Method for bionic coupling of strengthened and toughened mechanical parts

A technology of mechanical parts and components, applied in the field of bionic coupling toughened mechanical parts, can solve the problems of increased service life, inability to achieve optimization degree, controllability of optimization direction, expensive price, etc., to prolong service life , The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

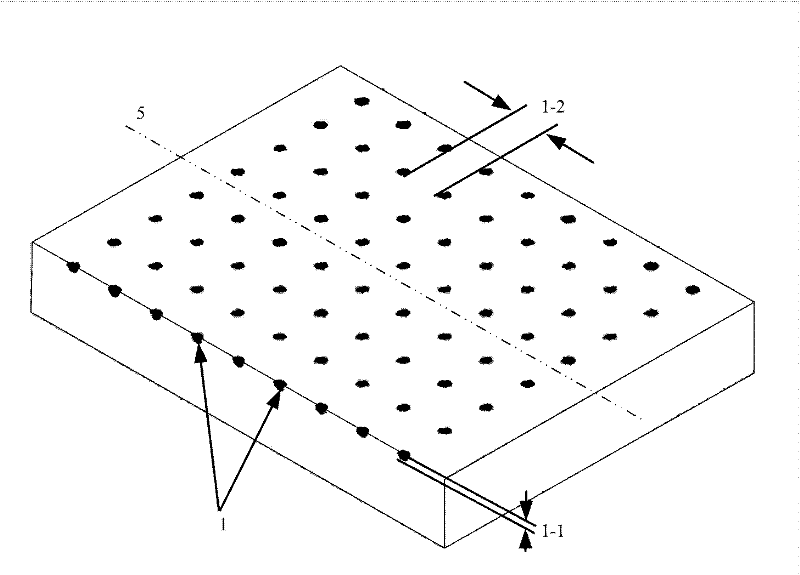

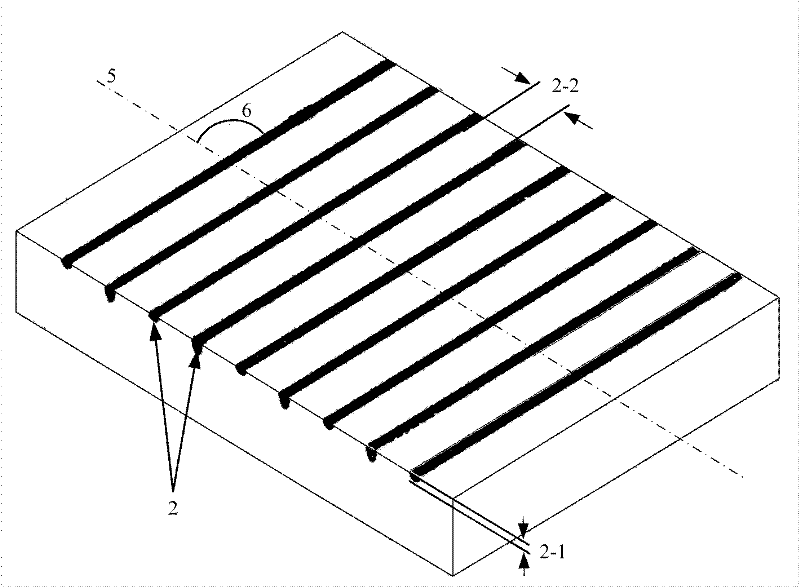

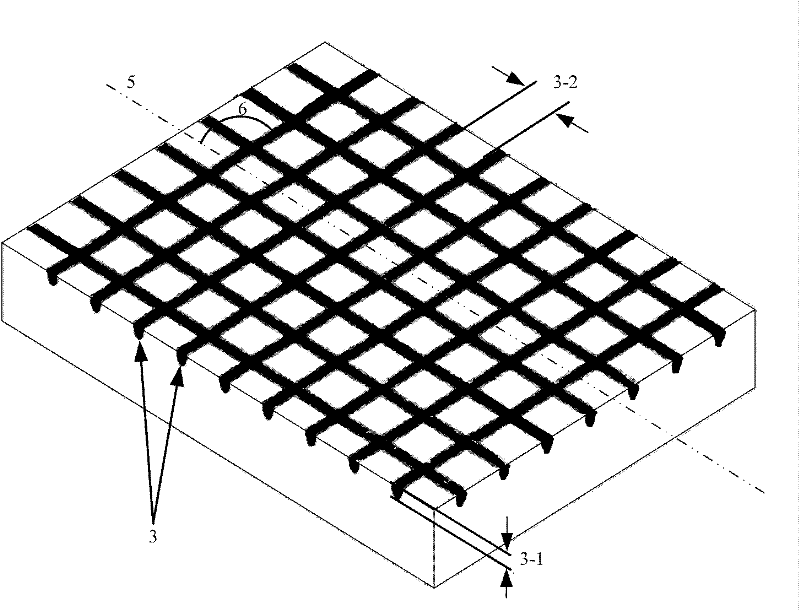

[0043] The specific method is to first design the peg-shaped, dam-shaped, grid-shaped or layered one-dimensional bionic topography coupled element or peg-shaped coupled embankment-shaped, peg-shaped coupled grid-shaped, peg-shaped coupled layered shape on the surface of the material. , dam-like coupled layered, grid-like coupled layered binary bionic topography coupling element; after selecting the preparation method of strengthening the organization coupling element, use sandpaper to pretreat the surface of the parts, clean the surface of the parts, make the parts The surface obtains uniform and stable energy absorption during electric pulse or laser treatment, and prevents the fusion of harmful elements such as hydrogen, sulfur, and phosphorus during high-energy beam treatment; for parts that choose high-energy beam combined with cladding or fusion welding The surface of the part is cleaned with sandpaper and the alloy powder or welding wire is fixed with water glass; after t...

Embodiment 1

[0054] Example 1. Strengthening and toughening effect of binary bionic coupling toughening mode

[0055]

[0056]

[0057]

[0058]

Embodiment 2

[0059] Example 2 Strengthening and toughening effect of multiple bionic coupling strengthening and toughening modes

[0060]

[0061]

[0062]

[0063]

[0064]

[0065]

[0066]

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Spacing | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com