Method for preparing vinyl chloride from 1,2-dichloroethane

A dichloroethane production, dichloroethane technology, applied in the direction of dehydrohalogenation preparation, chemical recovery, etc., can solve problems that have not been seen yet, achieve good industrialization prospects, reduce energy consumption, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

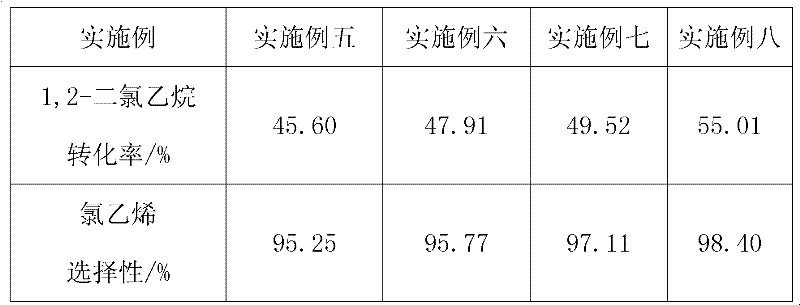

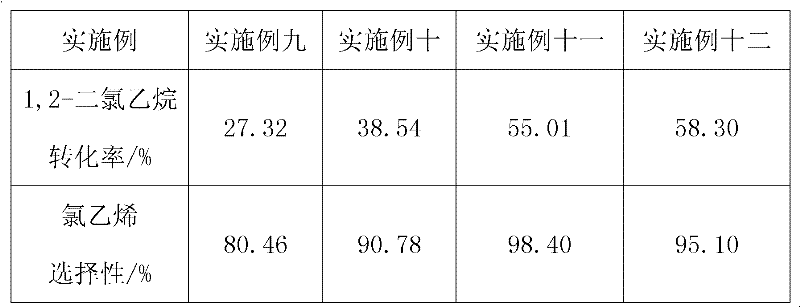

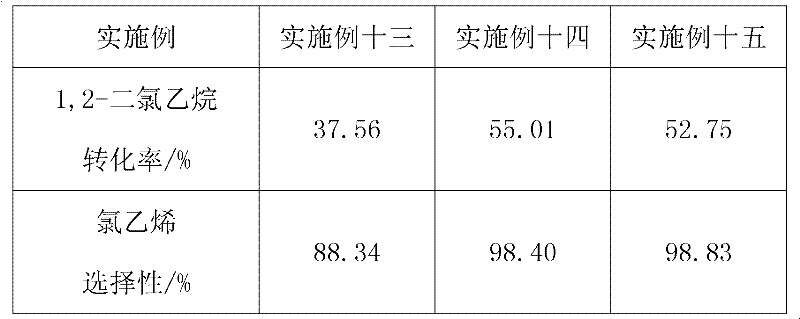

Examples

Embodiment 1

[0015] 25.7g pseudoboehmite (Al 2 o 3 Content 64.59wt%) is dissolved in 89.2ml deionized water, then adds 2.0g ferric nitrate [Fe(NO 3 ) 3 9H 2 O], add 76.1g phosphoric acid (85wt%) under stirring, then add 18.5g silica sol (SiO 2 Content 30wt%), finally add 49.5g triethylamine, continue to stir until uniform, move the above mixture into the reaction kettle, crystallize in an oven at 190°C for 72 hours, take out the reaction kettle and put it in cold water to cool to room temperature, filter and dry Then calcined at 550° C. for 8 hours to obtain Fe-modified SAPO-34 molecular sieve catalyst. The Fe content is 0.5 wt%.

Embodiment 2

[0017] According to the synthesis steps in Example 1, with 1.3g magnesium nitrate [Mg(NO 3 ) 2 ·6H 2 O] instead of iron nitrate [Fe(NO 3 ) 3 9H 2 O], obtain the SAPO-34 molecular sieve catalyst of Mg modification. The Mg content is 0.8 wt%.

Embodiment 3

[0019] According to the synthesis steps in Example 1, with 1.2g manganese acetate [Mn(CH 3 COO) 2 4H 2 O] instead of iron nitrate [Fe(NO 3 ) 3 9H 2 O] to obtain a Mn-modified SAPO-34 molecular sieve catalyst. The Mn content is 0.9 wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com