Method for manufacturing resistive type memory

A resistive and memory technology, applied in the manufacture of semiconductor/solid-state devices, circuits, electrical components, etc., can solve the problems of voids, difficult to effectively control the distribution of O elements, and poor uniformity of the film, so as to eliminate the activation voltage and reduce the production cost. Low, the effect of improving the device yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Hereinafter, the method for preparing the resistance type memory according to the present invention will be described with reference to the accompanying drawings.

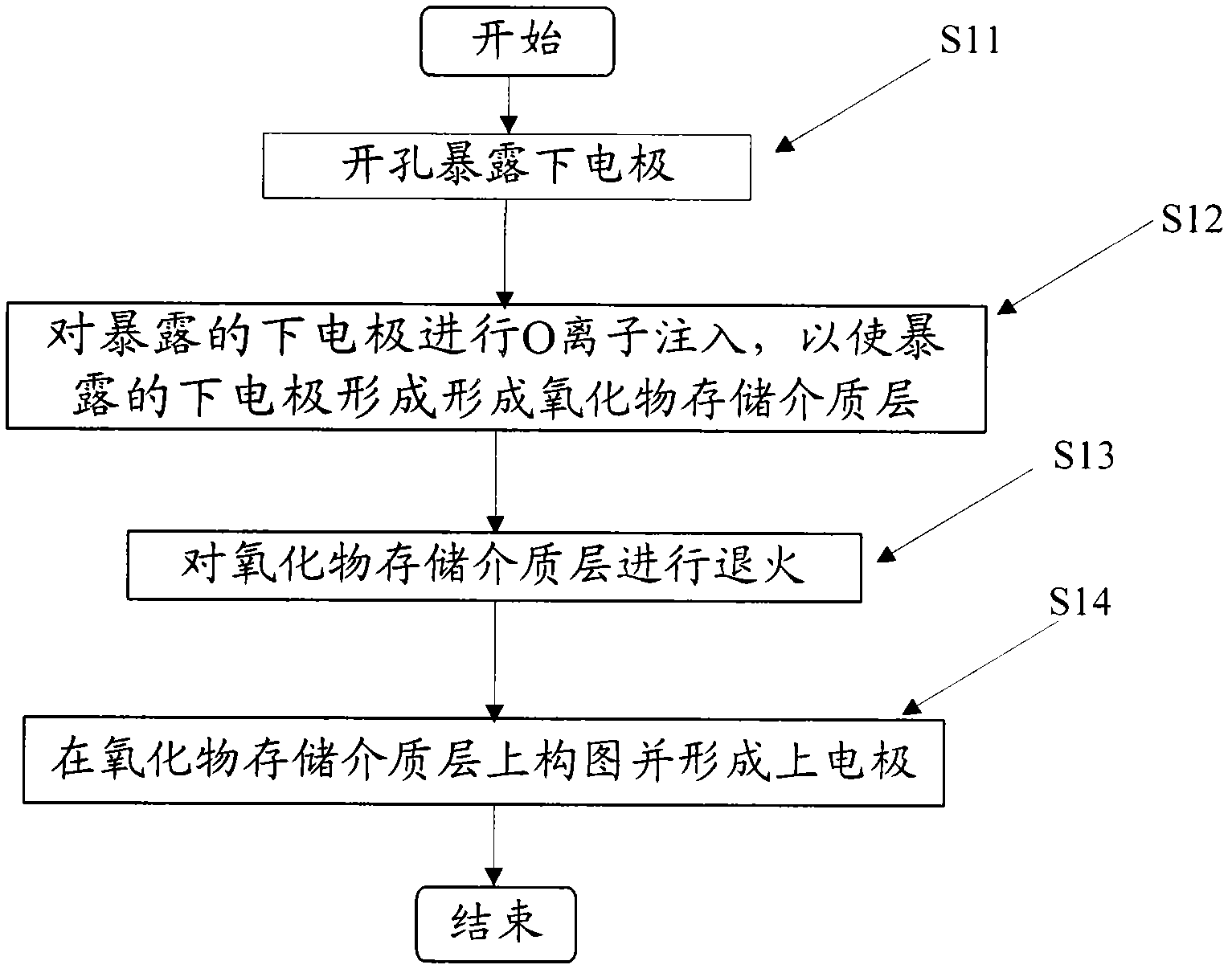

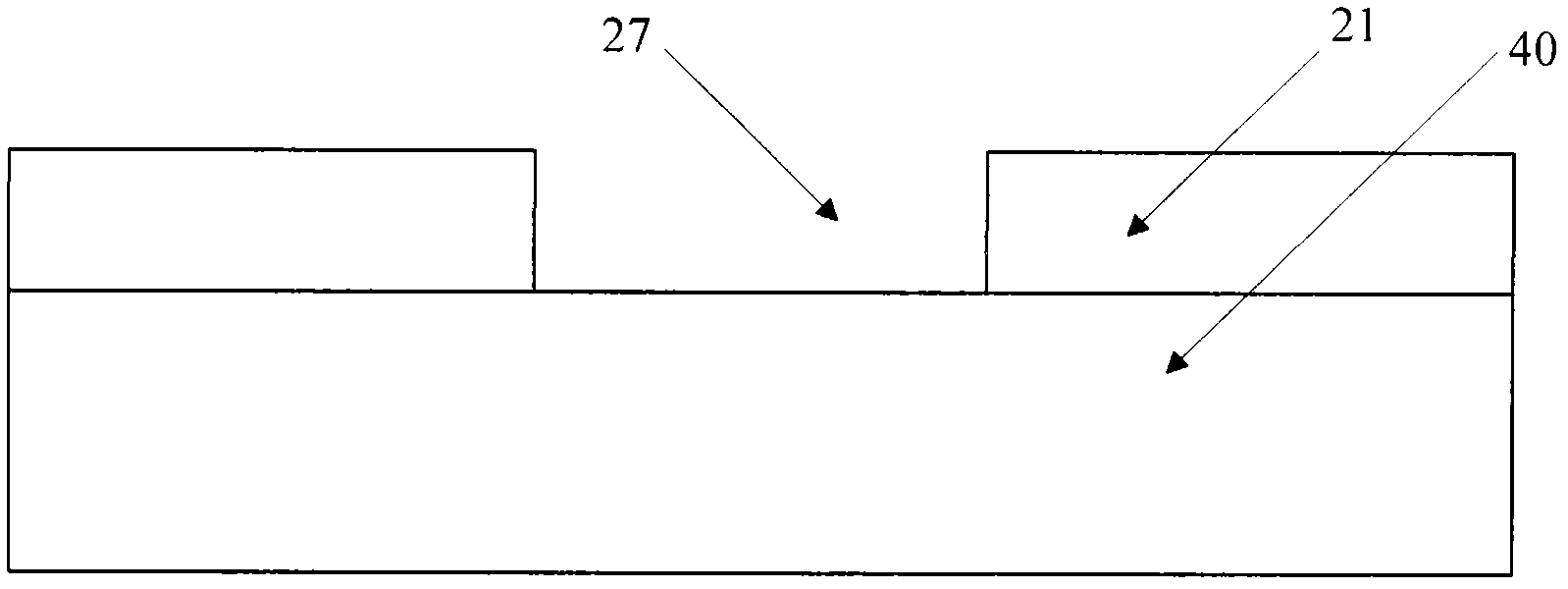

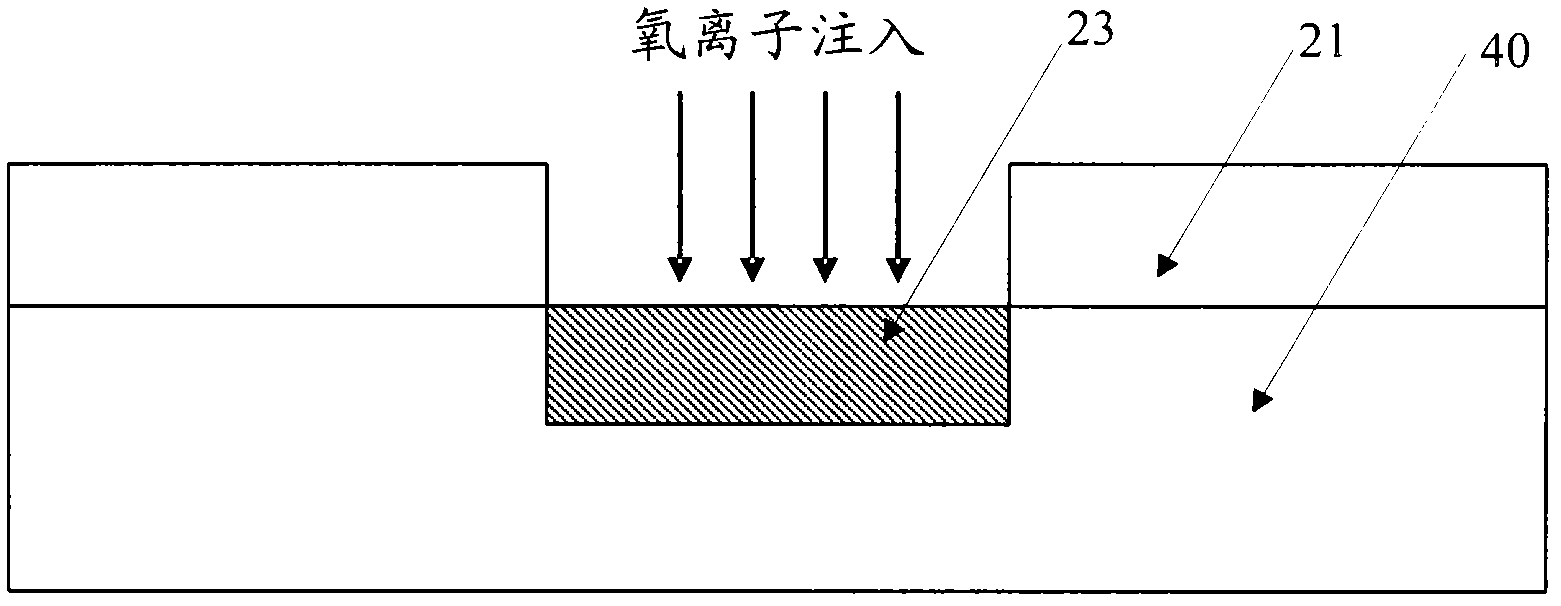

[0043] figure 1 Is a flow chart of the method for manufacturing a resistive memory according to the present invention, Figure 2 to Figure 4 It is a schematic structural decomposition diagram of the manufacturing method of the resistive memory according to the present invention. The following combination Figure 1 to Figure 4 The manufacturing method of the resistive memory is described in detail.

[0044] Reference figure 1 And combine Figure 2 to Figure 4 , The manufacturing method of the resistive memory according to the present invention includes: step S11, opening a hole to expose the bottom electrode, figure 1 with figure 2 As shown; Step S12, O ion implantation is performed on the exposed bottom electrode, so that the exposed bottom electrode forms an oxide storage medium layer, such as figure 1 with ima...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com