Poly-p-phenylene oxide (PPO) grated maleic anhydride as well as preparation method and application thereof

A technology of grafting maleic anhydride and maleic anhydride, which is applied in the field of plastics, can solve the problems of low grafting rate of PPO grafted maleic anhydride, poor compatibility, great harm to human body, etc. The effect of high branch rate and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

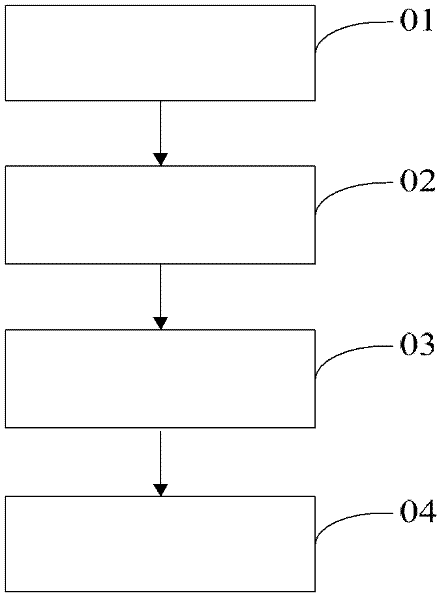

[0026] see figure 1 , figure 1 Show the embodiment of the present invention PPO grafted maleic anhydride preparation method flowchart, comprise the steps:

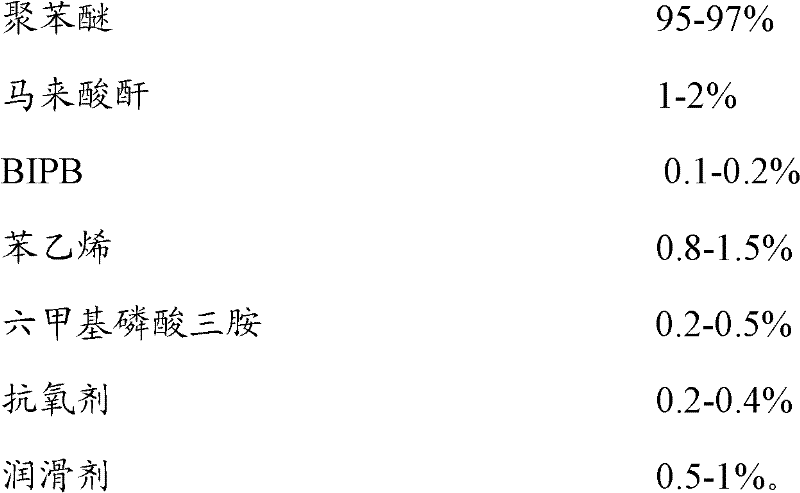

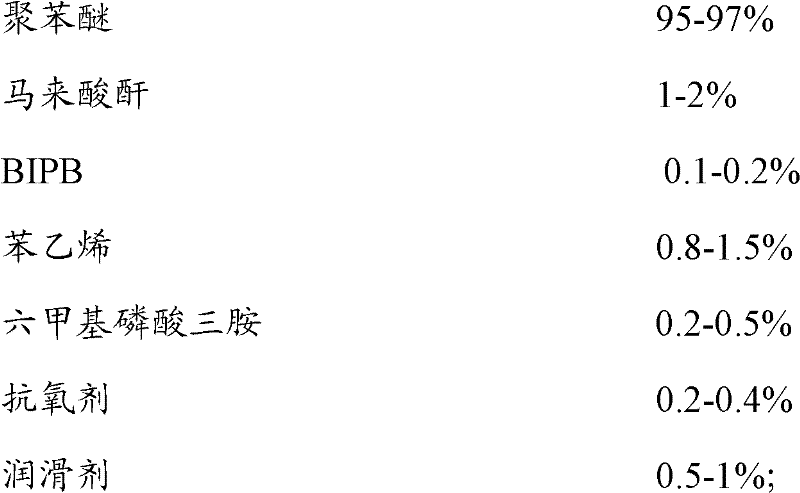

[0027] Step S01, respectively provide the following components in weight percentage:

[0028]

[0029] Step S02, mixing the BIPB and styrene to obtain a first mixture;

[0030] Step S03, mixing the first mixture, polyphenylene ether, maleic anhydride, hexamethyltriamine phosphate, antioxidant and lubricant to obtain a second mixture;

[0031] Step S04, extruding the second mixture to obtain PPO grafted maleic anhydride.

[0032] Specifically, in step S01,

[0033] The polyphenylene ether (PPO) is a linear polyphenylene ether, and the weight percentage of the polyphenylene ether is 95-97%; the polyphenylene ether can be selected as PPOPX 100L produced by Japan Asahi Kasei Company.

[0034] The maleic anhydride is a colorless needle crystal, and the weight percentage of the maleic anhydride is 1-2%; the maleic anhydr...

Embodiment 1

[0051] Adding styrene with a mass percentage of 1% into the reactor, adding 0.15% by weight of BIPB, and stirring for 10 minutes to obtain the first mixture;

[0052] The mass percentage composition is 96.25% PPO, the mass percentage composition is 1.2% maleic anhydride, the mass percentage composition is 0.4% hexamethyl phosphate triamine, the mass percentage composition is 0.2% 1010 and 0.1% 168 and 0.7% lubricant by mass percentage are poured into the reactor, and the previously prepared styrene / BIPB mixed solution is slowly added dropwise to the material, and stirred evenly to obtain the second mixture;

[0053] The second mixture is added into the hopper of the twin-screw extruder, grafted through melting reaction, extruded and granulated. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 210°C; zone 2: 220°C; zone 3: 230°C; zone 4: 240°C; machine head: 250°C; ~5min, the pressure is 14MPa.

Embodiment 2

[0055] Adding styrene with a mass percentage of 1% into the reactor, adding 0.15% by weight of BIPB, and stirring for 15 minutes to obtain the first mixture;

[0056] The mass percentage composition is 95.65% PPO, the mass percentage composition is 1.8% maleic anhydride, the mass percentage composition is 0.4% hexamethyl phosphate triamine, the mass percentage composition is 0.2% 1010 and 0.1% 168 and 0.7% lubricant by mass percentage are poured into the reactor, and the previously prepared styrene / BIPB mixed solution is slowly added dropwise to the material, and stirred evenly to obtain the second mixture;

[0057] The second mixture is added into the hopper of the twin-screw extruder, grafted through melting reaction, extruded and granulated. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 210°C; zone 2: 220°C; zone 3: 230°C; zone 4: 240°C; machine head: 250°C; ~5min, the pressure is 14MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com