Method for manufacturing micro lens array based on digital mask lithography technology

A microlens array and lithography technology, applied in the field of microlens array fabrication based on digital mask lithography technology, can solve problems such as pattern distortion, reduce data volume, improve optical performance, and reduce errors. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

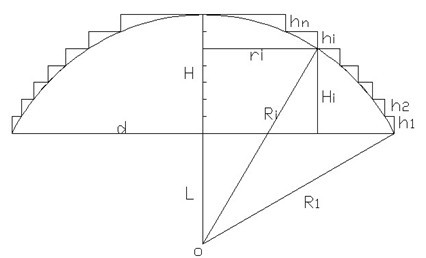

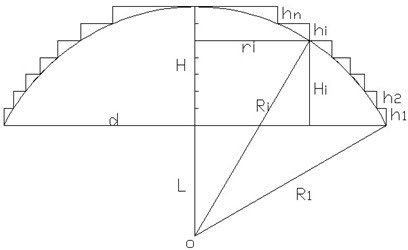

[0011] exist figure 1 In the n-order equal-height quantization of the microlens, there are:

[0012]

[0013] in Quantize the height in units;

[0014] according to figure 1 It can be seen that:

[0015]

[0016] That is, the height of the step after the actual exposure and etching, which determines the exposure amount correspondingly during the exposure process. In the present invention, equal-height quantization is adopted, so there is a multiple relationship between each exposure height, which can help us set the time interval of exposure of each mask pattern.

[0017] exist figure 1 , according to the Pythagorean theorem, we can know the relationship between the lengths of each side:

[0018]

[0019] then there is the first The radius of the plane circle corresponding to the steps:

[0020]

[0021] then there is the first The diameter of the plane circle corresponding to the steps:

[0022]

[0023] Then for the resulting diameter Carry ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com