Cyclic regeneration and copper extraction process for printed circuit board etching waste solution

A printed circuit board, copper extraction process technology, applied in the direction of process efficiency improvement, etc., can solve the problem of increasing device operating costs and maintenance costs, high requirements for extraction agent phase separation time, low operating reliability and stability, etc. problems, to achieve good economic and social benefits, low maintenance costs, and low investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

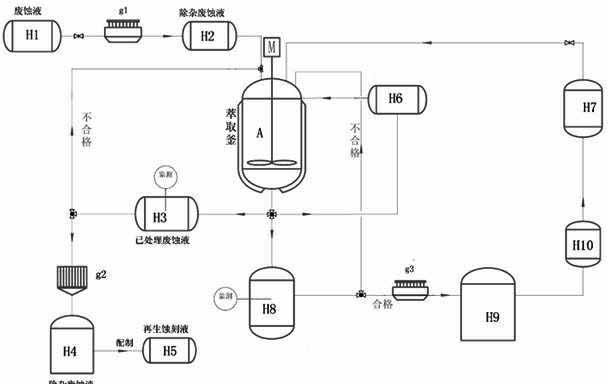

[0034] Such as figure 1 As shown, 100L of the alkaline waste etching solution in the first storage tank H1 is filtered through the first filter g1 to remove impurities, and the obtained waste etching solution is stored in the second storage tank H2. Put the impurity-removing waste etching solution in the second storage tank H2 and 100L of Mextral PCB-2011b extractant into the extraction kettle A and stir for 0.5 hours for extraction. Stop stirring and let the layers stand for 20 minutes. Liquid separation, the upper copper-containing organic phase in the extraction kettle A is left in the extraction kettle, and the extracted waste etching solution of the lower layer is put into the third storage tank H3. After the sampling analysis is qualified, the second filter g2 is filtered, and the filtrate is stored in the fourth storage tank H4, and the formula components of the etching solution are added for preparation to obtain a regenerated etching solution, which is stored in the ...

Embodiment 2

[0038] Such as figure 1 As shown, 5000L alkaline waste etching solution in the first storage tank H1 is filtered through the first filter g1 to remove impurities, and the obtained waste etching solution is stored in the second storage tank H2. Put the impurity-removing waste etching solution in the second storage tank H2 and 6000L of Mextral PCB-2011b extractant into the extraction kettle A and stir for 0.5 hours for extraction. Stop stirring and let the layers stand for 20 minutes. Liquid separation, the upper copper-containing organic phase in the extraction kettle A is left in the extraction kettle, and the extracted waste etching solution of the lower layer is put into the third storage tank H3. After the sampling analysis is qualified, the second filter g2 is filtered, and the filtrate is stored in the fourth storage tank H4, and the formula components of the etching solution are added for preparation to obtain a regenerated etching solution, which is stored in the fifth...

Embodiment 3

[0042] Filter 200L of the acid waste etching solution through a filter to obtain the waste etching solution for removal of impurities. Put the waste etching solution and 400L of Mextral PCB-2011a extractant into the extraction kettle A and stir for 0.5 hours for extraction. Stop stirring and let the layers stand for 20 minutes. Liquid separation, the upper copper-loaded organic phase is kept in the extraction kettle A, and the extracted waste etching solution of the lower layer is put into the third storage tank H3. After the sampling analysis is qualified, it is filtered, and the filtrate is stored in the fourth storage tank H4, and the ingredients of the etching solution formula are added to prepare the regenerated etching solution.

[0043] Add 200 L of 0.1% sodium bicarbonate solution to the copper-loaded organic phase left in extraction kettle A, stir and wash for 40 minutes. Stop stirring and let the layers stand for 20 minutes. The lower layer of sodium bicarbonate w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com