Electrostatic image developing toner

An electrostatic image development and toner technology, which is applied in the direction of developer, electrography, instrument, etc., can solve the problems of easy cracking, peeling and brittleness of the fixed image, and achieve excellent heat resistance, stain resistance and crease Fixing property, good heat-resistant storage, high fastness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0166] In the reaction container equipped with stirring device, temperature sensor, cooling pipe, nitrogen introduction device, add 8 mass parts of sodium lauryl sulfate and 3000 mass parts of ion-exchanged water, stir with the stirring speed of 230rpm under nitrogen flow, simultaneously will The temperature rose to 80°C. After temperature rise, the polymerization initiator solution which melt|dissolved 10 mass parts of potassium persulfates in 200 mass parts of ion-exchanged water was added, and liquid temperature was adjusted to 80 degreeC.

[0167] Then, a polymerizable monomer mixture composed of the following substances was added dropwise to the reaction vessel within 1 hour, and then heated at 80° C. for 2 hours, stirred and polymerized to prepare a dispersion of resin fine particles (1H).

[0168]

[0169] A solution prepared by dissolving 7 parts by mass of polyoxyethylene (2) sodium lauryl ether sulfate in 800 parts by mass of ion-exchanged water was added to a rea...

preparation example 2

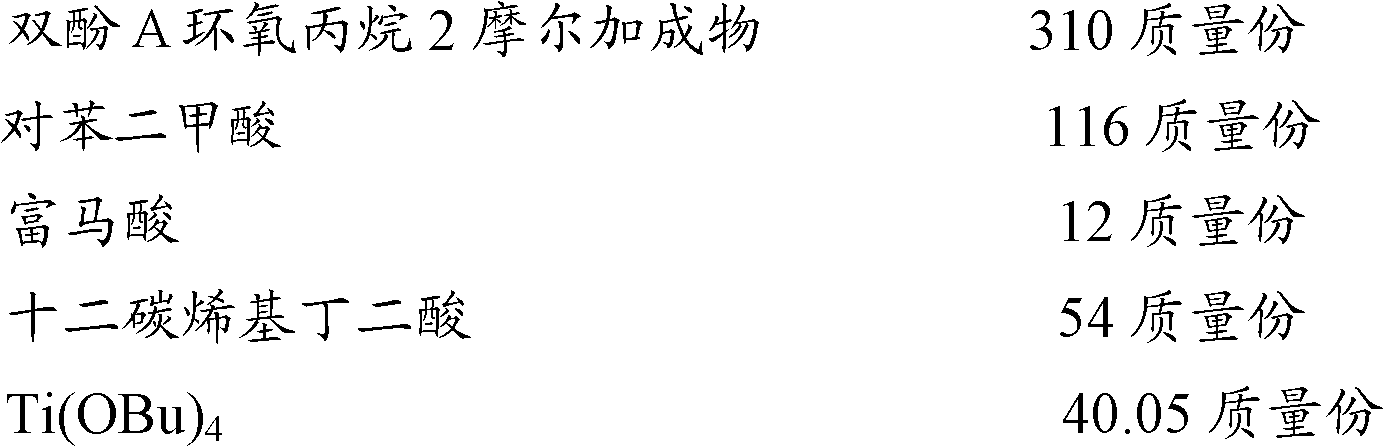

[0179] The following raw materials were added to the heat-dried three-necked flask, and then refluxed at 180° C. for 5 hours by mechanical stirring in an inert gas atmosphere of nitrogen. Then, the water generated in the reaction system was removed by distillation under reduced pressure, and the temperature was raised to 240°C. The dehydration condensation reaction was continued at 240° C. for 3 hours, and then the molecular weight was measured by GPC (gel permeation chromatography). When the weight average molecular weight was 27,000, the vacuum distillation was stopped to obtain a polyester resin.

[0180]

[0181] Then, 100 parts by mass of the above-mentioned polyester resin, 50 parts by mass of ethyl acetate, 25 parts by mass of isopropanol and 5 parts by mass of 10% ammonia solution were added to a separable flask, mixed and dissolved, and heated at 40° C. While heating and stirring, ion-exchanged water was added dropwise through a liquid-feeding pump at a liquid-feed...

preparation example 2~17

[0201] According to the formula in the following Table 1, except for changing the type and / or addition amount of the added components, the others are the same as the preparation example 1 of the dispersion liquid of the domain resin particles, and the domain resin particles [B-2] to [B-2] are respectively prepared. -17] latex [LxB2] ~ [LxB17].

[0202] The glass transition temperature, volume-based median diameter, and toluene-insoluble content of the domain resin particles [B2] to [B17] in the obtained latexes [LxB2] to [LxB17] can be measured by the methods described above. The results are shown in Table 1.

[0203] [Preparation Examples 1 to 4 of Dispersion Liquid of Comparative Domain Resin Microparticles]

[0204] According to the recipe in the following Table 1, except for changing the type and / or addition amount of the added components, the others are the same as the preparation example 1 of the dispersion liquid of the domain resin particles, respectively preparing do...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Median particle size | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com