substances are put into The high-speed mixer is fully mixed, and the four substances are fully mixed, and then the materials are added to the twin-screw extruder for heating and extrusion. After cooling and drying, the extruded strip modifier is sent to the Pelletizing is carried out in the pelletizer, and the cut pellets are high-viscosity asphalt modifier.

Embodiment 2

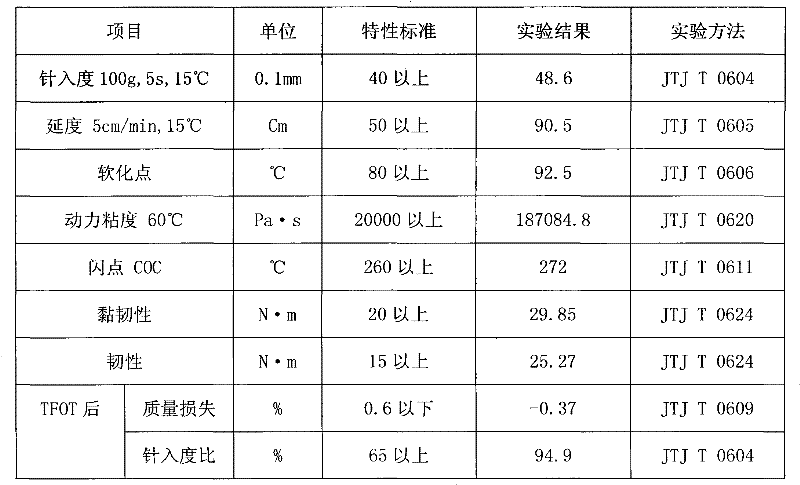

[0018] Example 2: The high-viscosity asphalt modifier prepared in Example 1 was added to the heavy traffic asphalt according to the needs of the actual project, and the mixing ratio of the heavy traffic asphalt and the high-viscosity asphalt modifier was 84:16, and then prepared into The required high-viscosity modified asphalt and the performance indicators of the high-viscosity modified asphalt containing high-viscosity asphalt modifier all meet the relevant national standards, as shown in Table 1.

[0019] Table 1

[0020]

Embodiment 3

[0021] Example 3: During the production process of the mixture, the high-viscosity modified asphalt prepared in Example 2 was put into the mixing building and mixed with the aggregate, wherein the high-viscosity modified asphalt accounted for 5% of the total weight of the mixture , and then prepare high-viscosity asphalt mixture for road construction and so on. The performance indicators of the prepared high-viscosity asphalt mixture are shown in Table 2.

[0022] Table 2

[0023] Test items

[0024] It can be seen from the above experimental data that the high-viscosity asphalt and high-viscosity asphalt mixture prepared by using this high-viscosity asphalt modifier have excellent performance in all aspects, fully meeting the national requirements for high-viscosity asphalt and high-viscosity asphalt. Relevant technical standards for mixtures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com