Surface mounted type power light-emitting diode (LED) bracket manufacturing method and product manufactured thereby

An LED bracket and surface mount technology, applied in electrical components, circuits, semiconductor devices, etc., to achieve high heat resistance requirements, strong popularity, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

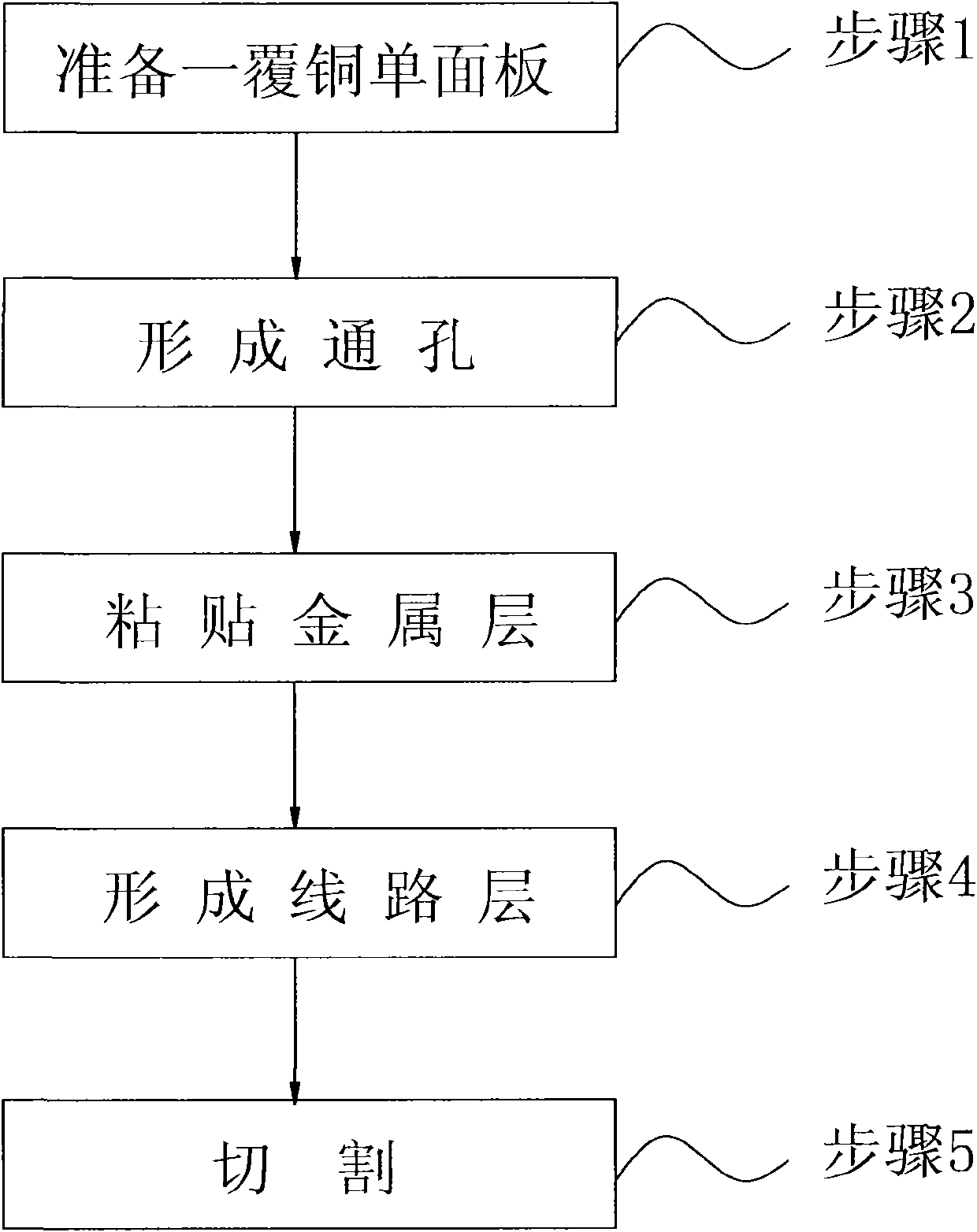

[0035] image 3 The flow chart of the manufacturing method of the surface mount type power LED bracket unit of the present invention is given, and the following is combined with the attached image 3 Be specific.

