Fluoride removing technology for wastewater discharged from polysilicon solar photovoltaic cell productions

A technology for producing wastewater and sunlight, which is applied in the fields of energy wastewater treatment, water pollutants, water/sewage multi-stage treatment, etc. Quantity instability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

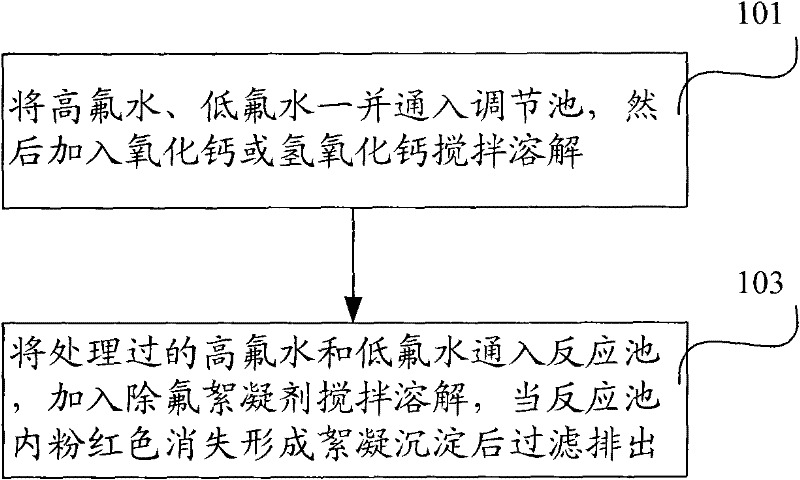

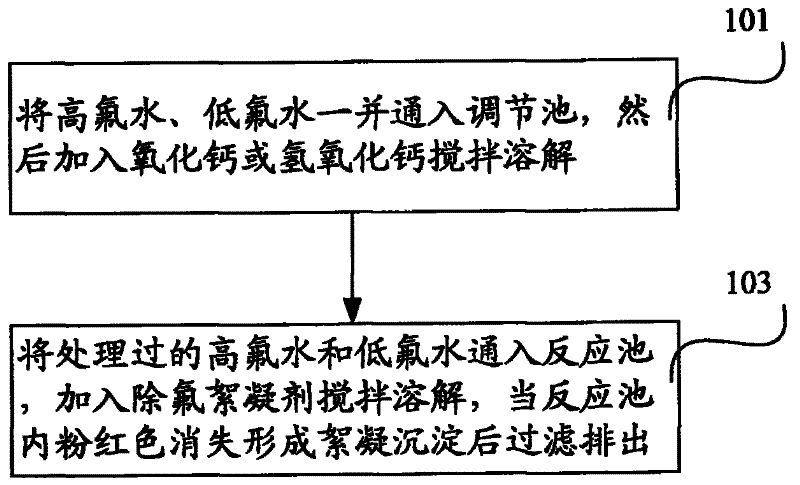

[0025] figure 1 It is a structural schematic diagram of an embodiment of a process for removing fluorine from polycrystalline silicon solar photovoltaic cell production wastewater of the present invention, as figure 1 shown, including:

[0026] Step 101, pass high-fluorine water and low-fluorine water into the adjustment tank together, and then add calcium oxide or calcium hydroxide to stir and dissolve, so that the pH value of the water in the adjustment tank is 7. After flocculation and precipitation, take its supernatant and enter reaction pool. Among them, in this embodiment, the high-fluorine water is directly passed into the adjustment tank to remove fluorine together with the low-fluorine water without pretreatment, which simplifies the treatment process; at the same time, calcium oxide or Ca(OH) 2 Substitute carbide slag or lime, in the F - At the same time of preliminary removal, the generation of toxic and harmful acetylene gas is avoided, and secondary pollution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com