Nanopillar array-based photoelectric device and manufacturing method thereof

A nano-pillar array, optoelectronic device technology, applied in photovoltaic power generation, electrical components, semiconductor devices, etc., can solve the problems of low yield, inability to accurately control the thickness and flatness of fillers, etc., to increase yield and improve stability and device reliability, damage prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and a preferred embodiment.

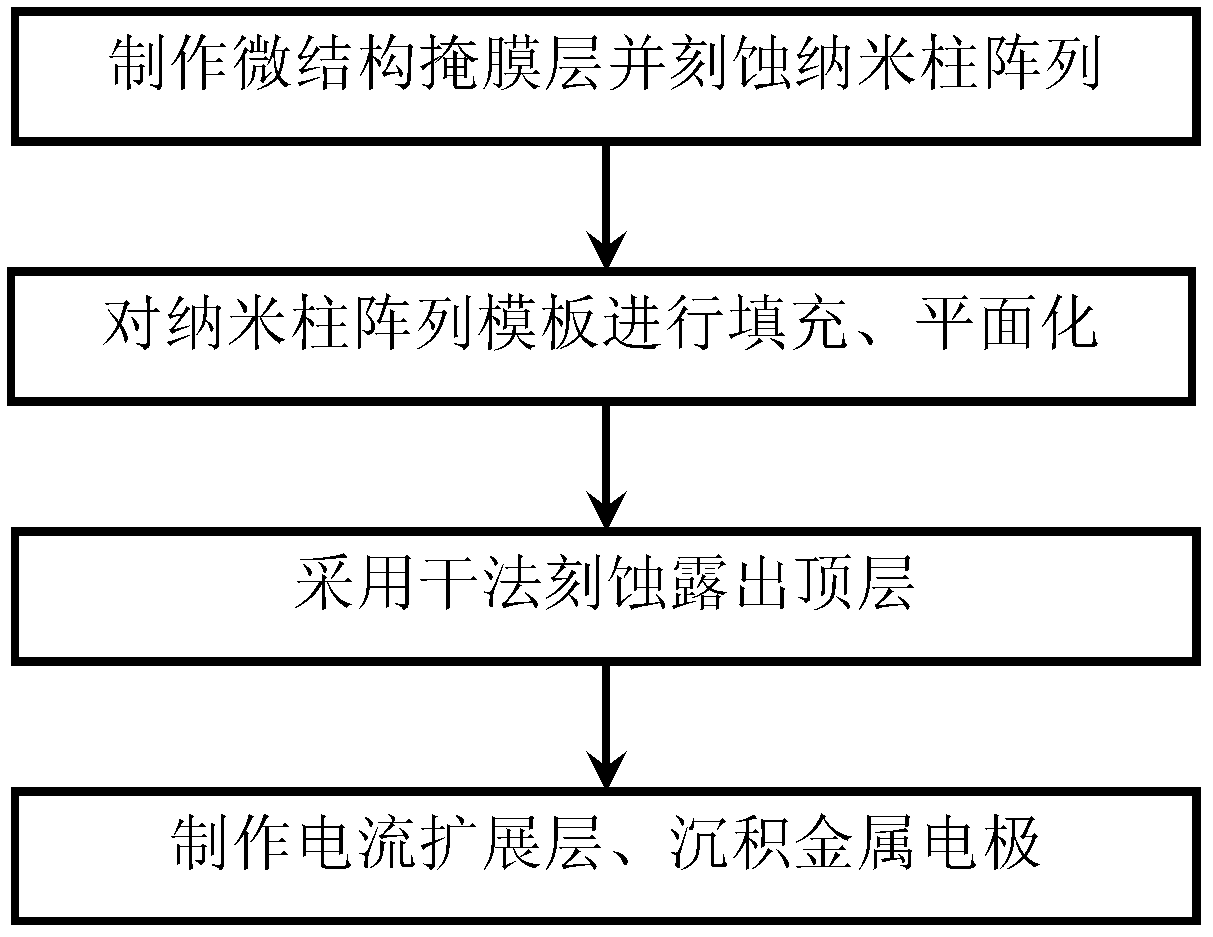

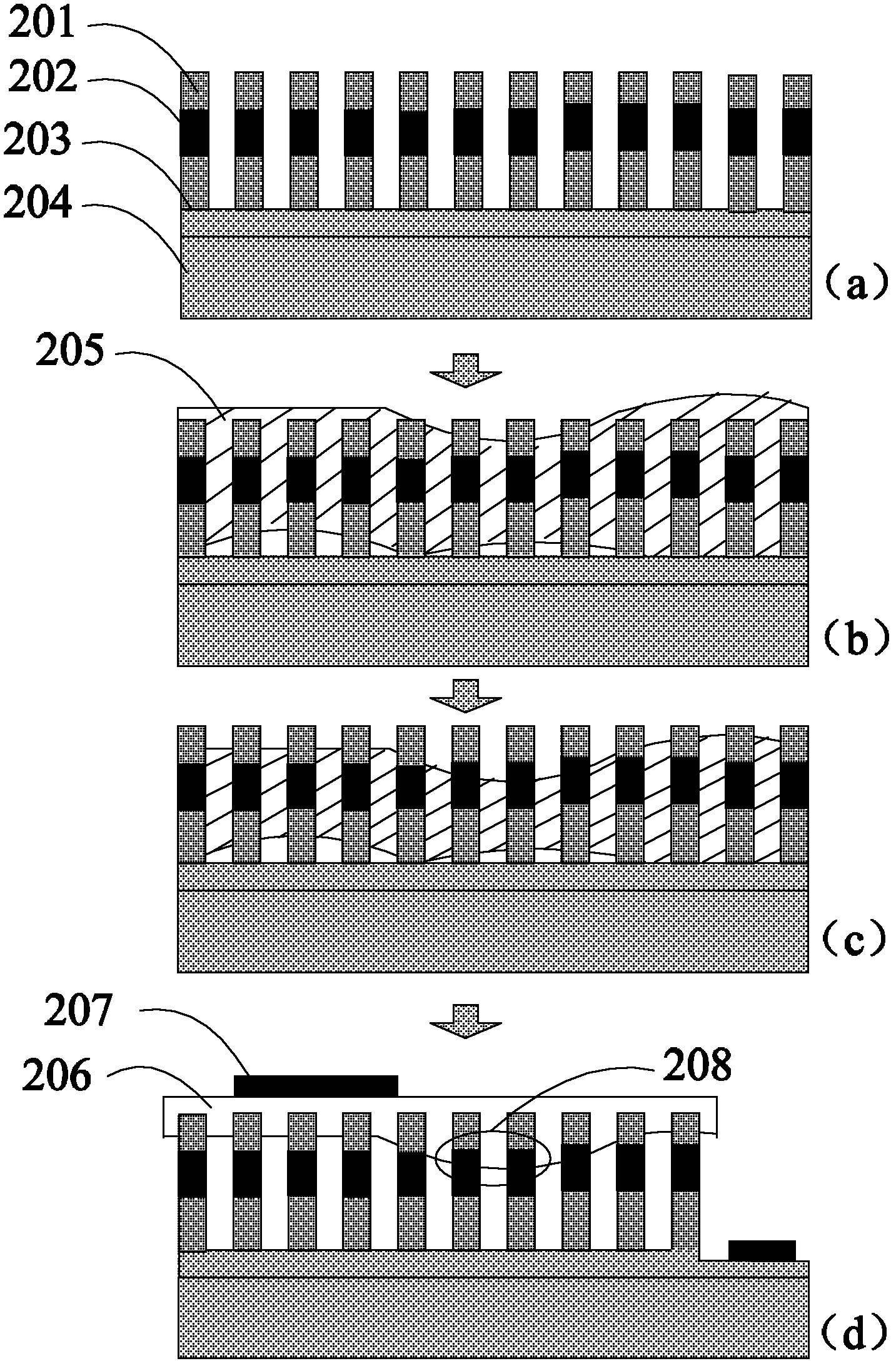

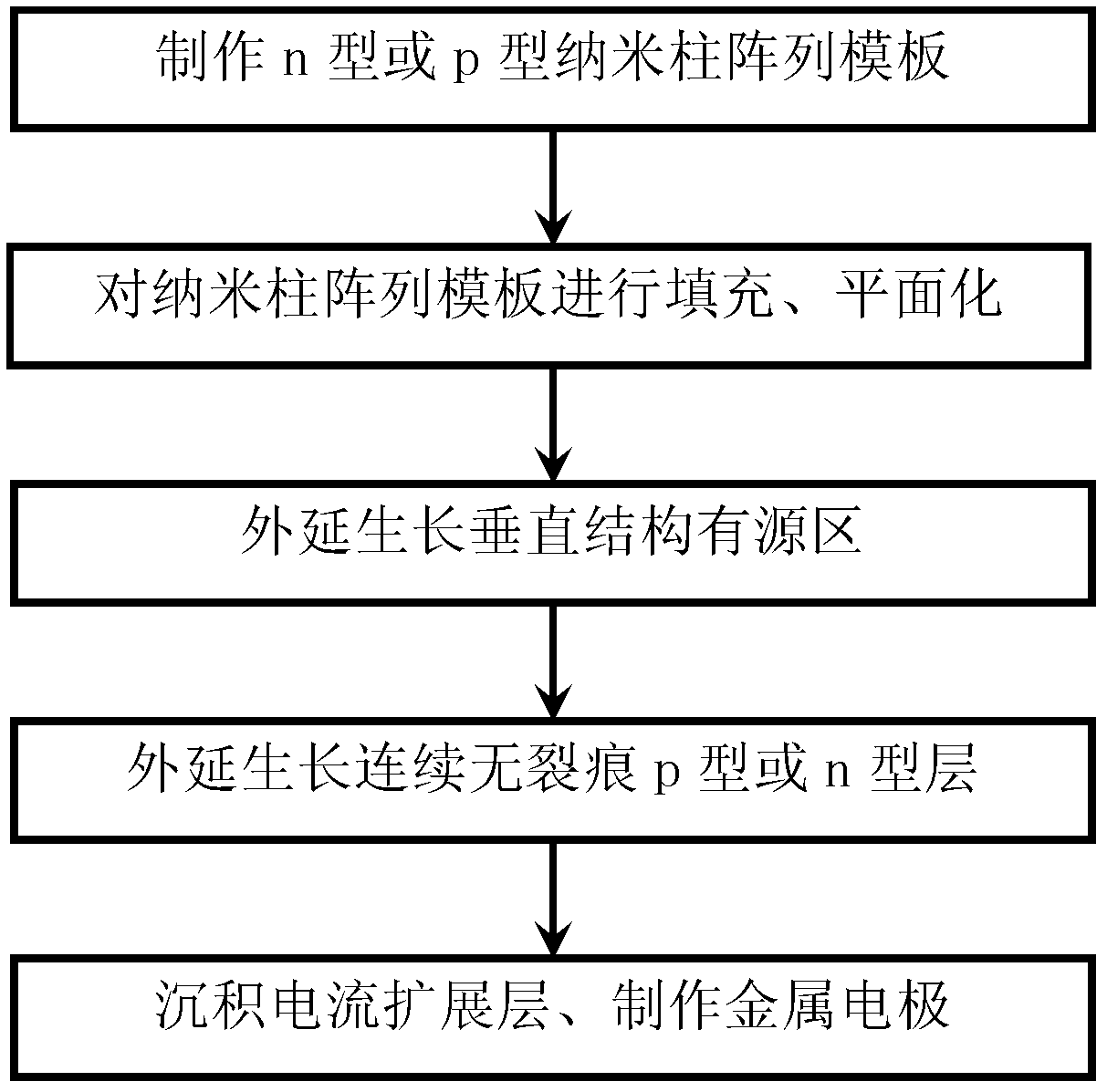

[0035] The preparation method of the photoelectric device based on the nano-column array of the present invention is illustrated by taking the nano-column array InGaN / GaN p-i-n double heterojunction solar cell structure prepared on the sapphire substrate as an example, wherein the intrinsic InGaN absorbing layer is equivalent to other photoelectric devices. source area, see Figure 3-5 , its manufacturing process includes the following main steps:

[0036] Step 1: Make a microstructure mask layer on the top layer of n-type GaN, and etch to form a nanopillar array:

[0037] Firstly, the sample is cleaned, and the substrate is placed in a plasma-enhanced chemical vapor deposition (PECVD) vacuum chamber, the temperature of the substrate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com