A kind of reactor and method for removing nitrate in water

A reactor, nitrate technology, applied in chemical instruments and methods, water pollutants, water/sludge/sewage treatment, etc., to achieve the effects of high microbial adhesion, high hydrogen production and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

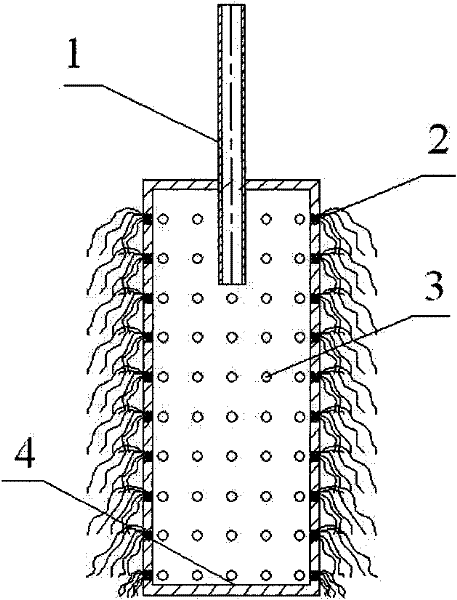

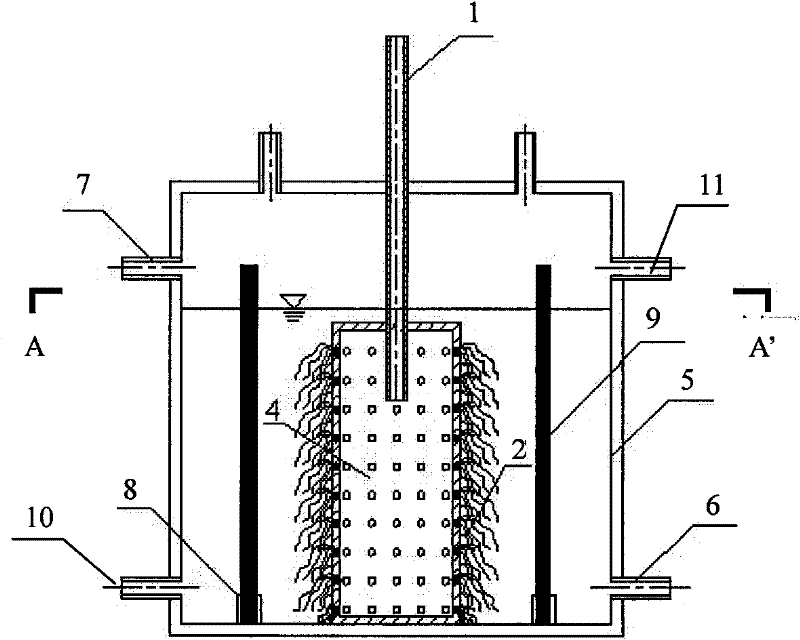

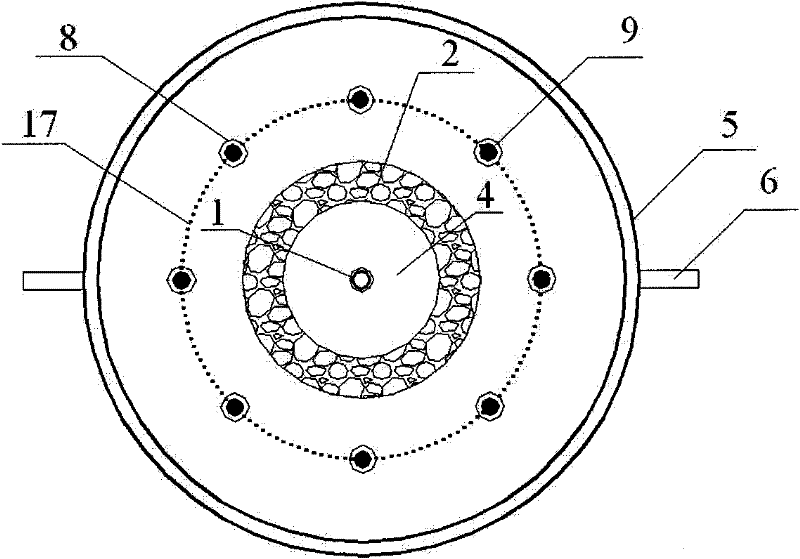

[0073] The biological carrier support cylinder is a cylinder made of plexiglass, with a height of 200mm, a diameter of 80mm, and a volume of 1.0L. Small holes with a diameter of 5 mm are evenly punched on the wall of the cylinder, and the distance between the holes is 18 mm along the circumferential direction and 20 mm along the normal direction, a total of 108 small holes. The small hole is filled with cotton thread, and a 1mm thick cotton thread (80% cotton, 20% acrylic) is hung on the cylinder wall as a soft biofilm carrier. The length of the external cotton thread is about 100mm, and the total effective volume is 3603cm 3, the wall of the cylinder is completely covered by cotton thread; 5m stainless steel wire (cathode) is fixed on the biological carrier support cylinder, and evenly interspersed and embedded in the soft carrier, and the end is connected with the cathode of the power supply; 8 carbon rods (anode) Evenly arranged in a circle, distributed around the soft carr...

Embodiment 2

[0076] The preparation of the biofilm module and the method for removing nitrate in water are as example 1, the nitrate concentration in the influent is 50mg / L, the C / N is 1.0, the pH is 7.6, the HRT is 8 hours, and when the current I is 10mA, the nitrate concentration in the effluent is 0.02mg / L; the concentration of nitrite is less than 0.01mg / L, all of which meet the national drinking water standards.

Embodiment 3

[0078] The preparation of the biofilm module and the method for removing nitrate in water are as example 1. The nitrate concentration in the influent is maintained at 50 mg / L, the C / N is 0.5, the pH is 7.1, the HRT is 8 hours, and when the current I is 100mA, the nitrate in the effluent Concentration 0.6mg / L, in line with national drinking water standards.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com