A kind of preparation method of bagasse xylan acetate

A technology of sugar acetate and polyacetate, applied in the field of preparing bagasse xylan acetate, which can solve the problem of low substitution degree of products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

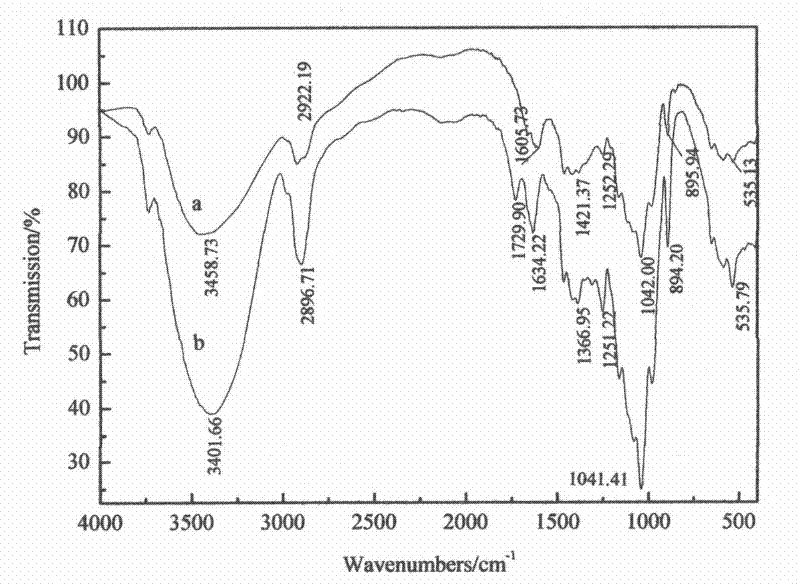

Method used

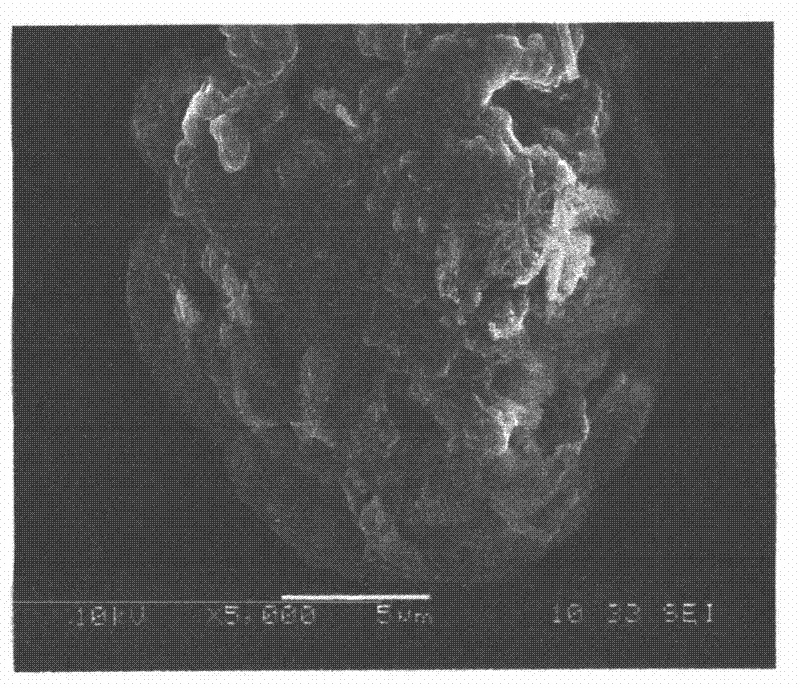

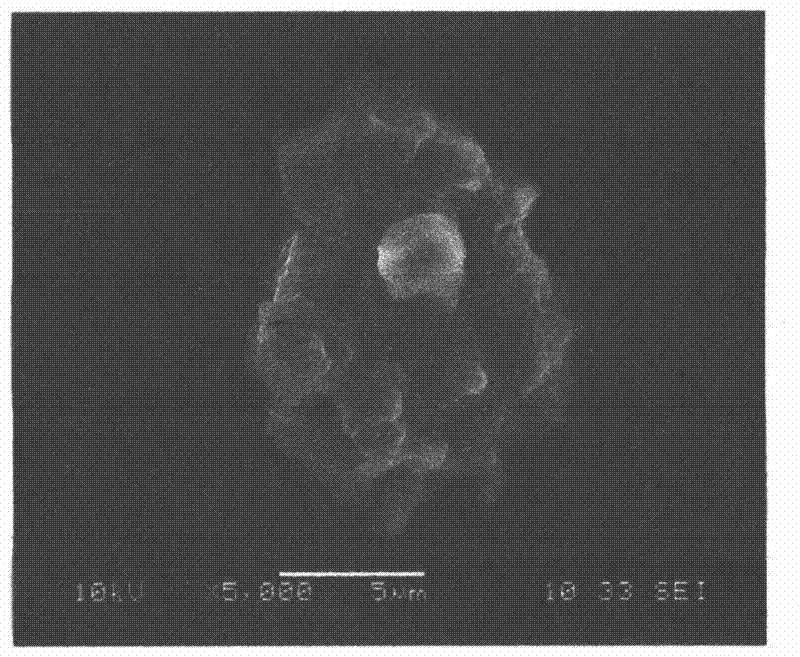

Image

Examples

Embodiment 1

[0032] (1) drying the bagasse xylan in a vacuum oven at 50° C. for 24 hours;

[0033] (2) Get dried xylan 15g and absolute ethanol 30mL and add in the 250mL four-necked flask that is equipped with reflux condenser, stirring device, mix and stir 60min at room temperature, solvent and bagasse xylan are fully mixed, and It can activate part of the hydroxyl groups in bagasse xylan molecules.

[0034] (3) Adjust the temperature to 60°C, slowly add the mixed solution of 6 g of analytically pure acetic anhydride and 0.15 g of analytically pure sulfamic acid into the four-necked flask with a constant pressure dropping funnel, and keep the temperature for 5 h.

[0035] (4) Pour the reaction solution into a beaker, let it stand for cooling for 30 minutes, repeatedly wash and suction filter with industrial ethanol with a mass concentration of 85%, put the filter cake in a glass dish, and dry it in a vacuum oven at 60°C until constant Weight is the product.

[0036] (5) The degree of su...

Embodiment 2

[0038] (1) drying the bagasse xylan in a vacuum oven at 50° C. for 24 hours;

[0039] (2) Get dried xylan 20g and dehydrated ethanol 50mL and add in the 250mL four-neck flask that is equipped with reflux condenser, stirring device, mix and stir 60min at room temperature, solvent and bagasse xylan are fully mixed, and It can activate part of the hydroxyl groups in bagasse xylan molecules.

[0040] (3) Adjust the temperature to 70°C, slowly add the mixed solution of 12g of analytically pure acetic anhydride and 0.4g of analytically pure sulfamic acid into the four-necked flask with a constant pressure dropping funnel, and keep the temperature for 6h.

[0041] (4) Pour the reaction solution into a beaker, let it stand for cooling for 30min, repeatedly wash and filter with industrial ethanol (mass concentration 85%), put the filter cake in a glass dish, and dry it in a vacuum oven at 60°C until Constant weight is the product.

[0042] (5) The degree of substitution of the produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com