An internal reaming tool based on continuous automatic chip removal for blind deep holes

A technology for reaming tools and deep holes, which is applied to lathe tools, boring/drilling, drilling/drilling equipment, etc. It can solve the problems of small vibration, achieve complete functions, uniform chip breaking, and reduce Effect of Surface Roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

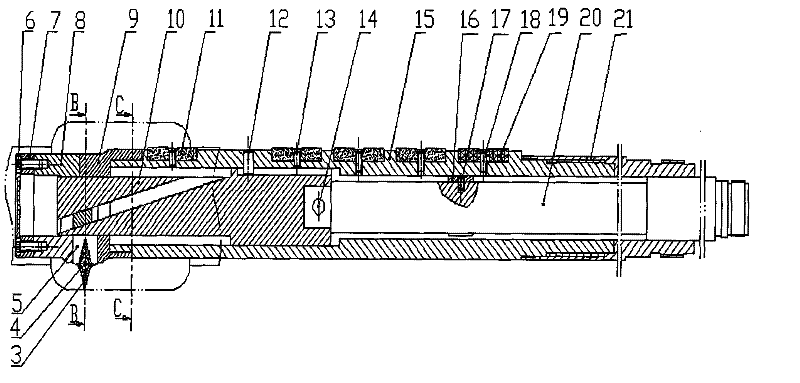

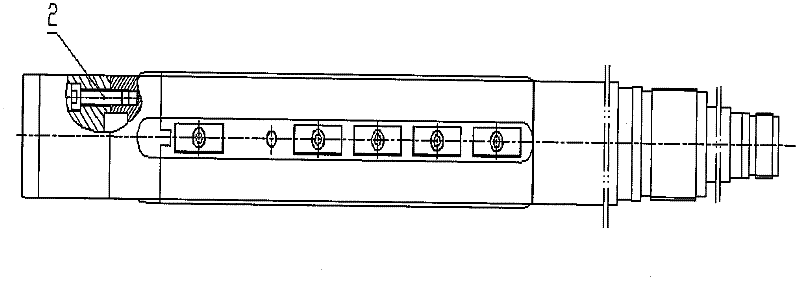

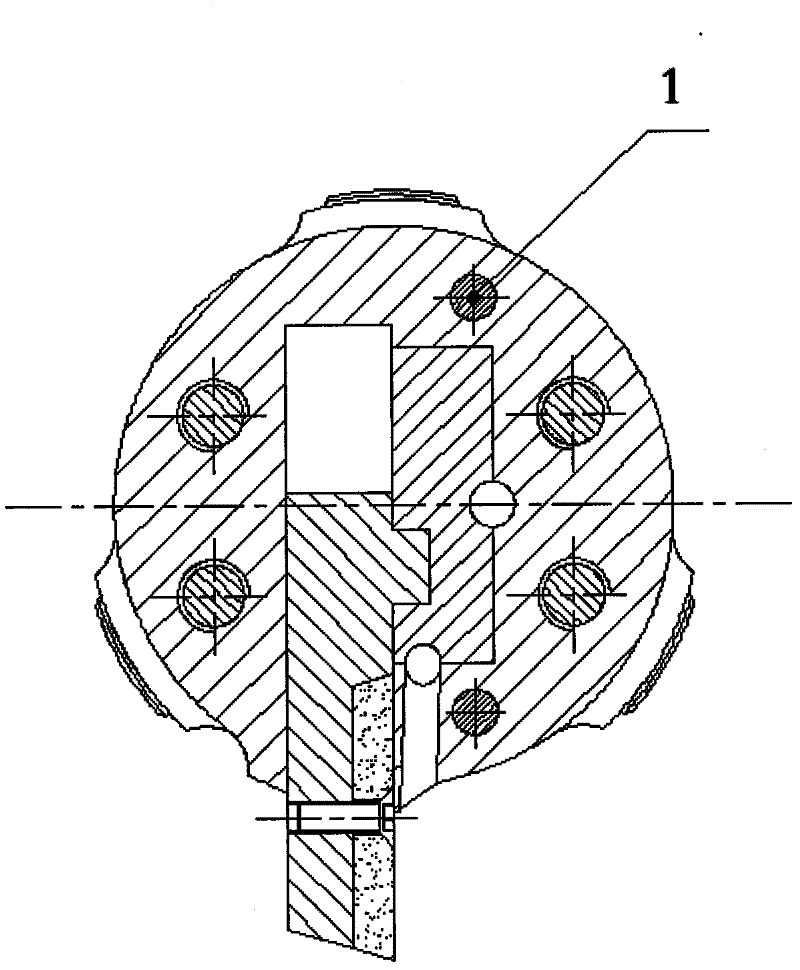

[0021] As shown in the drawings, the present invention of the present invention is characterized in that: the pull rod support sleeve 16 is connected with the push-pull rod 20 through the countersunk head screw 17, and the push-pull rod 20 is connected with the guide rail 10 through the conical pin 14 to form a push-pull mechanism; The pin 12 is connected with the boring tool body 15 through interference fit, and plays the role of preventing the guide rail 10 from rotating and limiting during the sliding process; the diamond-shaped coating machine clip blade 3 is fixed on the small boring tool body 5 with a specific countersunk head screw 4 Composition of the mobile tool rest mechanism; under the left and right movement of the push-pull rod 20, the small boring tool body 5 is driven to slide in the chute of the guide rail 10 to realize the radial and free telescopic movement of the entire mobile tool rest mechanism; the end cover 7 uses two countersunk screws 6 It is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com