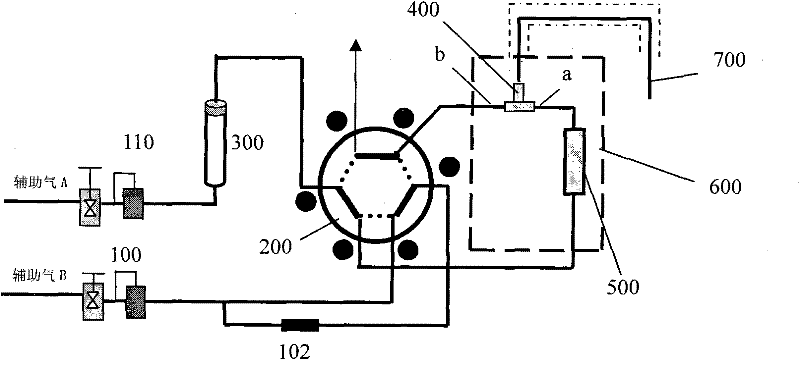

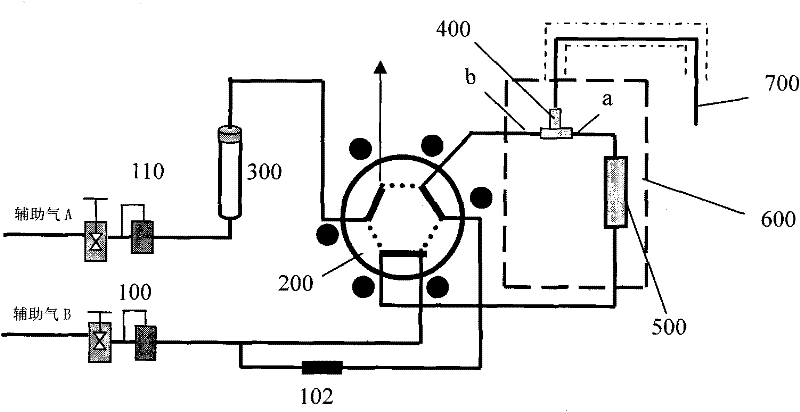

Purging and trapping thermal desorption device

A technology of purging and trapping and thermal analysis, which is applied in measurement devices, analytical materials, instruments, etc., can solve the problem of high equipment cost, and achieve the effects of small size, reduced power consumption, and reduced heating power.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

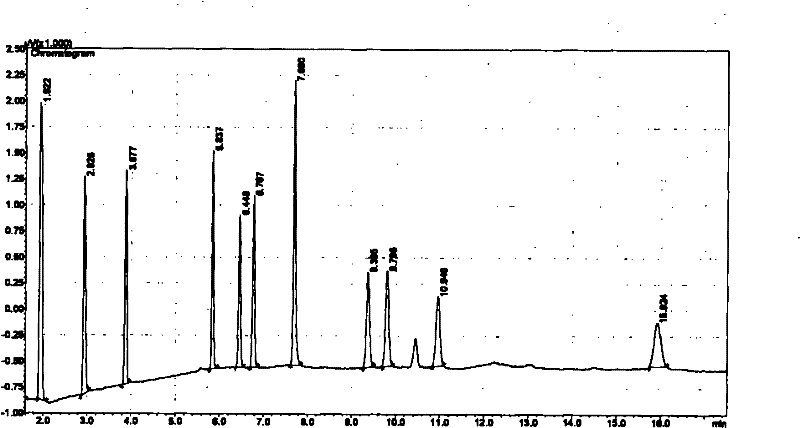

[0034] Take and add C 2 ~C 4 Put 25mL of the water sample of the VOC standard sample in the purge bottle 300, adjust (110) to make the purge gas flow rate at 60mL / min, adjust (100) flow rate at 5mL / min, and purge for 6min. The adsorption column is OV-1+Tenax+carbon molecular sieve, the thermal analysis temperature is 290°C, and the external heat temperature of the transfer tube is 200°C. It is analyzed by Agilent 6890Plus, and the analysis spectrum is as follows figure 2 shown.

[0035] components

Embodiment 2

[0037] Utilizing the device of the present invention, a clustered capillary extraction column coated with polymethylsiloxane is used as an adsorption column to directly extract trace amounts of polycyclic aromatic hydrocarbons and other organic pollutants in water. Six polycyclic aromatic hydrocarbons, naphthalene, acenaphthene, fluorene, phenanthrene, anthracene, and fluoranthene, were used to prepare 200 mL of each standard sample containing 20 μg / L water. The sample purge pool was replaced with a pneumatic sample bottle that directly feeds the water sample. The desorption temperature of the extraction column was 280°C, and the jacket of the transfer tube was heated at 210°C. Analyzed with Agilent 6890Plus, the analysis spectrum is as follows image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com