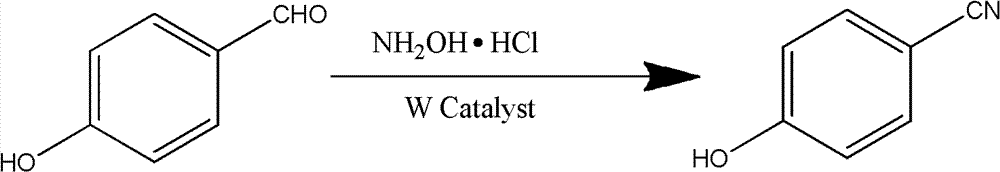

Synthetic method of p-hydroxybenzonitrile

A technology for p-hydroxybenzonitrile and p-hydroxybenzaldehyde is applied in the field of p-hydroxybenzonitrile synthesis, can solve problems such as three wastes and the like, and achieve the effects of simple steps and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

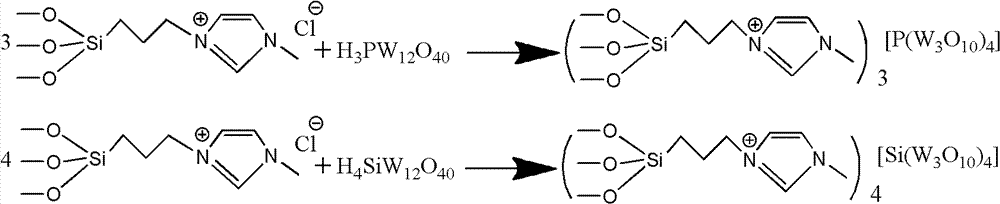

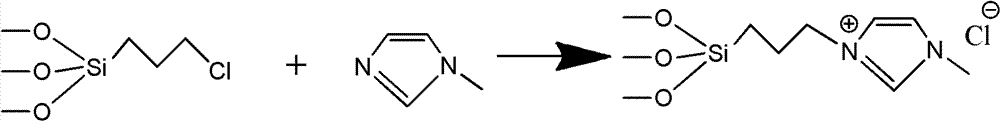

[0025] Embodiment 1: the preparation of catalyst 1

[0026] h 3 PW 12 o 40 +3(n-C 4 h 9 ) 4 NOH→[(n-C 4 h 9 ) 4 N] 3 [P(W 3 o 10 ) 4 ]

[0027] Tetrabutylammonium hydroxide (25% methanol solution) 6.2g, phosphotungstic acid 5.8g, add 20ml water and stir for 3h, then add 14.6g silicon oxide and stir for 24h, evaporate the solvent to obtain the required catalyst; The mass ratio of silicon is 1:2.

Embodiment 2

[0028] Embodiment 2: the preparation of catalyst 2

[0029] h 4 SiW 12 o 40 +4(n-C 4 h 9 ) 4 NOH→[(n-C 4 h 9 ) 4 N] 4 [Si(W 3 o 10 ) 4 ]

[0030]Tetrabutylammonium hydroxide (25% methanol solution) 8.3g, silicotungstic acid 5.8g, add 20ml of water and stir for 3h, then add 15.6g of silicon oxide and stir for 24h, evaporate the solvent to get the required catalyst; The mass ratio of silicon is 1:2.

Embodiment 3

[0031] Embodiment 3: the preparation of catalyst 3

[0032] h 3 PW 12 o 40 +3(n-C 4 h 9 ) 4 POH→[(n-C 4 h 9 ) 4 P] 3 [P(W 3 o 10 ) 4 ]

[0033] Tetrabutyl phosphorus hydroxide (40% solution) 4.1g, phosphotungstic acid 5.8g, add 20ml water and stir for 3h, then add 29.2g silicon oxide and stir for 24h, evaporate the solvent to get the required catalyst; wherein phosphotungstate and silicon oxide The mass ratio is 1:4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com