A kind of preparation method of mcm-48 mesoporous molecular sieve

A technology of MCM-48 and mesoporous molecular sieve, which is applied in the field of preparation of high thermal stability silicon-based mesoporous molecular sieve MCM-48, can solve the problems of harsh synthesis conditions, complicated separation, narrow synthesis phase area, etc. The effect of reducing environmental pollution and simplifying operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] First, 2.104 g of NaOH was added to a beaker containing 68 ml of deionized water, followed by 17.42 g of silica sol (SiO 2 =30%, Ludox-AM30), stirred at 60°C for 1 hour to obtain solution A; 2.705g of cetyltrimethyl-p-toluenesulfonate (CTATos) was added to a beaker containing 80ml of deionized water , stirred at 60°C for 1 hour until the solution became clear, and solution B was obtained; solution A was added dropwise to solution B, stirred at 60°C for 2 hours, and a white precipitate was obtained. The molar composition of the mixture was SiO 2 / CTATos / NaOH / H 2 O = 1:0.068:0.60:102; after the mixture is cooled to room temperature, it is transferred to a reactor for crystallization at 130°C for 20 hours, the product obtained is suction filtered, washed, and dried, and the obtained raw powder is roasted at 550°C for 6 hours. The MCM-48 mesoporous molecular sieve was obtained with a yield of 50%.

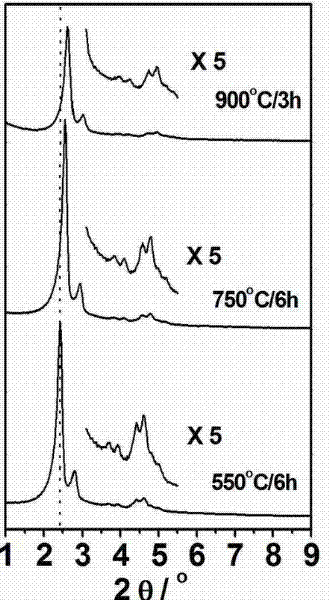

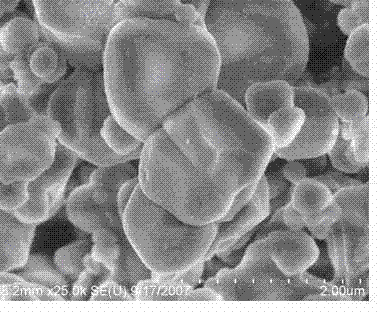

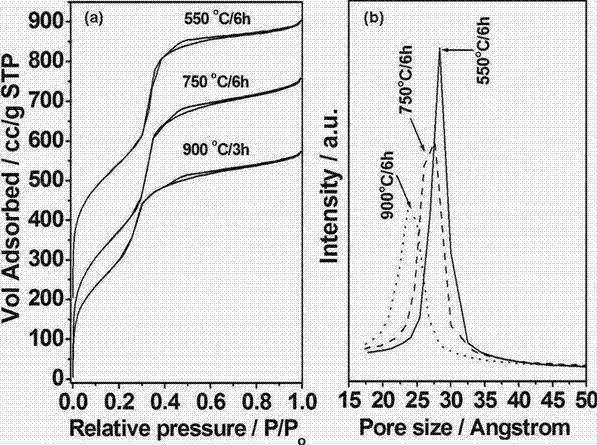

[0017] The thermal stability test of the obtained MCM-48 mesoporous molec...

Embodiment 2

[0019] Silica sol (Zhejiang Yuda Chemical Reagent Company, sodium-free 30% silica sol) was used as a silicon source to prepare high-quality MCM-48 mesoporous molecular sieves:

[0020] Except that Zhejiang Yuda sodium-free silica sol was used instead of Ludox-AM30 in Example 1, other preparation conditions were the same as in Example 1.

Embodiment 3

[0022] Potassium hydroxide is used as an alkali source to prepare high-quality MCM-48 mesoporous molecular sieves:

[0023] Except replacing the sodium hydroxide in embodiment 1 with potassium hydroxide, other preparation conditions are all identical with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com