Method for producing n-butyl acetate through microwave pipeline

A n-butyl acetate, pipeline technology, applied in the direction of chemical instruments and methods, preparation of carboxylic acid esters, preparation of organic compounds, etc., can solve the problems of reduced yield, no production practicability, complexity, etc., and achieve increased reaction speed , Simplified production operation, fast esterification reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

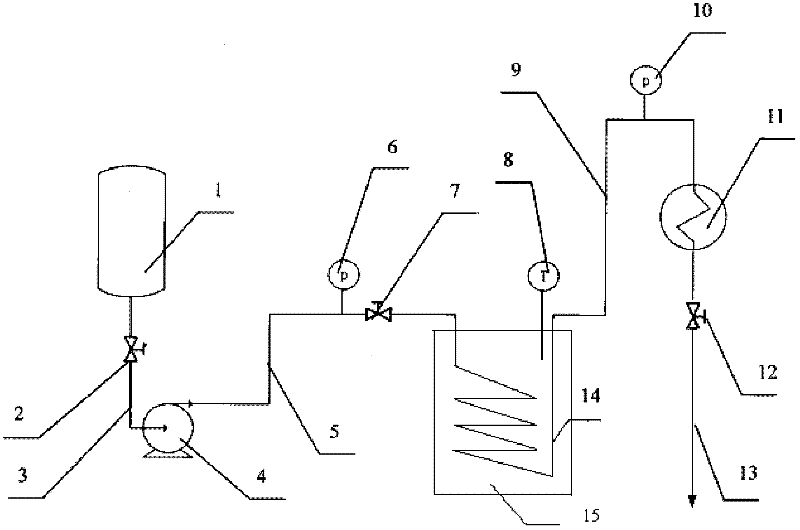

[0014] Embodiment 1, figure 1 A pipeline reactor is provided, comprising a raw material tank 1, a metering pump 4, a pipeline reactor 14 and a condenser 11; the outlet of the raw material tank 1 is connected to the metering pump 4 through a pipeline I 3, and the metering pump 4 passes through the pipeline II 5 is connected to the inlet of the tube reactor 14, the outlet of the tube reactor 14 is connected to the inlet of the condenser 11 through the pipeline III9, and the outlet of the condenser 11 is connected to the pipeline IV13. A cut-off valve I 2 is arranged on the pipeline I 3, a pressure gauge I 6 and a shut-off valve II 7 are respectively arranged on the pipeline II 5 according to the flow direction, a thermometer 8 is arranged on the pipeline reactor 14, and a thermometer 8 is arranged on the pipeline III9. A pressure gauge II 10 is provided, and a stop valve III 12 is provided in the pipeline IV 13 . The entire tube reactor 14 is placed in a microwave generator 15 ...

Embodiment 2

[0017] Embodiment 2, a kind of method of pipeline production n-butyl acetate, adopt the pipeline reactor described in embodiment 1, carry out following steps successively:

[0018] 1), raw material preparation:

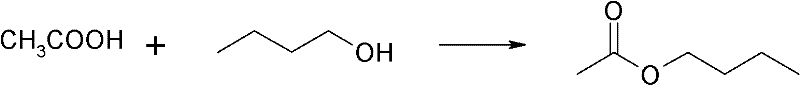

[0019] Add 74 g (1.0 mol) of n-butanol and 60 g (1.0 mol) of acetic acid into the raw material tank 1, and mix thoroughly to obtain a mixed solution.

[0020] 2), esterification reaction:

[0021] Use the metering pump 4 to pump the above-mentioned mixed solution into the pipeline reactor 14, the reaction temperature is 60°C, the reaction pressure is normal pressure, and the power of the microwave generator is adjusted to 400w; the flow rate of the metering pump 4 is controlled to make the reactant (i.e. the mixed solution ) is 1000ml / h at the flow rate of pipeline reactor, and promptly reaction time is about 6mins, obtains the crude product liquid containing n-butyl acetate.

[0022] 3), post-processing:

[0023] The above-mentioned crude product liquid containing...

Embodiment 3

[0024] Embodiment 3, a kind of method of pipeline production n-butyl acetate, adopt the pipeline reactor described in embodiment 1, carry out following steps successively:

[0025] 1), raw material preparation:

[0026] Add 74 g (1.0 mol) of n-butanol and 90 g (1.5 mol) of acetic acid into the raw material tank 1, and mix thoroughly to obtain a mixed solution.

[0027] 2), esterification reaction:

[0028] Use the metering pump 4 to inject the above-mentioned mixed solution into the pipeline reactor 14, the reaction temperature is 80°C, the reaction pressure is normal pressure, and the power of the microwave generator is adjusted to 600w; the flow rate of the metering pump 4 is controlled to make the reactant (i.e. the mixed solution ) is 500ml / h at the flow rate of pipeline reactor, promptly reaction time is about 12mins, obtains the crude product liquid containing n-butyl acetate.

[0029] 3), post-processing:

[0030] The above-mentioned crude liquid containing n-butyl a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com