High-temperature resistant Ag-Cu-O metal sealing material and use method thereof

A metal sealing, ag-cu-o technology, used in welding/cutting media/materials, metal processing equipment, welding media, etc., to ensure reliability, improve wettability, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment one: The preparation process of the high temperature resistant Ag-Cu-O metal sealing material in this embodiment is as follows:

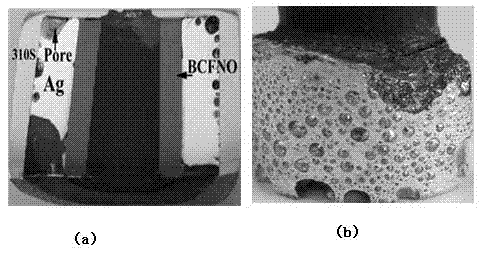

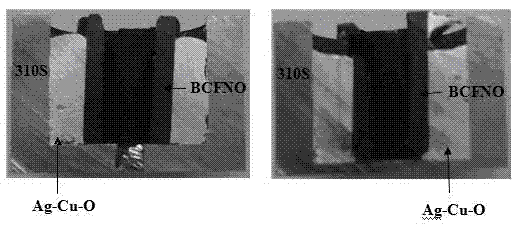

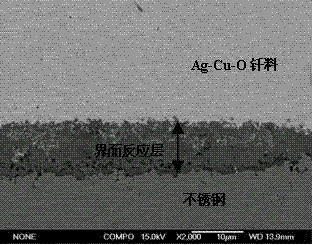

[0022] According to the mass percentages of the five components a.b.c.d.e listed in Table 1, weigh a certain amount of pure Ag and pure Cu respectively, put the mixture in a graphite crucible, and place it in a vacuum induction furnace. Melting at a temperature of 1000-1150°C for 3-5 minutes to make it melt, induction stirring evenly, and then cooling to room temperature with the furnace to obtain Ag-Cu alloy material. Place the obtained Ag-Cu alloy material in an oxygen atmosphere furnace, control the weight gain at 0.2-1.1wt%, keep it at 850°C for 30h, and then cool to room temperature with the furnace to obtain the high-temperature-resistant Ag- Cu-O metal sealing material (see Table 2). Finally, the prepared high-temperature-resistant Ag-Cu-O metal sealing material is machined or vacuum-cast into a required sealing prefa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com