Solar groove type thermal power generation evacuated collector tube and preparation method thereof

A vacuum heat collecting tube and thermal power generation technology, which is applied in the field of thermal energy and power engineering, can solve the problems of reducing thermal stress, heat loss, and high temperature of connecting parts, and achieve the effects of reducing expansion stress, reducing temperature, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

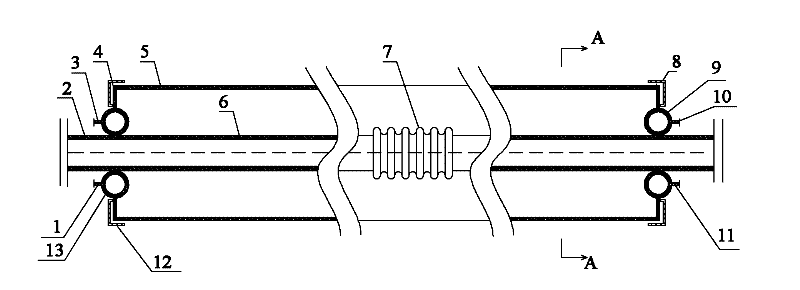

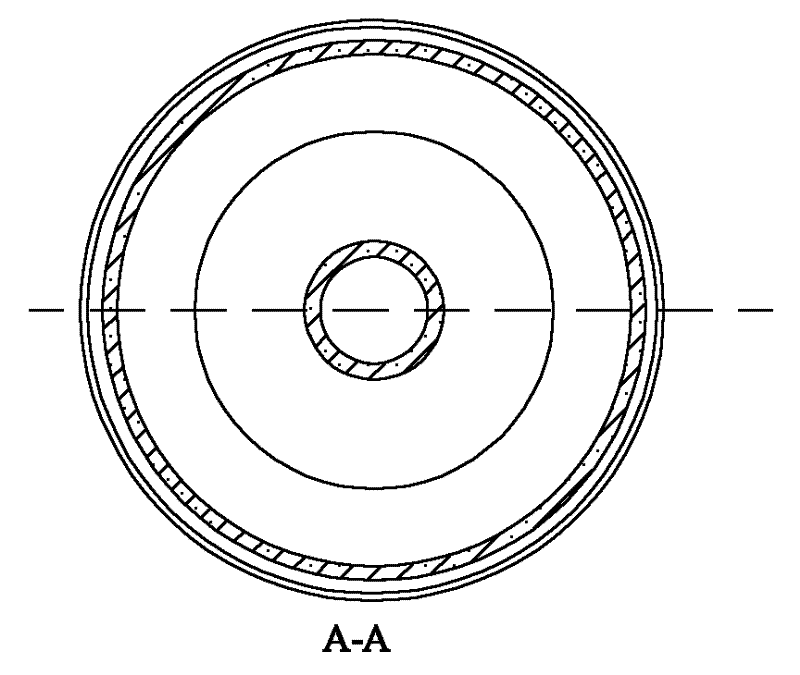

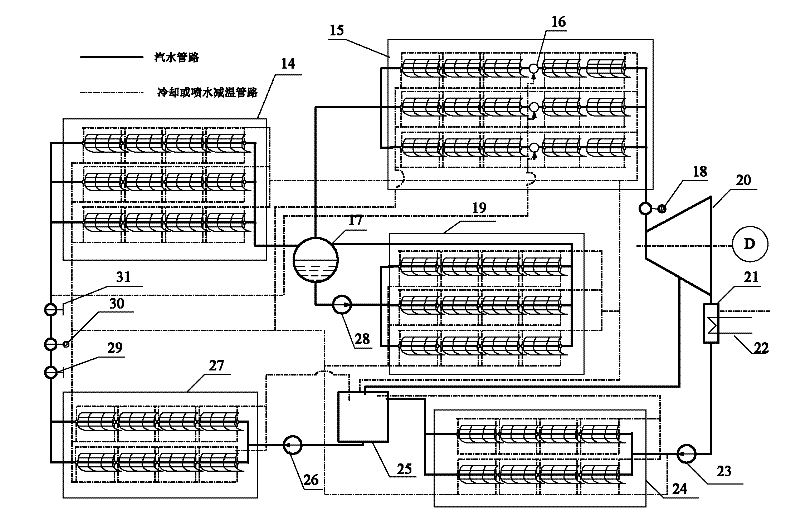

[0062] Such as figure 1 and 2 As shown, the solar trough heat collecting tube includes an inner tube 2 and an outer tube (5). It is characterized in that at the end of the heat collecting tube, an annular round tube is set between Kovar 40 and the inner tube 2, and the round tube is hollow. For example, an annular heat shield is provided on the outer surface of the Kovar alloy, and an expansion joint 7 is provided in the middle of the inner tube 2, and the expansion joint has a rectangular cross-section.

[0063] Kovar alloy 40 is made of 4j44 iron-nickel-cobalt low-expansion alloy with a thickness of 0.6-0.8mm and is welded by rings at right angles to each other. During annealing, the temperature is higher than the working temperature, ranging from 970-1050 degrees Celsius. Not less than 15 minutes.

[0064] The inner diameter of the cooling jacket of the heat collecting pipe is 1mm larger than the outer diameter of the heat collecting pipe, the diameter of the cooling jack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com