Harmless treatment process of arsenious waste dangerous chemical

A technology of harmless treatment and chemicals, applied in the direction of solid waste removal, etc., can solve problems such as hidden safety hazards, lack of harmless treatment technology for arsenic-containing hazardous chemicals, no disposal qualifications and actual disposal capacity destruction units. , to achieve the effect of strong practicability, avoiding unpredictable security risks, and eliminating hidden dangers to social security.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 pilot test process:

[0028] (1) Processing object

[0029] Suzhou Shangmei International Cosmetics Co., Ltd. contains arsenic poisonous drugs: 300g sodium arsenate, 493g diarsenic trioxide, 250g sodium arsenite, and the total arsenic in the leachate of the original mixture is higher than 50000mg / L.

[0030] (2) Treatment process

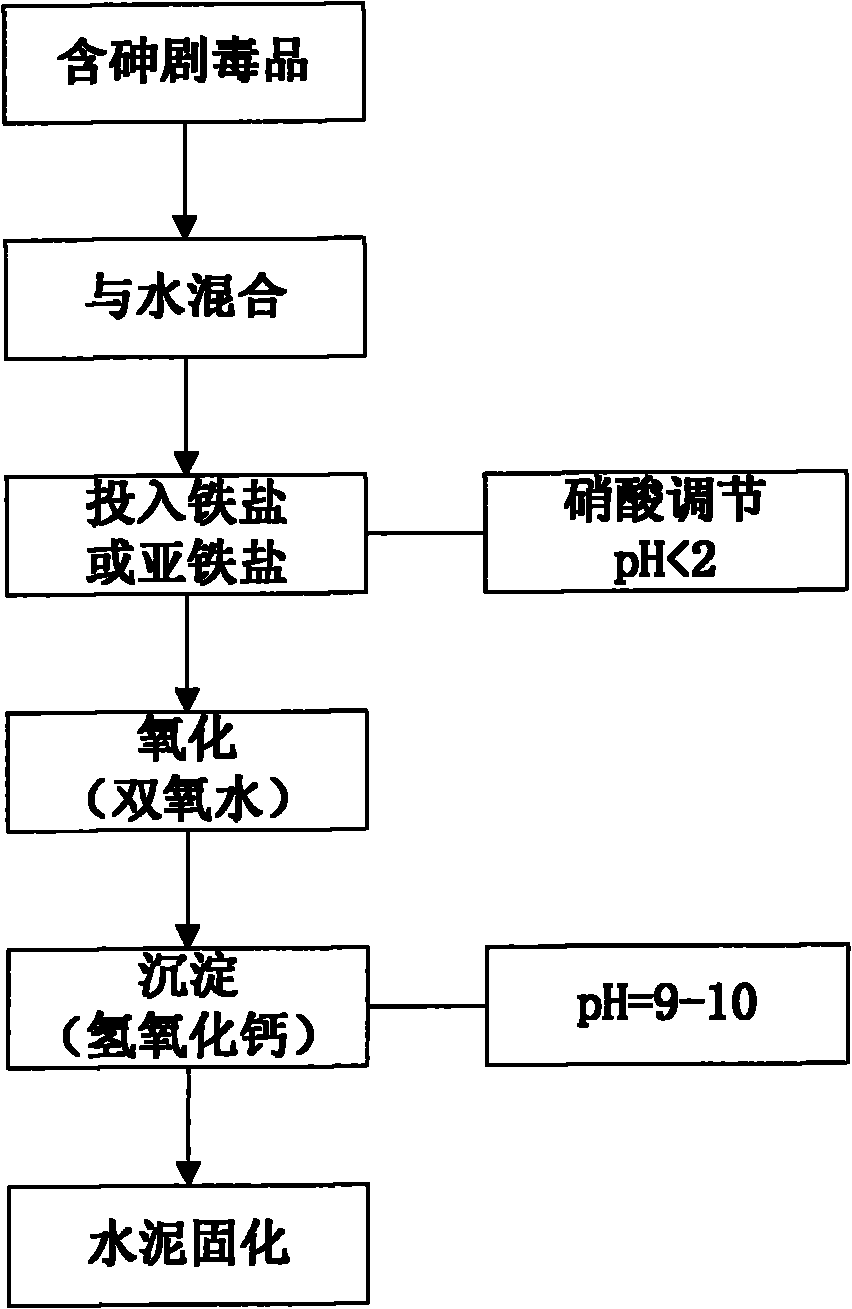

[0031] Process flow diagram as figure 1 Shown:

[0032] In a mobile reactor, add the above-mentioned arsenic-containing highly toxic mixture into water, add ferrous sulfate to form a solution, make the molar ratio of Fe and As in the solution greater than or equal to 2.5:1, and then use nitric acid to adjust the pH value of the solution to less than 2, then add hydrogen peroxide (the mass percent concentration of hydrogen peroxide is 20% to 30%) for oxidation reaction; wherein the H2O2 in the hydrogen peroxide is controlled 2 o 2 The molar ratio of arsenic to arsenic in waste containing arsenic is 3:1. After the reaction is...

