System and process for desulfuration and denitration by pure oxygen dielectric barrier discharge in flue

A dielectric barrier discharge, desulfurization and denitrification technology, applied in the direction of dispersed particle separation, chemical instruments and methods, separation methods, etc., can solve the problems of high operating cost, unfavorable renovation of old power plants, large amount of operation and maintenance, etc., and achieve simplified desulfurization and denitrification equipment and technological process, realizing green recycling and increasing economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

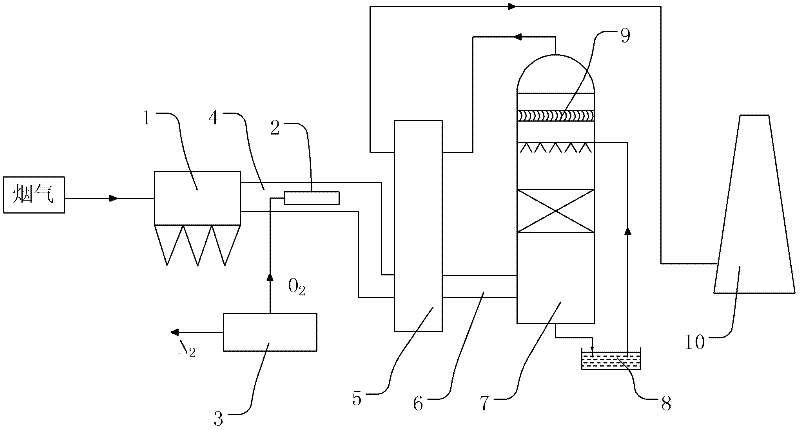

[0057] Implementation case 1: as attached figure 1 As shown, the dielectric barrier discharge reactor is placed in the flue after the electrostatic precipitator, and the reactors are evenly arranged in the flue according to the load of different units, the number of dielectric barrier discharge reactor monomers and the flow rate of oxygen passing through the reactor. , so that the sprayed oxidizing gas can fully mix and react with the flue gas. The lye in the absorption tower adopts NaOH, KOH, Na 2 CO 3 , Ca(OH) 2 , CaCO 3 One or a mixture of several of them.

Embodiment example 2

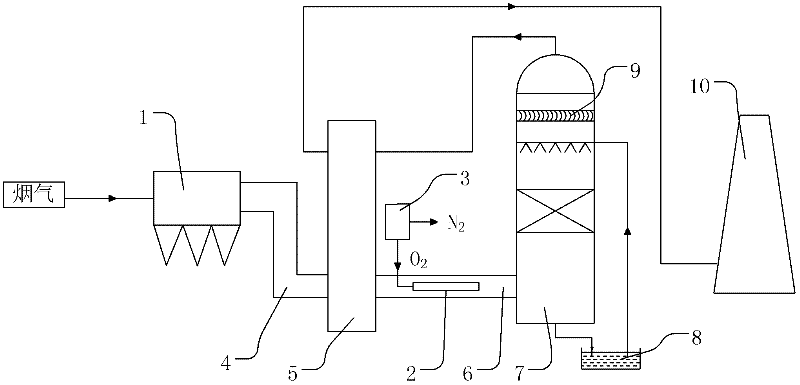

[0058] Implementation case two: as attached figure 2 As shown, the dielectric barrier discharge reactor is placed in the exhaust duct between the gas-gas heater and the inlet of the lye absorption tower, and the reduction of the flue gas temperature is conducive to the oxidation of NO. The number of dielectric barrier discharge reactor monomers and the flow rate of oxygen passing through the reactor are selected according to the different loads of the unit. The reactors are evenly arranged in the flue, so that the oxidizing gas ejected can fully mix and react with the flue gas. The lye in the absorption tower adopts NaOH, KOH, Na 2 CO 3 , Ca(OH) 2 , CaCO 3 One or a mixture of several of them.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com