Hearth negative pressure control method and system for coal-fired generating unit draught fan driven by small steam turbine

A technology for generating set and furnace negative pressure, applied in the field of control systems, can solve the problems of low starting current electric bus voltage, affecting the safety of operating equipment, and difficulty in design of plant power consumption, so as to improve efficiency, reduce plant power consumption rate, and avoid effect of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

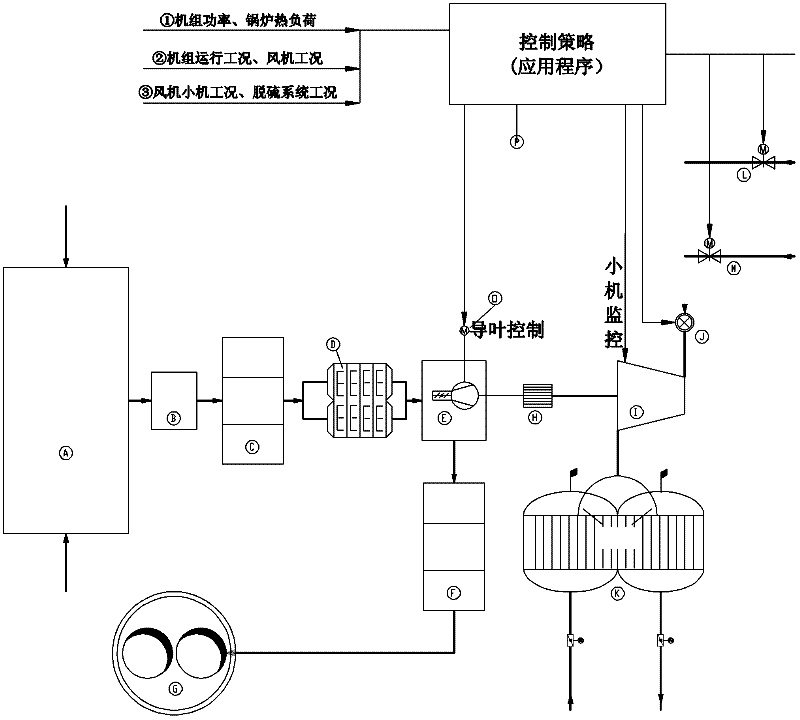

[0056] figure 1 It is a schematic diagram of the composition and connection relationship of the furnace negative pressure control system driven by a small induced draft fan (also called a small machine) of the present invention.

[0057] figure 1 illustrate:

[0058] A- Boiler furnace is the main component of boiler equipment for coal-fired power generating units. Inside the furnace, boiler pulverized coal (fuel oil) is burned, and the heating surface of the boiler absorbs heat to heat the furnace water and steam.

[0059] B- Boiler off-loading device, which is used to remove nitrogen compounds in the smoke and improve the emission index of flue gas pollutants.

[0060] C-Air Preheater - This device is used to use the flue gas discharged from the boiler to heat the air that will be fed into the furnace for combustion, so as to improve the thermal efficiency of the boiler.

[0061] D-Electric precipitator, the device is used to remove the soot in the boiler flue gas, and i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com