Microwave-assisted natural volcanic scoria-sodium alginate composite microsphere water purification material

A technology of sodium alginate and composite microspheres, applied in the field of environmental engineering, can solve the problems of poor adsorption efficiency, easy to break, high water content, etc., and achieve the effect of fast and simple preparation process, stable structure and performance, and easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

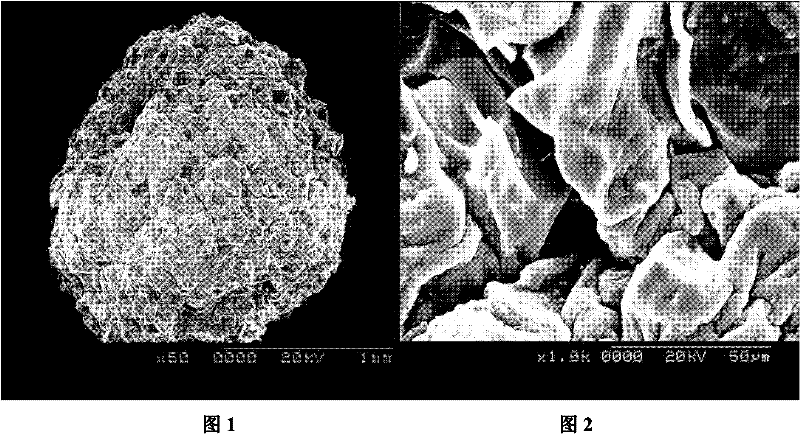

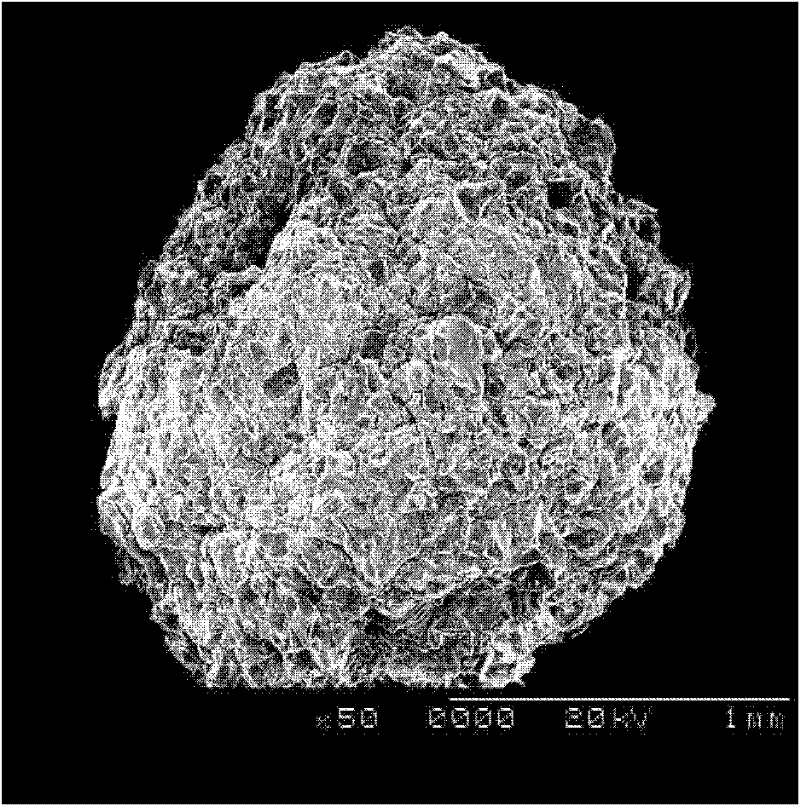

Image

Examples

Embodiment 1

[0020] (1) Natural volcanic slag pretreatment process:

[0021] Weigh 0.5 kg of natural volcanic slag, place it in deionized water, shake and wash it thoroughly, drain it, and dry it in an electric drying oven at 100°C for 5 hours, then mechanically crush it, and pass it through a 200-mesh sieve for later use.

[0022] (2) Prepare 1.5% sodium alginate solution (mass percentage):

[0023] Add 500mL of deionized water into the glass beaker in advance, then place it on an electric stirrer, quickly pour 7.5g of sodium alginate solid weighed under the condition of heating at 50°C, and stir fully at a speed of 500r / min until the solution is clear Transparent, then use 100% power to sonicate for 3 minutes to remove air bubbles that may exist in the solution.

[0024] (3) Preparation of 0.05mol / L calcium chloride solution:

[0025] Accurately weigh 5.549g of anhydrous calcium chloride solid into a 100mL glass beaker, add an appropriate amount of secondary deionized water to fully di...

Embodiment 2

[0036](1) Natural volcanic slag pretreatment process:

[0037] Weigh 0.5 kg of natural volcanic slag, place it in deionized water, shake and wash it thoroughly, drain it, and dry it in an electric drying oven at 100°C for 5 hours, then mechanically crush it, and pass it through a 200-mesh sieve for later use.

[0038] (2) Prepare 1.5% sodium alginate solution (mass percentage):

[0039] Add 500mL of deionized water into the glass beaker in advance, then place it on an electric stirrer, quickly pour 7.5g of sodium alginate solid weighed under the condition of heating at 50°C, and stir fully at a speed of 500r / min until the solution is clear Transparent, then use 100% power to sonicate for 3 minutes to remove air bubbles that may exist in the solution.

[0040] (3) Preparation of 0.2mol / L calcium chloride solution:

[0041] Accurately weigh 22.198g of anhydrous calcium chloride solid into a 500mL glass beaker, add an appropriate amount of secondary deionized water to fully dis...

Embodiment 3

[0052] (1) Natural volcanic slag pretreatment process:

[0053] Weigh 0.5 kg of natural volcanic slag, place it in deionized water, shake and wash it thoroughly, drain it, and dry it in an electric drying oven at 100°C for 5 hours, then mechanically crush it, and pass it through a 200-mesh sieve for later use.

[0054] (2) Prepare 1.5% sodium alginate solution (mass percentage):

[0055] Add 500mL of deionized water into the glass beaker in advance, then place it on an electric stirrer, quickly pour 7.5g of sodium alginate solid weighed under the condition of heating at 50°C, and stir fully at a speed of 500r / min until the solution is clear Transparent, then use 100% power to sonicate for 3 minutes to remove air bubbles that may exist in the solution.

[0056] (3) Preparation of 1.0mol / L calcium chloride solution:

[0057] Accurately weigh 110.99g of anhydrous calcium chloride solid into a 500mL glass beaker, add an appropriate amount of secondary deionized water to fully di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com