Method for purifying high-purity transacomhole

A technology of trans-anethole and purification method, which is applied in the field of purification of high-purity trans-anethole, can solve the problems of long process cycle and heavy workload, and achieve the effects of high product purity, low environmental pollution and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

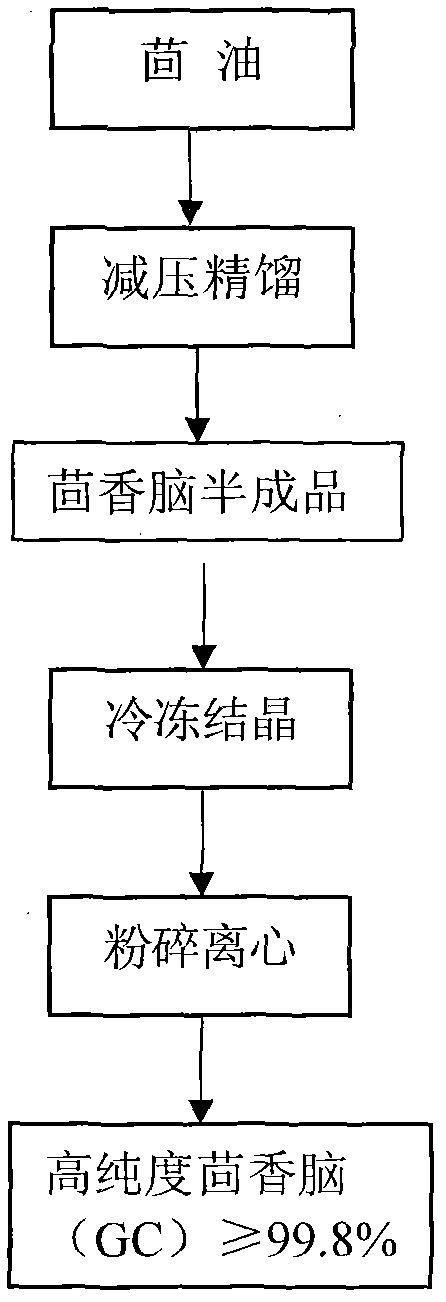

Method used

Image

Examples

example 1

[0021] 3536.2 kilograms of fennel oil, with a trans-anethole content (GC) of 87.811%, are put into a rectification tower for rectification. The pressure in the tower is constant at 100 Pa, and the kettle temperature is at 100° C. to obtain 2599.7 kilograms of anethole semi-finished products. The trans-anethole content ( GC) 97.673%. Put the semi-finished product of anethole into the freezer for freezing, the freezing time is 12 hours, and the freezing temperature is -3°C. Crush the frozen crystals to a size of about 15 mesh sieves, centrifuge the crushed body with a centrifuge at a speed of 1500r / min, and centrifuge for 30 minutes. The centrifuged liquid is subjected to secondary freezing, crushing, and centrifugation in the above-mentioned manner to obtain anethole The product finally obtained 2535.5 kg of anethole product, the content of trans-anethole (GC) was 99.737%, and the total yield was 71.7%.

example 2

[0023] With 3178.6 kilograms of fennel oil, trans-anethole content (GC) 87.829%, put into rectifying column rectification, the pressure in the tower is constant 105Pa, and kettle temperature is at 105 ℃, obtains 2256.5 kilograms of anethole semi-finished products, trans-anethole content ( GC) 98.192%, put the semi-finished product of anethole into the freezer for freezing, the freezing time is 16 hours, the freezing temperature is 5°C, the frozen crystals are crushed to the size of about 15 mesh sieves, and the crushed body is centrifuged with a centrifuge at a speed of 1500r / min , centrifuged for 30 minutes, and the centrifuged liquid was subjected to secondary freezing, pulverization, and centrifugation to obtain the anethole product in the above-mentioned manner, finally obtaining 2298.1 kilograms of anethole product, trans-anethole content (GC) 99.704%, and a total yield of 72.3% .

example 3

[0025] Put 2568.7 kilograms of fennel oil with trans-anethole content (GC) of 87.947% into a rectification tower for rectification. The pressure in the tower is constant at 110 Pa, and the kettle temperature is at 105° C. to obtain 1756.3 kilograms of anethole semi-finished products. The trans-anethole content ( GC) 97.216%, put the semi-finished product of anethole into the cold storage for freezing, the freezing time is 15 hours, the freezing temperature is -1°C, the frozen crystals are crushed to the size of about 20 mesh sieves, and the pulverized body is centrifuged with a centrifuge at a speed of 1600r / min, centrifuged for 30 minutes, and the centrifuged liquid was subjected to secondary freezing, crushing, and centrifugation to obtain anethole products in the above-mentioned manner, and finally obtained 1872.6 kg of anethole products, with a trans-anethole content (GC) of 99.823%, and a total yield of 72.9 %.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com