D-sorbitol crystalline solid and preparation method thereof

A technology of crystalline solid and sorbitol, applied in the field of D-sorbitol crystalline solid and preparation thereof, can solve the problems of difficult filtration, viscous crystal slurry, low crystallinity, etc., and achieves simple and easy-to-control operating conditions and good crystal habit. , the effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Add 20g of Gamma-type D-sorbitol solid into 100g of N,N-dimethylformamide, heat up to 30°C to dissolve completely, then cool the solution down to 5°C, and separate the resulting solid-liquid suspension by suction filtration , and the resulting solid was dried. The micrograph of the sorbitol product after drying is as Figure 5 As shown, the product is a rod-shaped crystal, and the crystal habit is better than that of Gamma-type granular aggregates.

[0031] The dried product was analyzed and determined, and the PXRD pattern had characteristic peaks at diffraction angles 2θ=7.4, 12.8, 14.8, 19.8, 22.6, 24.0, 26.0, 27.1, 32.7, 38.2 and 39.6 degrees, and DSC had a peak at 75.0°C Melting endothermic peaks, FTIR spectrum at 3376, 2931, 1635, 1418, 1316, 1258, 1196, 1105, 1092, 1050, 1017, 938, 894, 874, 644, 588, 506 and 480cm -1 There are characteristic peaks at 1248, 1132, 1096, 1060, 1020, 962, 941, 876, 775, 742, 645, 595, 505, 478, 412, 354 and 250cm -1 There are cha...

Embodiment 2

[0033] Add 50g of F-type D-sorbitol solid mixture into 100g of N,N-dimethylacetamide, heat up to 70°C to dissolve completely, cool down to 30°C at a cooling rate of 5°C / h, and filter the solid Liquid suspension, the suction filtration time is 6min, which saves more than half than the suction filtration time (greater than 30min) of other methods for D-sorbitol crystal preparation. The obtained solid was dried at 30° C. and a vacuum of 0.1 MPa. After drying, the sorbitol product is a rod-shaped crystal.

