Surfacing flux-cored wire and method for enhancing tenacity of surfacing deposited metal

A technology of flux-cored welding wire and welding wire, used in metal processing equipment, welding medium, welding equipment, etc., can solve the problems of thermal fatigue and wear resistance, and achieve the effect of improving strength and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

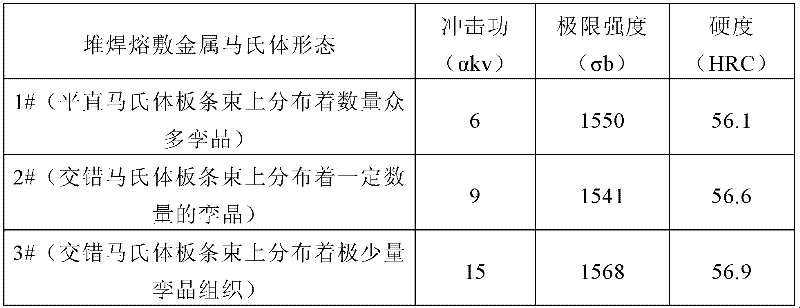

[0035] Embodiment 1 (technical scheme 1 of the present invention): every 1000 grams of drug core raw materials contain: chromium carbide: 90 grams, vanadium carbide: 20 grams, niobium carbide: 20 grams, vanadium iron: 30 grams, niobium iron: 54 grams, Chromium powder: 100 grams, nickel: 120 grams, molybdenum: 16 grams, 75 ferrosilicon: 21 grams, manganese: 50 grams, iron powder: 479 grams.

Embodiment 2

[0036] Embodiment 2 (technical scheme 2 of the present invention): every 1000 grams of drug core raw materials contain: chromium powder: 176 grams, vanadium carbide: 30 grams, niobium carbide: 60 grams, vanadium iron: 14 grams, nickel: 120 grams, molybdenum : 16 grams, 75 ferrosilicon: 21 grams, manganese: 50 grams, iron powder: 505 grams, graphite: 8 grams.

[0037] According to the formula of the comparative example and the embodiment, the powder of each component is mixed uniformly in the powder mixer; the steel strip is rolled into a U-shaped cross section on the wire rolling machine, and the mixed powder is added to the U-shaped groove of the steel strip. Then the U-shaped steel strip is rolled into a welding wire blank tube of Φ3mm~5mm; the welding wire blank tube is drawn to the finished size of Φ2.4mm~4.0mm by a multi-connected linear wire drawing machine, and then the standard layer is wound by a layer winding machine Roll around.

[0038] The surfacing flux-cored wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com