Embodiment 2

[0038] Embodiment 2 engineering application:

[0039] (1) Processing object

[0040] Wujiang Lvyi Solid Waste Recycling and Disposal Co., Ltd. contains 15 tons of dangerous chemicals containing arsenic, with an arsenic content (average) of 37.18%, and leached arsenic of 29702mg / L.

[0041] (2) Process parameters of each processing unit

[0042] Reaction pool: The reaction pool is a PP structure with a size of Φ3.0m×2.2m and an effective volume of 14m 3, equipped with a stirring device with a power of 7.5kW, an exhaust system on the top (the power of the induced draft fan is 5.5kW), and a set of plate and frame filter press (80m 2 ).

[0043] Curing machine: twin-shaft forced mixer, productivity 25m 3 / h.

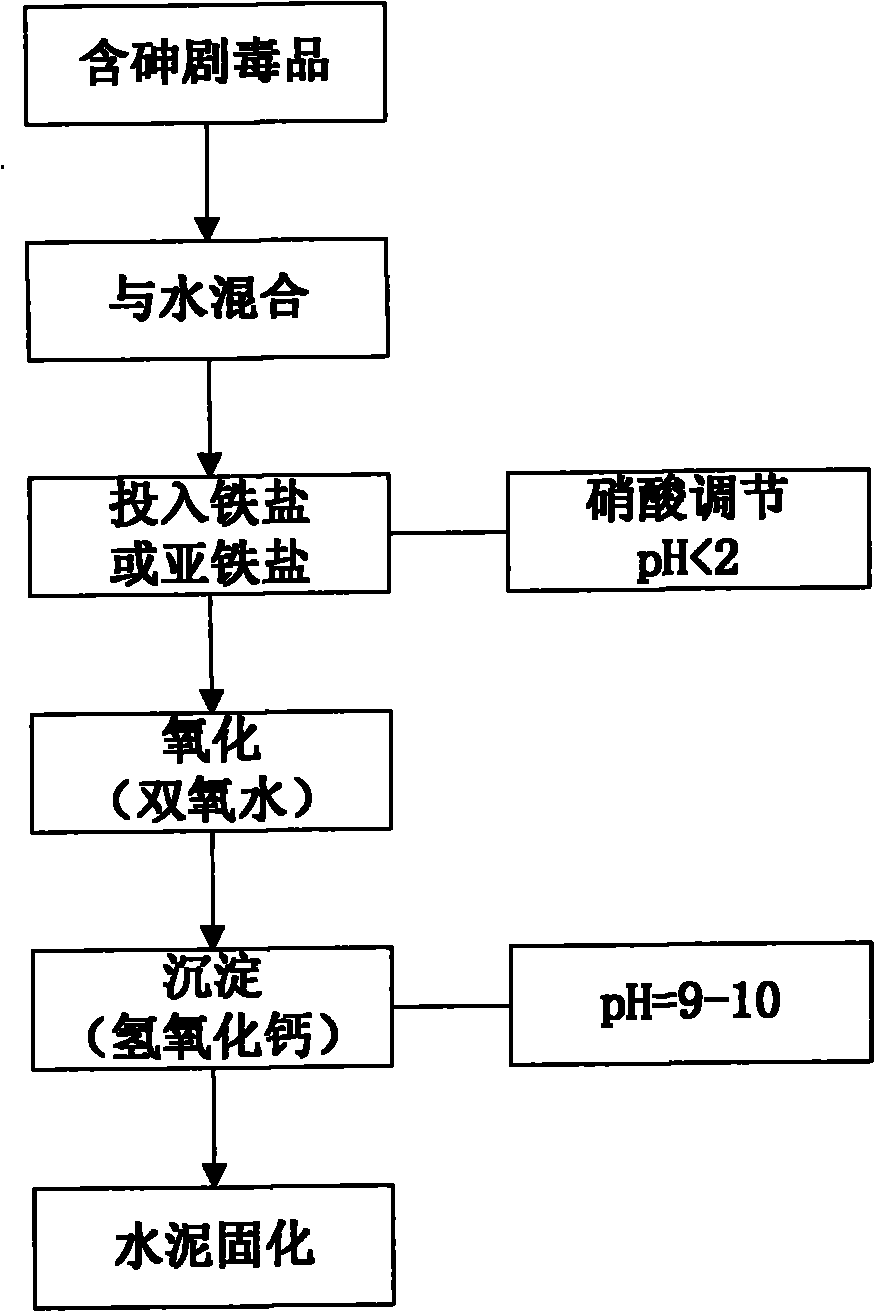

[0044] Process flow diagram as figure 1 Shown:

[0045] Put 200kg of the above-mentioned arsenic-containing dangerous chemicals into the reaction tank, add ferrous chloride aqueous solution, make the molar ratio of Fe and As in the solution be 2.5:1, then adjust the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com