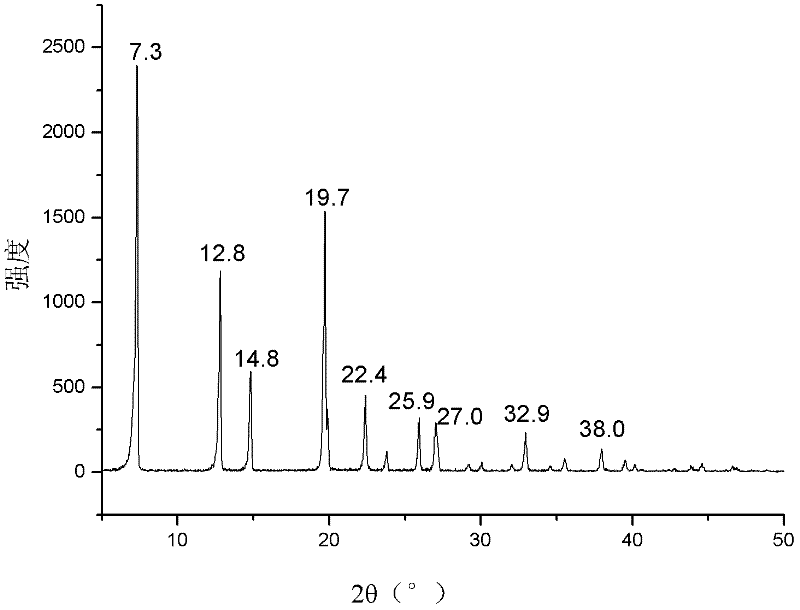

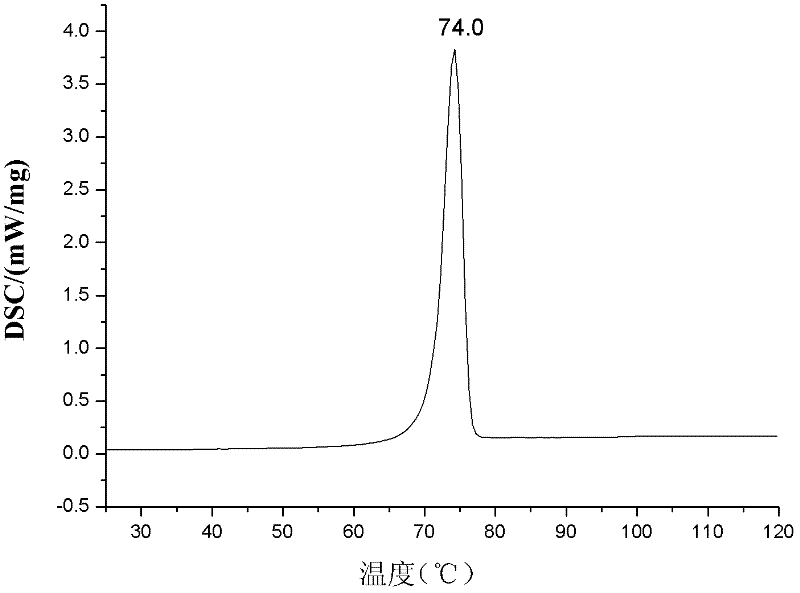

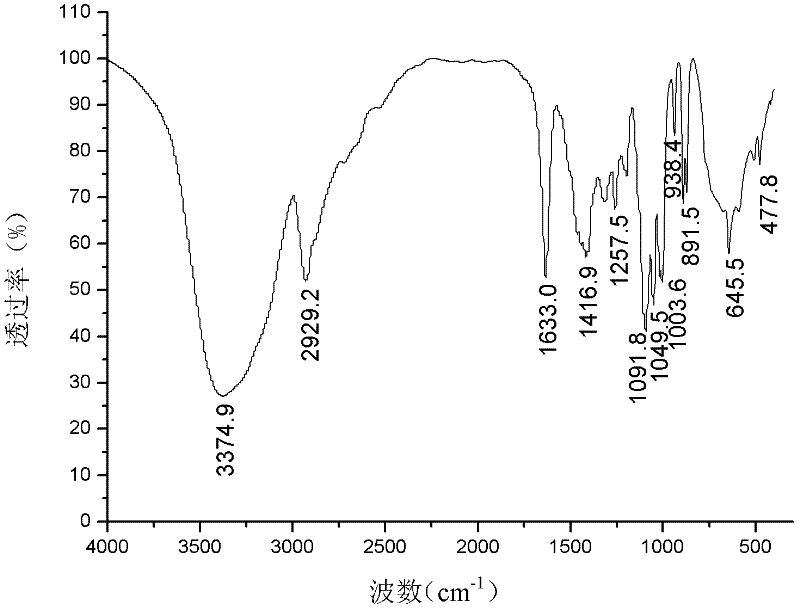

[0034] The dried product was analyzed and determined, and the PXRD pattern had characteristic peaks at diffraction angles 2θ=7.3, 12.8, 14.8, 19.7, 22.4, 23.8, 25.9, 27.0, 32.9, 38.0 and 39.5 degrees, and DSC had a peak at 74.0°C Melting endothermic peaks, FTIR spectrum at 3374, 2928, 1631, 1415, 1315, 1260, 1195, 1105, 1094, 1049, 1016, 940, 893, 873, 643, 589, 507 and 478cm -1 There are characteristic peaks at 1249, 1131, 1094, 1059, 1018, 961, 942, 878, 774, 741, 647, 597,...

Embodiment 3

[0036] Add 30g of Gamma-type D-sorbitol solid into 100g of formamide, heat up to 70°C, stir to dissolve completely, cool down to 20°C at a cooling rate of 8°C / h, and filter the solid-liquid suspension with suction. 10min. The obtained solid was dried at 40° C. and a vacuum of 0.09 MPa. After drying, the sorbitol product is a rod-shaped crystal.

[0037] The dried product was analyzed and determined, and the PXRD pattern had characteristic peaks at diffraction angles 2θ=7.1, 12.6, 14.6, 19.8, 22.4, 23.8, 25.8, 26.9, 32.8, 38.0 and 39.3 degrees, and DSC had a peak at 73.4°C. Melting endothermic peaks, FTIR spectrum at 3375, 2930, 1635, 1416, 1317, 1257, 1197, 1106, 1091, 1050, 1015, 937, 892, 871, 645, 589, 508 and 479cm -1 There are characteristic peaks at 1247, 1131, 1094, 1059, 1019, 961, 941, 878, 774, 740, 645, 595, 504, 477, 411, 354 and 249cm in the Raman spectrum -1 There are characteristic peaks, and the product is F-type D-sorbitol. The characteristic peaks of its ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com