A kind of immobilized lipase catalyzes the method for preparing biodiesel from pistachio oil

A technology of immobilizing lipase and pistachio oil, which is applied in the fields of immobilized on/in organic carriers, biofuels, chemical industry, etc., can solve problems affecting mass transfer, hindering cross-linking reactions, and blocking enzymes from entering, etc. To achieve the effect of improving the stability of use, low price and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

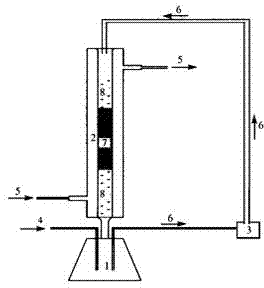

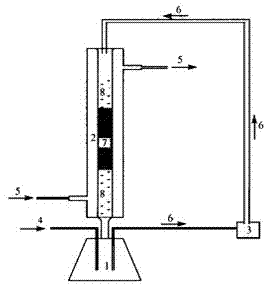

Image

Examples

Embodiment 1

[0035] The present invention selects natural fiber---ramie as carrier, and three steps of activation of ramie, porcine pancreas lipase liquid preparation and cross-linking are carried out:

[0036](1) Activation of ramie: cut some ramie, boil with 0.5mol / L KOH for 0.5 hour to remove impurities on the surface of ramie, then oxidize with 0.1 mol / L NaI04 solution, take it out after 6 hours and wash it with deionized water , add glycerol to the surface of ramie and let it stand for 40 min to remove unreacted NaIO4, and wash it with deionized water for later use.

[0037] (2) Preparation of enzyme solution: Dissolve a certain amount of porcine pancreatic lipase dry powder in 50mL of phosphate buffer (0.025mol / L, pH 7.5), stir evenly at 4°C, and centrifuge at 10,000r / min for 10 min , and then take the supernatant and store it in the refrigerator for later use.

[0038] (3) Cross-linking: put the activated ramie in step (1) in an Erlenmeyer flask and cross-link with the enzyme s...

Embodiment 2

[0040] The present invention selects natural fiber---ramie as carrier, and three steps of activation of ramie, porcine pancreas lipase liquid preparation and cross-linking are carried out:

[0041] (1) Activation of ramie: cut some ramie, boil with 0.8mol / L KOH for 0.6 hours to remove impurities on the surface of ramie, then oxidize with 0.3 mol / L NaI04 solution, take it out after 8 hours and wash it with deionized water , add glycerol to the surface of ramie and let it stand for 50 min to remove unreacted NaIO4, and wash it with deionized water for later use.

[0042] (2) Preparation of enzyme solution: Dissolve a certain amount of porcine pancreatic lipase dry powder in 50mL of phosphate buffer (0.0.500mol / L, pH 7.5), stir evenly at 4°C, and centrifuge at 10,000r / min for 10 min, and then take the supernatant and store it in the refrigerator for later use.

[0043] (3) Cross-linking: Put the activated ramie in step (1) in a conical flask and cross-link with the enzyme so...

Embodiment 3

[0045] The present invention selects natural fiber---ramie as carrier, and three steps of activation of ramie, porcine pancreas lipase liquid preparation and cross-linking are carried out:

[0046] (1) Activation of ramie: Cut some ramie, boil with 1.0mol / L KOH for 1.0 hour to remove impurities on the surface of ramie, then oxidize with 0.6 mol / L NaI04 solution, take it out after 12 hours and wash it with deionized water, Add glycerol and let it stand for 60 min on the surface of ramie to remove unreacted NaIO4, and wash it with deionized water for later use.

[0047] (2) Preparation of enzyme solution: Dissolve a certain amount of porcine pancreatic lipase dry powder in 50mL of phosphate buffer solution (0.025-0.500mol / L, pH 7.5), stir evenly at a low temperature of 4°C, and dissolve at a speed of 10000r / min Centrifuge for 10 min, then take the supernatant and store it in the refrigerator for later use.

[0048] (3) Cross-linking: put the activated ramie in step (1) in a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com