Method for preparing rubusoside by catalytically hydrolyzing stevioside with beta-galactosidase

A technology of galactosidase and steviol glycosides, which is applied in the field of biosynthesis of organic compounds, can solve problems such as inability to prove steviolbiosides, lack of structural characterization, and difficulty in product separation, and achieve expanded applications, high selectivity, and product separation and purification simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

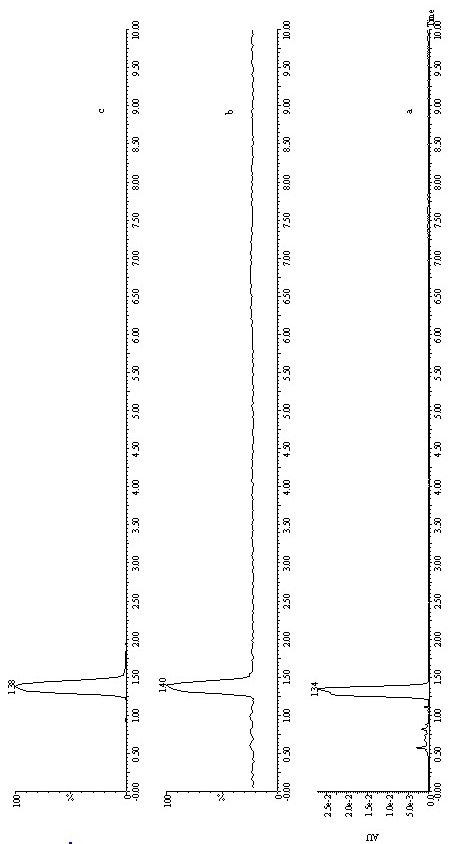

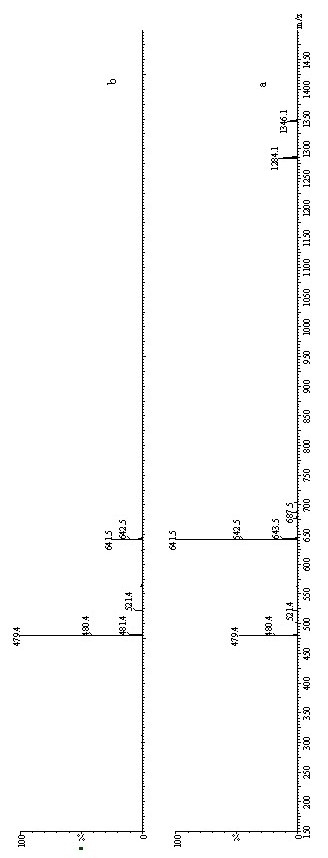

[0025] Dissolve 20g St in 100mL deionized water, shake in a water bath shaker and shake at 50 o C under constant temperature for 0.5h, the shaker speed is 150rpm; add β -Galactosidase enzyme solution 14000U / g St; after 4 hours of reaction, the conversion rate of St does not increase. St conversion was 99%. The reaction solution was boiled for 10 minutes to inactivate the enzyme, and after centrifugation, the supernatant was concentrated and dried. Add 2g of crude product to 20mL of methanol; continue to stir and heat to reflux; gradually add methanol dropwise until the solution is clear, the total amount of methanol added is about 160mL; leave to cool naturally to precipitate crystals, filter and dry the crystals; repeat the above steps for two times After recrystallization, 1.2 g of a product with a content greater than 97% can be obtained at last. Select column chromatography silica gel (200-300 mesh), with chloroform, methanol and water as eluent 5:5:1 ( v / v / v ), accor...

Embodiment 2

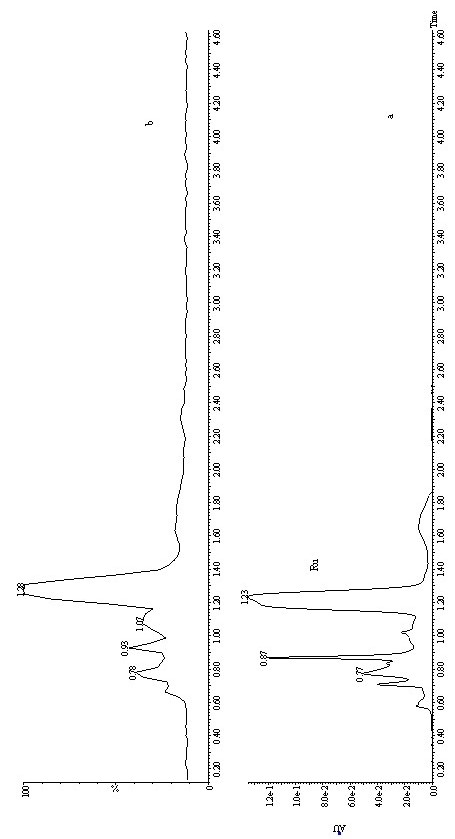

[0027] First, the enzyme was immobilized, AB-8 resin 0.1g, 0.5mL enzyme solution was dissolved in phosphate buffer solution of pH 6 to prepare a 20mL system, and the temperature was 4 o C fixed for 5h, after immobilization β - Galactosidase in 5% CaCl 2 The solution was preserved, and the enzyme activity was determined to be 20000U / g by FCCIV method. Dissolve 1g St in 100mL deionized water, put it in a water bath shaker and shake it at 50 o C for 0.5h at constant temperature, the shaker speed is 150rpm; add immobilized β -Galactosidase reaction 10000U / g St; regular sampling for HPLC analysis, until the St conversion rate no longer changes ( Figure 5 ). The reaction solution mainly contains rubusoside and glucose hydrolyzed. Reclaim the immobilized enzyme, concentrate and dry the gained rubusoside crude product (80% rubusoside, 20% glucose, w / w ) can be used in food and other fields. The specific characterization of the product is described in the technical scheme part...

Embodiment 3

[0029] Dissolve 1g St in 100mL deionized water, put it in a water bath shaker and shake it at 50 o C for 0.5h at constant temperature, the shaker speed is 150rpm; add immobilized β - Galactosidase 10000U / g St; react for 5 hours until the St conversion rate no longer increases. The immobilized enzyme is recovered and purified by recrystallization to obtain rubusoside with a content greater than 97%. The specific characterization of the product is described in the technical scheme part.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com