[0036] Such as image 3 As shown, the manufacturing method of the surface mount type power LED bracket and its unit is as follows: step 1) preparing a single copper clad PCB; through holes; step 3) covering a metal sheet on the lower surface of the copper-clad PCB single-sided board with an adhesive material, and sealing the bottom of the through-hole; step 4) in the copper-clad PCB single-sided board Forming the circuit layer 1 on the layer, forming the circuit layer 2 on the metal sheet; 5) cutting the LED bracket to split into independent LED bracket units.

[0037] In step 1), the copper-clad PCB single-sided insulating board is composed of a copper layer and a PCB insulating flat plate carrying the copper layer. In order for the LED device to withstand the ...

Embodiment 2

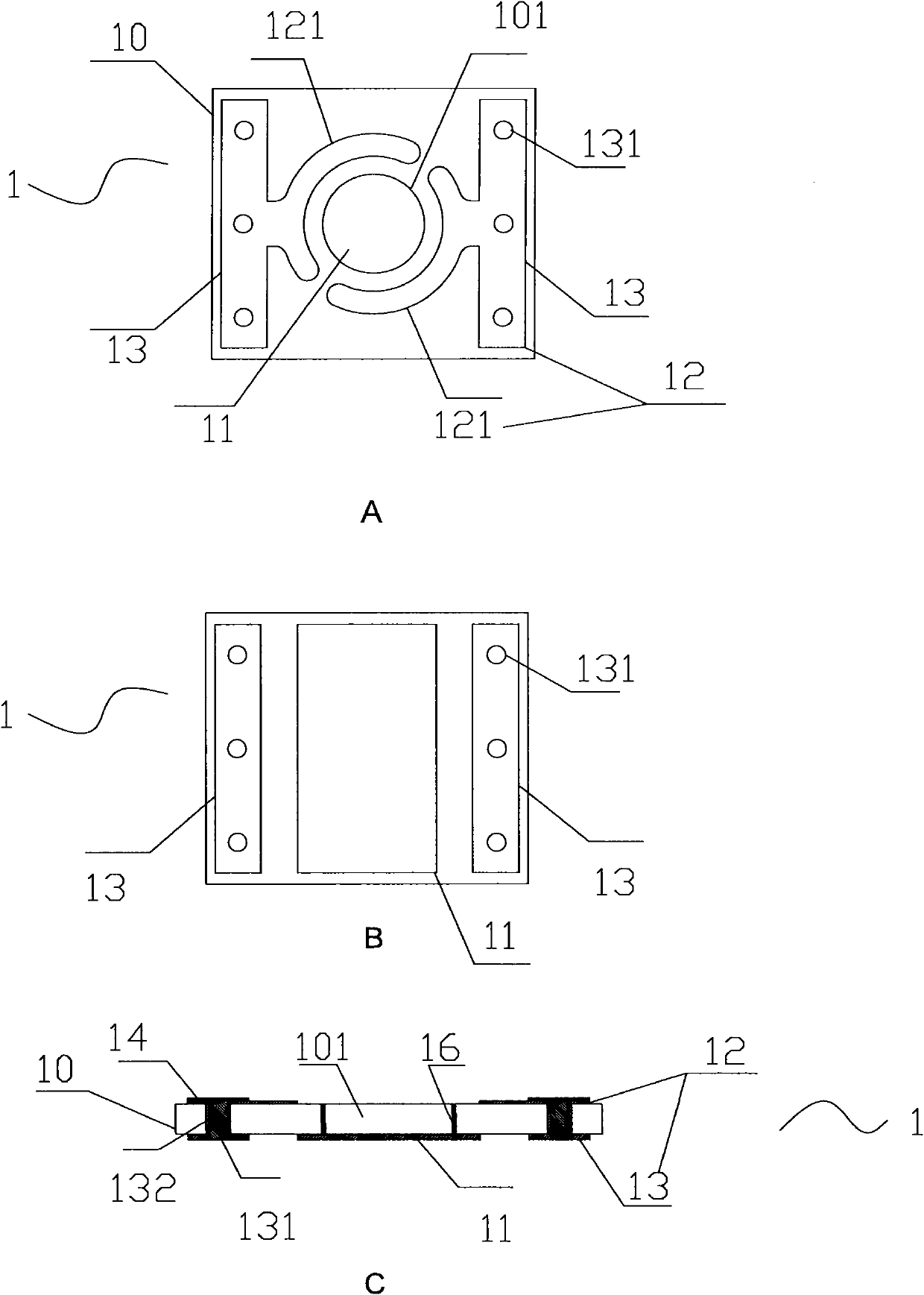

[0050] Figure 4 An embodiment of a surface-mounted power LED bracket unit of the present invention is given, and its structure is now combined with the attached Figure 4 Be specific.

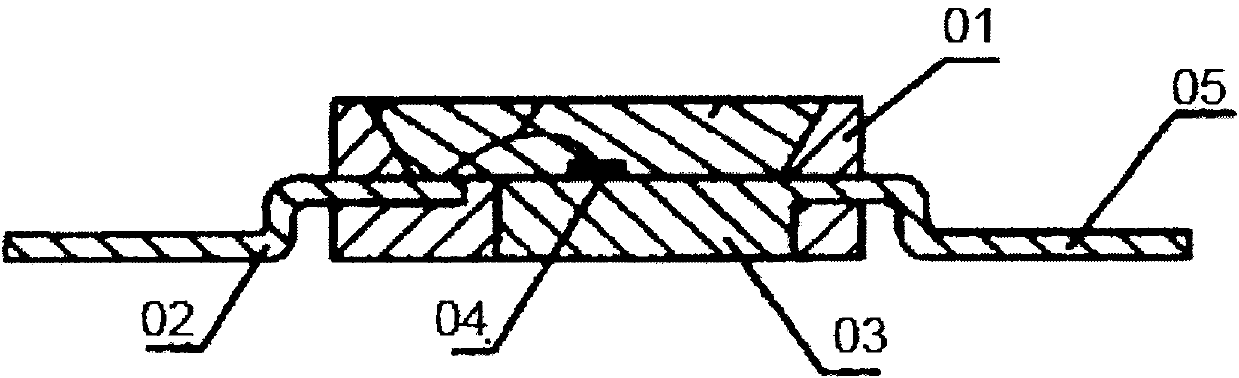

[0051] Such as Figure 4 As shown, a surface mount type power LED bracket unit 1, Figure 4 Shown in A is a schematic diagram of the upper surface structure of the support unit, Figure 4 B shows the schematic diagram of its lower surface structure, Figure 4 C shows its cross-sectional view, and the structure of the illustrated LED bracket unit includes: a copper-clad PCB single-sided board with a through hole 101, wherein the copper-clad PCB single-sided board is made of a copper circuit layer 12 and carries the An ordinary PCB insulating plate 10 with a copper layer is composed of a chip placement portion 11 arranged on the lower surface of the insulating plate 10 and sealing the bottom of the through hole 101 , and a circuit layer 12 arranged on the insulating plate 10 . Wherein, the ...

Embodiment 3

[0056] Figure 5 Another specific embodiment of a surface-mounted power LED bracket unit 1 of the present invention is given. Attached below Figure 5 Describe its structure in detail.

[0057] The difference between the present embodiment three and the preceding embodiment two lies in the structure of the positive and negative electrodes 13: as attached Figure 5 As shown, the positive or negative electrode 13 is composed of at least one small through hole 131 penetrating the insulating plate 10 and the circuit layer 12 and a conductive material 133 filling the small through hole 131 . Wherein, the conductive material 133 is electrically connected to the circuit layer 12 . Among them, the preferred number of small through holes is three, and the conductive material 133 is preferably silver paste

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com