Plant non-toxic adhesive used for indoor decoration and preparation method thereof

A technology for interior decoration and adhesives, applied in the direction of monocarboxylic acid ester copolymer adhesives, unsaturated alcohol copolymer adhesives, adhesive types, etc., can solve the problems of high production cost and complicated preparation process, and achieve Low production cost, simple preparation process, and improved water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

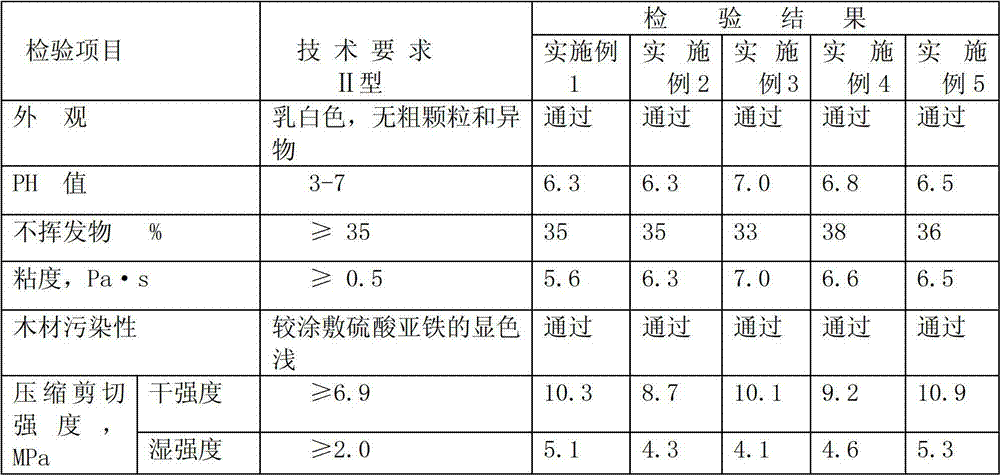

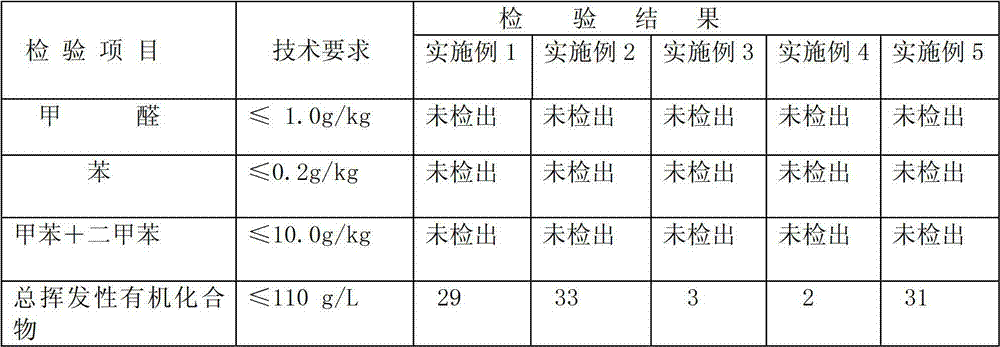

Examples

Embodiment 1

[0032] Adhesive formulation:

[0033] Modified starch glue with a solid content of 20% 60Kg, polyvinyl alcohol 2Kg, ethylene glycol 0.2Kg, vinyl acetate-ethylene copolymer emulsion (ethylene content 14-18%, w / w) 30Kg, rosin solution 3Kg, calcium carbonate 10Kg , water 10Kg, Tween-800.2Kg.

[0034] Preparation:

[0035] 1) Preparation of modified starch glue: Mix 10Kg of oxidized tapioca starch and 90Kg of pregelatinized tapioca starch, add to 40°C water under stirring, adjust the pH value to 5 with citric acid, raise the temperature to 55°C, and keep it warm for 30 minutes. Solid content is the modified starch glue of 20%, takes out 60Kg for subsequent use;

[0036] The preparation of rosin solution: take the ethanol that volume concentration is 100% as solvent, add rosin powder to make saturated solution, take out 3Kg saturated solution for subsequent use;

[0037] 2) Put polyvinyl alcohol in water, raise the temperature to 90°C to completely dissolve the polyvinyl alcohol...

Embodiment 2

[0041] Adhesive formulation:

[0042] Modified starch glue with a solid content of 25% 50Kg, polyvinyl alcohol 6Kg, ethylene glycol 0.3Kg, vinyl acetate-ethylene copolymer emulsion (ethylene content 14-18%, w / w) 15Kg, rosin solution 2Kg, calcium carbonate 8Kg , water 30Kg, Tween-800.4Kg, n-butanol 0.3Kg.

[0043] Preparation:

[0044] 1) Prepare modified starch glue: Mix 30Kg of oxidized tapioca starch and 70Kg of pregelatinized tapioca starch, add to 35°C water under stirring, adjust the pH value to 6 with hydrochloric acid, raise the temperature to 75°C, and keep it warm for 20 minutes. Content is the modified starch glue of 25%, takes out 50Kg for subsequent use;

[0045] Preparation of rosin solution: take ethanol with a volume concentration of 98% as a solvent, add rosin powder to make a saturated solution, and take out 2Kg of the saturated solution for subsequent use;

[0046] 2) Put polyvinyl alcohol in water, raise the temperature to 95°C to dissolve the polyvinyl a...

Embodiment 3

[0050] Adhesive formulation:

[0051] Modified starch glue with a solid content of 20% 75Kg, polyvinyl alcohol 4Kg, ethylene glycol 0.4Kg, vinyl acetate-ethylene copolymer emulsion (ethylene content 14-18%, w / w) 10Kg, rosin solution 4Kg, calcium carbonate 3Kg, water 20Kg, Tween-800.5Kg, sodium benzoate 0.08Kg.

[0052] Preparation:

[0053] 1) Prepare modified starch glue: Mix 25Kg of oxidized tapioca starch and 75Kg of pregelatinized tapioca starch, add to 45°C water under stirring, adjust the pH value to 7 with hydrochloric acid, raise the temperature to 70°C, and keep it warm for 25 minutes. Content is the modified starch glue of 20%, takes out 75Kg for subsequent use;

[0054] The preparation of rosin solution: take the ethanol that volume concentration is 95% as solvent, add rosin powder and make saturated solution, take out 4Kg saturated solution for subsequent use;

[0055] 2) Put polyvinyl alcohol in water, raise the temperature to 93°C to completely dissolve the po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com