Wet silicon carbide sand for solar silicon chip wire cutting

A technology of solar silicon wafer and silicon carbide sand, which is applied in the direction of fine work equipment, stone processing equipment, manufacturing tools, etc., can solve the problems of unstable equipment efficiency, high production management and storage costs, and great influence of human factors. The effect of good quality stability, high cutting quality and low operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

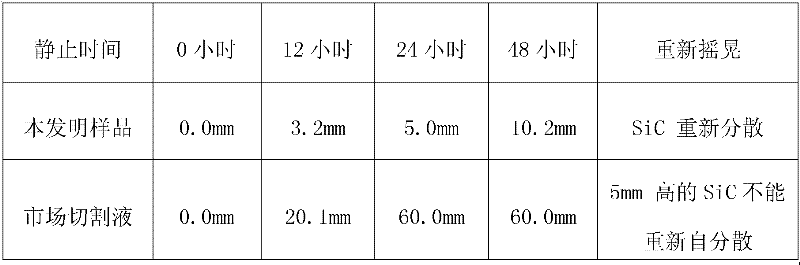

Image

Examples

Embodiment Construction

[0025] The wet silicon carbide sand material of the present invention is specifically set forth below by preparing 1000kg wire cutting mortar:

[0026] Weigh 530 kg of polyethylene glycol (PEG-200), 59 kg of nano film-forming agent, 18 kg of dispersant, 15 kg of surfactant, 5 kg of defoamer, 3 kg of metal corrosion inhibitor, GC15000 silicon carbide particles 1180 kg, of which: the nano-film-forming agent is a variety of hydrolyzable monomer multi-polymer copolymers with a molecular weight between 3,000 and 200,000; the dispersant is a styrene-acrylic monomer copolymer with a molecular weight of 2,000-20,000; And anionic or / and non-ionic, the surfactant is epoxy compound and acrylate complex, the defoamer is amino-modified methyl silicone oil emulsion, and the metal corrosion inhibitor is inorganic salt, nano-component The film agent is a variety of hydrolyzable monomer multi-polymer copolymers.

[0027] a. Add 530 kg of polyethylene glycol (PEG-200) into the special mixing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com