Minim moisture detection system based on scanning method

A technology of detection system and scanning method, which is applied in the field of micro-water detection system and gas detection system based on scanning method, can solve the problems of water and liquid interference in key equipment, large gas consumption, fear of pollution, etc., and achieve the elimination of unstable effects, Short response times and wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

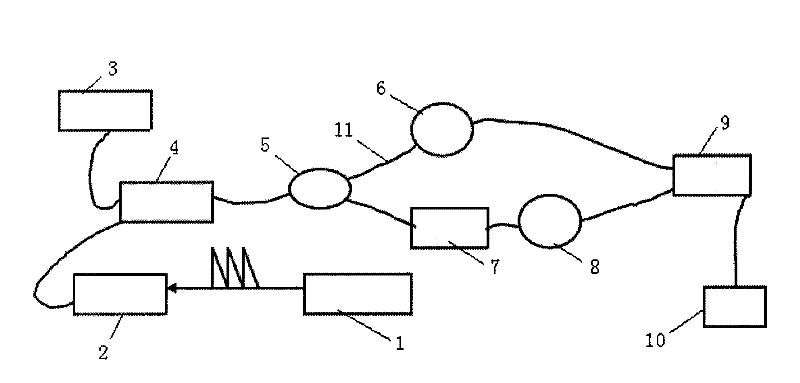

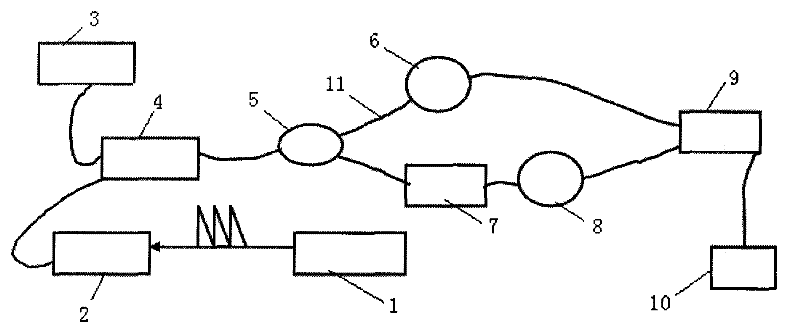

[0033] Embodiments of the present invention such as systems figure 1 Shown: including DFB laser 4, 1*2 coupler 5, gas chamber 7, photodetector 6, 8, data acquisition card 9, computer 10, sawtooth wave generation circuit 1, temperature control circuit 3 and current drive circuit 2, It is characterized in that the output end of the DFB laser 4 is connected to the 1*2 coupler 5 through its pigtail; the back of the 1*2 coupler 5 is respectively connected to two optical paths through ordinary optical fibers 11, one of which is a photodetector 6, and the other is a The gas chamber 7 is connected with the optical path of the photodetector 8 in series, and the output ends of the photodetectors 6 and 8 in the two optical paths are electrically connected to the data acquisition card 9 respectively, and the output end of the data acquisition card 9 is connected with the computer phase 10; sawtooth The wave generating circuit 1 is connected to the current drive circuit 2 and connected to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com