Method for extracting camellia oil by using microwave assisted aqueous extraction method

A microwave-assisted, camellia oil technology, which is applied in the direction of fat oil/fat production, fat production, animal feed, etc., can solve the problems of easy residual solvent, high cost, and low price, and achieve simple process operation, fast extraction speed, and low solvent consumption. The effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

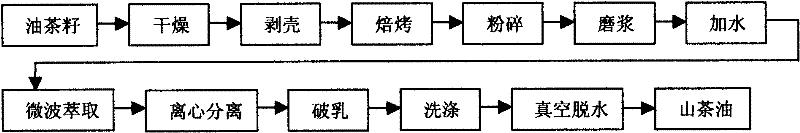

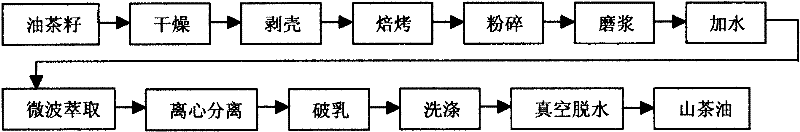

[0014] It can be seen from the accompanying drawings that the dried camellia seed shells are crushed with a disc sheller to separate the kernels and shells, and the peeled camellia seed kernels are baked at 180°C for 30 minutes, then crushed and ground to a particle size of <10 μm. The pulverized and ground camellia seed slurry was uniformly mixed with water at a mass ratio of 1:4, heated and stirred at a temperature of 70°C for extraction, and the extraction reaction was carried out for 30 minutes under microwave radiation with a power of 800W. The extract liquid obtained by the reaction is separated by a decanter decanter centrifuge to separate emulsified oil and protein slurry. After adding a demulsifier to the emulsified oil and stirring to break the emulsified oil, add 10% hot water to wash, centrifuge to remove water residues, and vacuum dehydrate to obtain camellia oil. The method of extracting camellia oil by using microwave-assisted water substitution method has the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com