Real-time monitoring device for online writing weak optical fiber Bragg grating and application method thereof

A technology of weak fiber Bragg grating and monitoring device, which is applied in the coupling of optical waveguide, testing optical performance, etc., can solve the problems of difficult to ensure the strength and integrity of fiber Bragg grating, online monitoring of weak fiber Bragg grating, fiber damage, etc., and achieve shortening of fiber positioning Clamping time, convenient replacement, fast and convenient fiber optic docking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

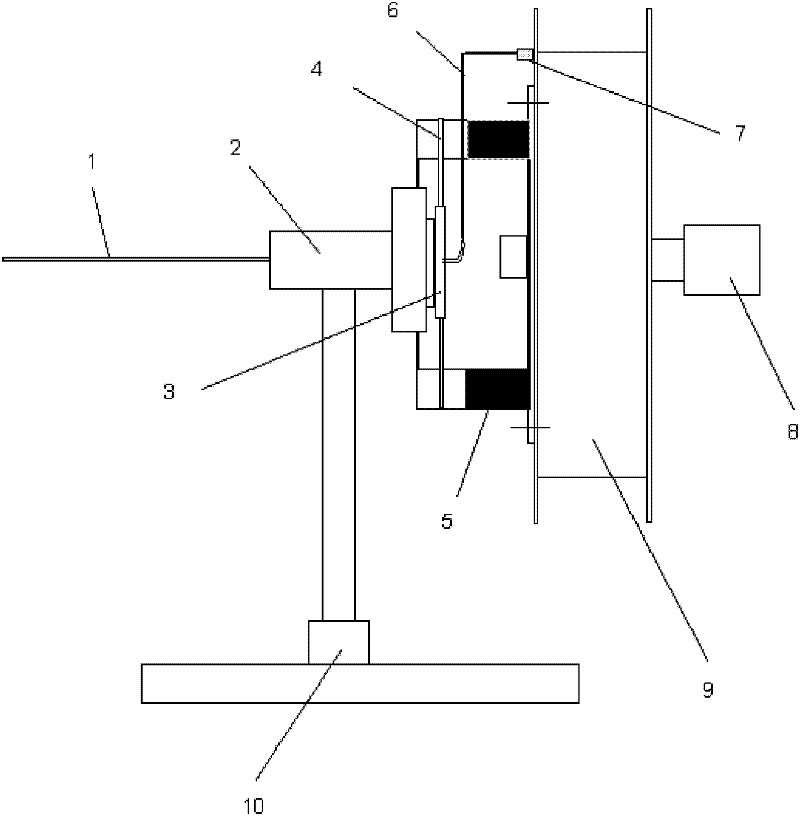

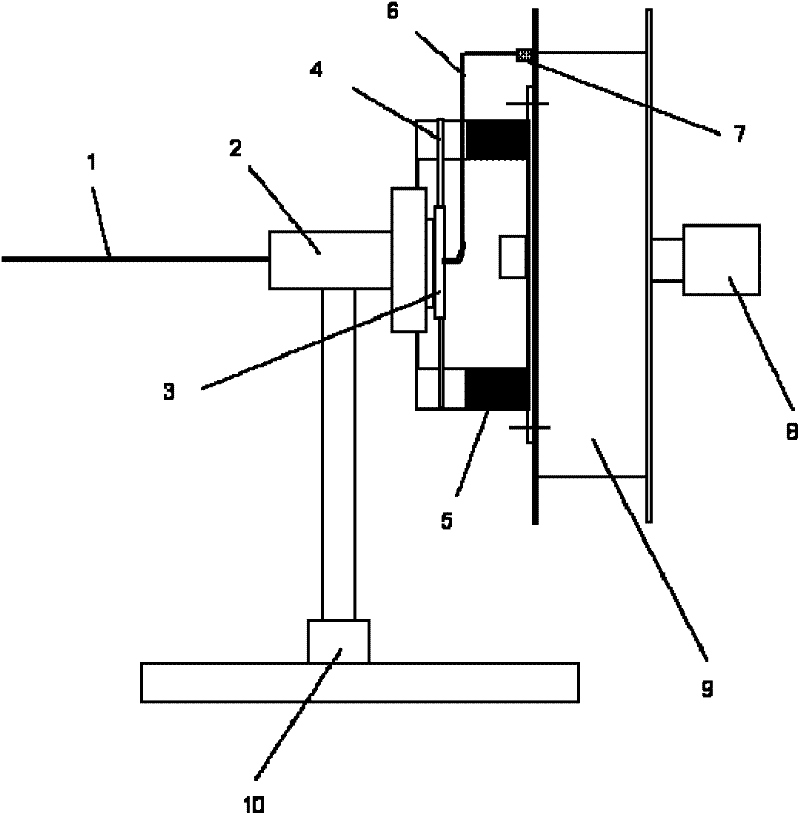

[0026] Such as figure 1 As shown, on the whole, the patent of the present invention mainly includes two parts: the quick combination and separation mechanism of the lever and the dial and the quick positioning clamper for the optical fiber. The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

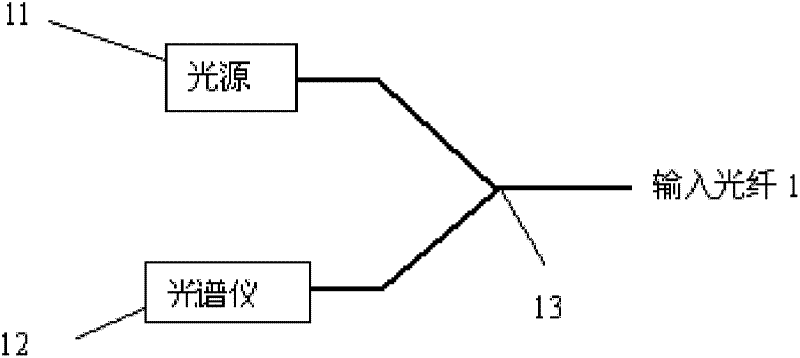

[0027] An on-line monitoring device for weak fiber grating writing status in the fiber drawing process of the present invention, the device includes an input optical fiber 1, a stator 2, a rotor 3, a lever 4, a cylinder 5, an output optical fiber 6, and a V-groove quick connection 7, motor 8, take-up reel 9, sliding guide rail 10, light source 11, spectrometer 12 and Y-shaped splitter 13; stator 2 is supported on sliding guide rail 10, one end of stator 2 is connected to input optical fiber 1, and rotor 3 is connected to output optical fiber 6 are connected, the stator 2 and the rotor 3 are non-contact coupling l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com