Thermal-insulation window film and preparation method thereof

A heat-insulating window film and plastic film technology, applied in chemical instruments and methods, film/sheet-shaped adhesives, adhesive additives, etc., can solve poor heat insulation effect, high light transmittance heat insulation performance, infrared The light barrier rate does not exceed 55%, to achieve good radiation and reduce radiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 prepares thermal insulation window film

[0036] The specific operation is as follows:

[0037] (A) Prepare raw materials

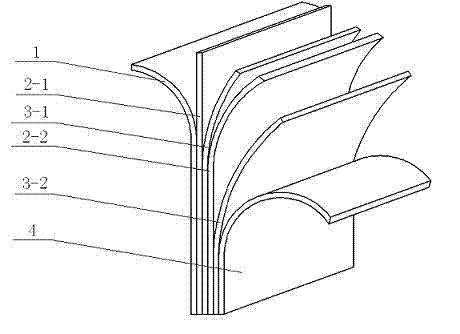

[0038] ① Prepare a transparent polyester plastic film substrate 2-1 with a thickness of 19 μm, a UV-blocking transparent polyester plastic film substrate 2-2 with a thickness of 12 μm, and a release film 4 with a thickness of 19 μm;

[0039] ②Prepare the mixed material to form the scratch-resistant and wear-resistant layer 1

[0040] Prepare the above-mentioned components according to the mass ratio of polyurethane: toluene: butanone: 5:3:7, wherein the polyurethane is M420 produced by Qidong Qingyun Fine Chemical Co., Ltd., and its solid content is 99.9%;

[0041] Mix the above components evenly at room temperature, then save for later use;

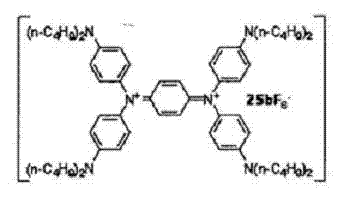

[0042] ③Prepare the mixture to form heat-insulating acrylic adhesive layer 3-1

[0043] According to heat insulation material: acrylic adhesive: curing agent: ultraviolet light absorber: dyestu...

Embodiment 2

[0054] Embodiment 2 prepares thermal insulation window film

[0055] The specific operation is as follows:

[0056] (A) Prepare raw materials

[0057] ① Prepare a transparent polyethylene plastic film substrate 2-1 with a thickness of 19 μm, a UV-blocking transparent polyethylene plastic film substrate 2-2 with a thickness of 12 μm, and a release film 4 with a thickness of 23 μm;

[0058] ②Prepare the mixed material to form the scratch-resistant and wear-resistant layer 1

[0059] Prepare the above-mentioned components according to the mass ratio of polyurethane: toluene: butanone: 10:13:10, wherein the polyurethane is M420 produced by Qidong Qingyun Fine Chemical Co., Ltd., and its solid content is 99.9%;

[0060] Mix the above components evenly at room temperature, then save for later use;

[0061] ③Prepare the mixture to form heat-insulating acrylic adhesive layer 3-1

[0062] According to heat insulation material: acrylic adhesive: curing agent: ultraviolet light absor...

Embodiment 3

[0072] Embodiment 3 prepares thermal insulation window film

[0073] (A) Prepare raw materials

[0074] ① Prepare a transparent polyester plastic film substrate 2-1 with a thickness of 23 μm, a UV-blocking transparent polyester plastic film substrate 2-2 with a thickness of 19 μm, and a release film 4 with a thickness of 23 μm;

[0075] ②Prepare the mixed material to form the scratch-resistant and wear-resistant layer 1

[0076] Prepare the above-mentioned components according to the mass ratio of polyurethane: toluene: butanone: 20:15:18, wherein the polyurethane is M420 produced by Qidong Qingyun Fine Chemical Co., Ltd., and its solid content is 99.9%;

[0077] Mix the above components evenly at room temperature, then save for later use;

[0078] ③Prepare the mixture to form heat-insulating acrylic adhesive layer 3-1

[0079] According to heat insulation material: acrylic adhesive: curing agent: ultraviolet light absorber: dye: methyl ethyl ketone: toluene mass ratio is 3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com