Adsorption compression-multiple-effect distillation system

A technology of multi-effect distillation and adsorption bed, which is applied in water/sewage multi-stage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of fouling of heat exchange components, low operating efficiency and impossibility Achieve the effects of improving water production ratio and thermal efficiency, strong heat source adaptability, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

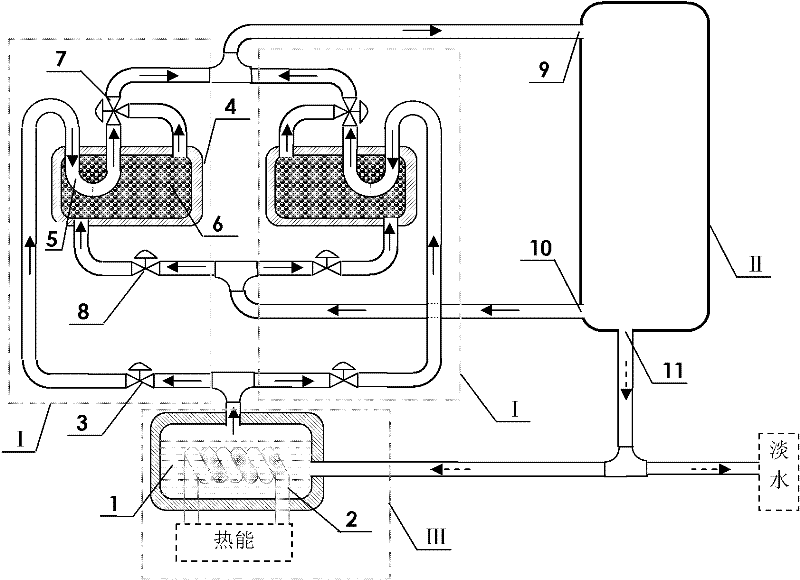

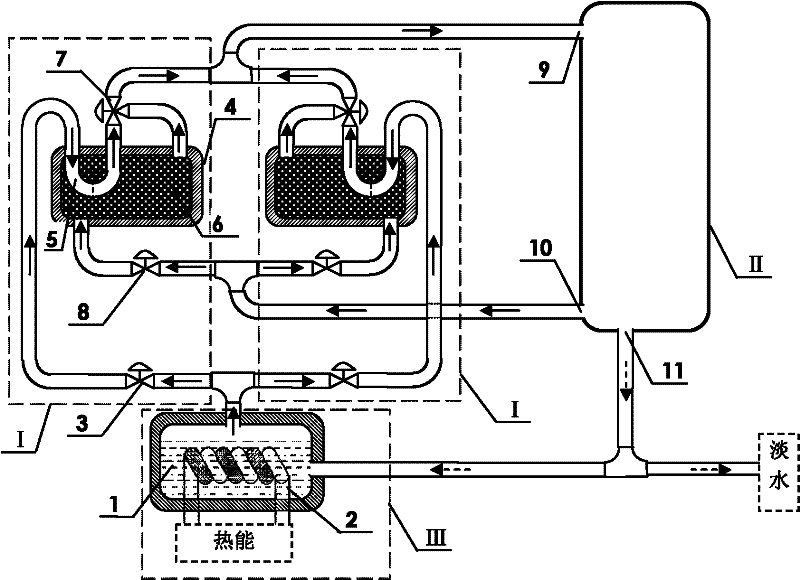

[0019] Such as figure 1 As shown, this embodiment includes: an adsorption module I, a multi-effect distillation module II, and a steam generation module III. The adsorption module I is provided with a heating valve 3, an adsorption bed 4, a heating valve 7 and an air supplement valve 8. In the effective distillation module II, there are the first-stage distillation device spray falling film evaporator steam inlet 9, the last-stage distillation device steam outlet 10 and fresh water outlet 11, and the steam generation module III has fresh water 1 and heat exchanger 2, and adsorption bed There are condenser 5 and adsorbent 6 in 4.

[0020] In this embodiment, the left port of the heating valve 3 is connected to the inlet of the condenser 5, the outlet of the condenser 5 is connected to the lower port of the heating valve 7, the upper port of the adsorption bed 4 is connected to the right port of the heating valve 7, and the upper port of the heating valve 7 Connected to the first-...

Embodiment 2

[0025] In this embodiment, the number of adsorption modules I is three, and each adsorption module I alternately operates in an adsorption heating state and a desorption heating state.

[0026] In this embodiment, the heat source of the heating module is high-pressure water vapor generated by the solar energy medium and high temperature system. The heating module is removed, and the hot water vapor directly enters the heating valve as a heat source for heating the adsorbent. The greater the heat supply, the more the number of adsorption modules I work to maintain the adaptability of the system to the fluctuation of the heat source. At the same time, one adsorption module I always keeps one in the adsorption heating state, and the remaining two are in the desorption heating state.

[0027] In this embodiment, the heating temperature of the external heat source fluid is 220°C, which is converted into 70°C medium-pressure steam by the adsorption module, which is used as the driving he...

Embodiment 3

[0029] In this embodiment, the number of adsorption modules I is 8, and each adsorption module I alternately operates in an adsorption heating state and a desorption heating state.

[0030] In this embodiment, the heat source of the heating module is high-pressure water vapor generated by the solar energy medium and high temperature system. The heating module is removed, and the hot water vapor directly enters the heating valve as a heat source for heating the adsorbent. The greater the heat supply, the more the number of adsorption modules I work to maintain the adaptability of the system to the fluctuation of the heat source. At the same time, the adsorption module I always keeps half of it in the adsorption heating state, and the other half in the desorption heating state.

[0031] In this embodiment, the temperature of the external heat source fluid is 150°C, which is converted into 65°C medium-pressure steam by the adsorption module, which is used as the driving heat source of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com