Large-diameter hydrogen storage alloy tank and manufacturing method thereof

A hydrogen storage alloy, large-diameter technology, used in fixed-capacity gas storage tanks, gas/liquid distribution and storage, pressure vessels, etc. problems such as the service life of hydrogen alloys, to avoid hardening and local stress concentration, improve safety and reliability, and achieve high safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

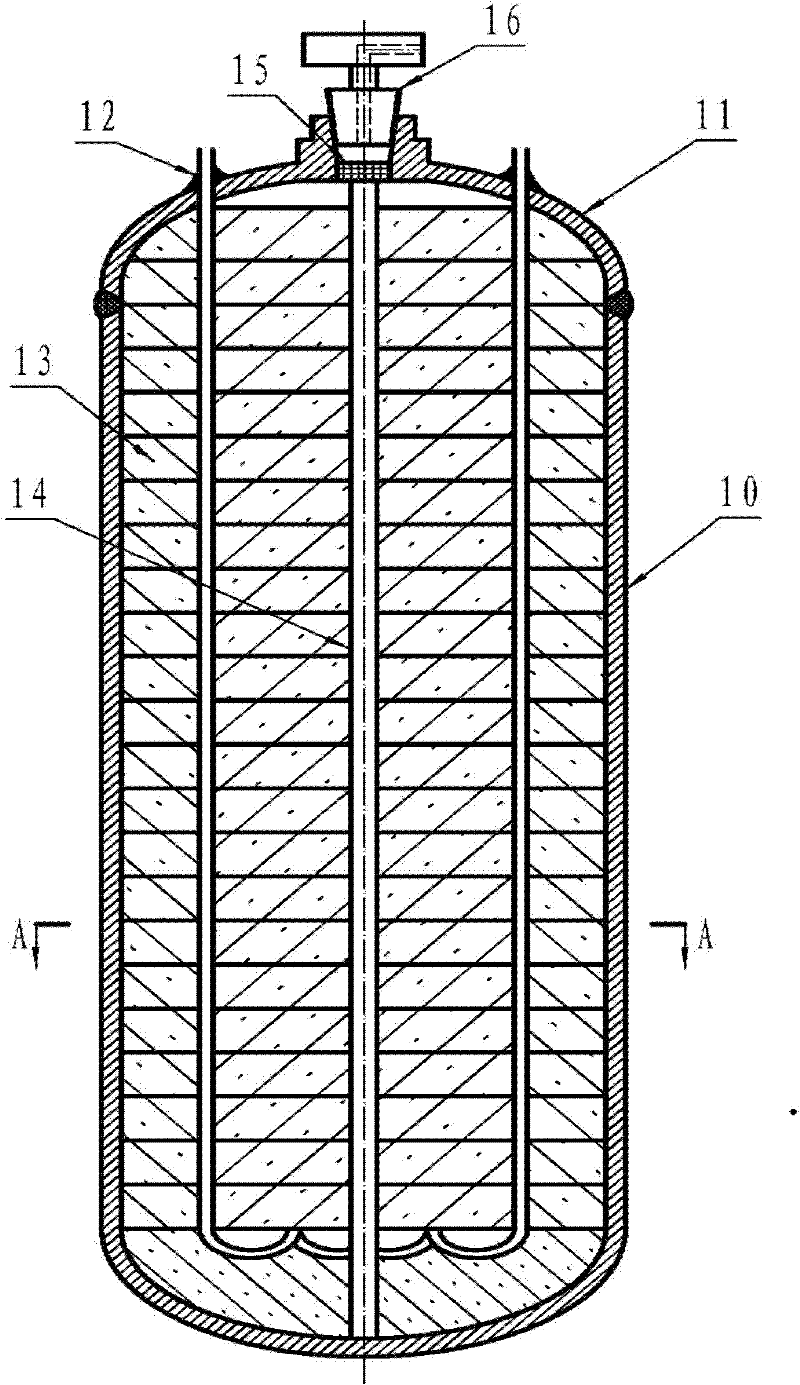

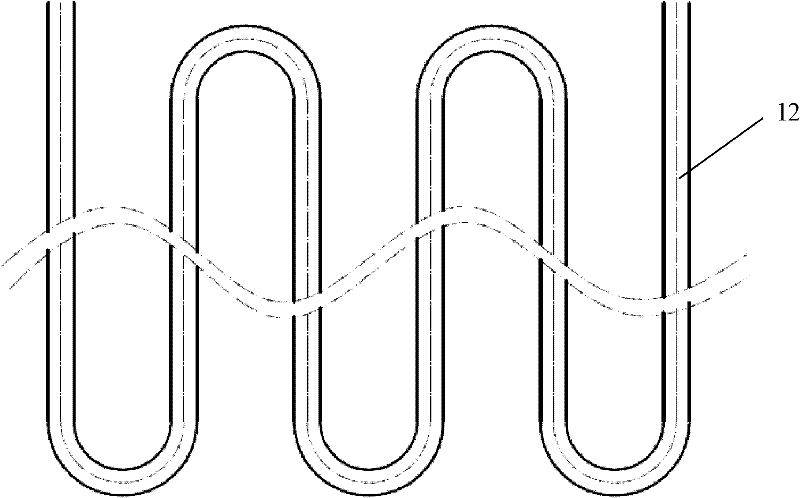

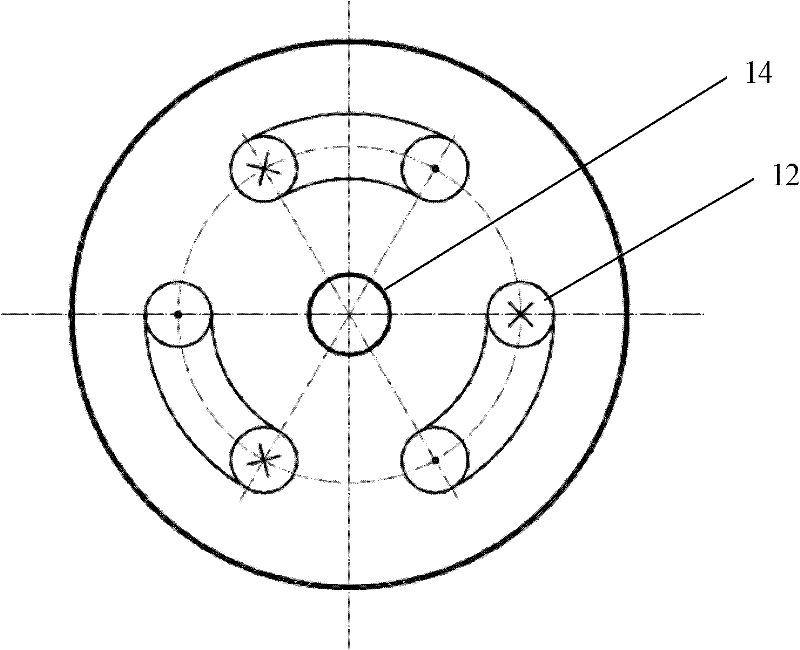

[0039] figure 1 Shown is an embodiment of the present invention—a schematic cross-sectional view of a large-diameter hydrogen storage alloy tank. It includes: steel cylinder cylinder (also called straight steel cylinder) 10, upper head 11, heat exchanger 12, annular porous mass transfer module 13, air duct 14, metal filter 15 and high pressure and high vacuum valve 16 . The steel cylinder body 10 is a high-strength seamless steel pipe formed by spinning, with an outer diameter of Φ480mm and a length of 3000mm; parallel pipes, such as figure 2 shown; and wound into an annular structure concentric with the cross-section circle of the cylinder body, placed in the cylinder body 10, as image 3 as shown, image 3 is the cross-section of the large-diameter hydrogen storage alloy tank, in image 3 Among them, the heat exchanger 12 is bent into 6 pipes, and the 6 pipes of the heat exchanger 12 are evenly distributed on a concentric arc with the cross section of the steel cylinde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com