Method for preparing iron-nickel or iron-nickel-chromium alloy foil and electrolyte used in same

A chromium alloy and trivalent chromium technology, applied in the electrolysis process, electroforming, etc., can solve the problems of difficulty in obtaining complete foil, poor electrolyte stability, high iron content in alloy foil, etc., and achieve easy maintenance, stable electrolyte, iron and The effect of high chromium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

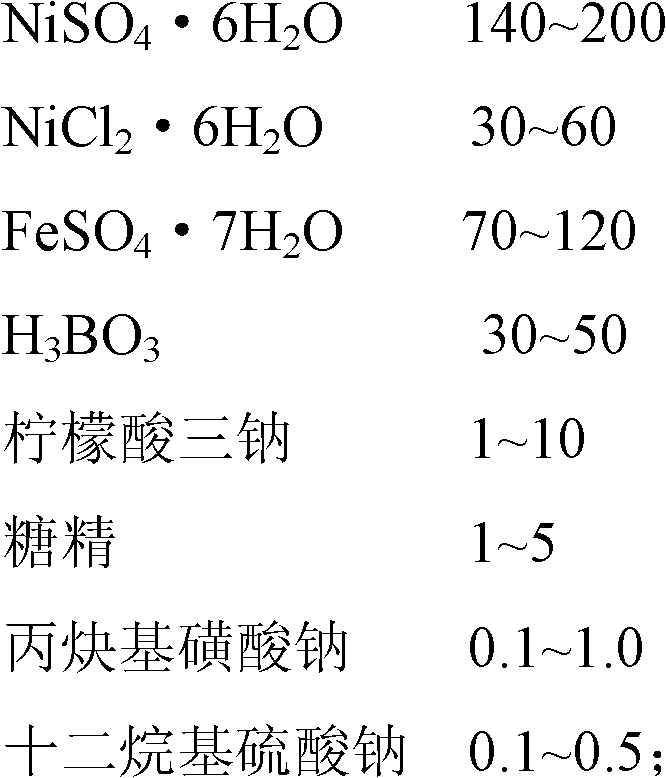

[0025] Using the process conditions shown in Table 1 to produce a thickness that meets the above requirements is 20um and a width of 1.5m. 63.5 Ni 36.5 Alloy foil, thermal expansion coefficient 2.0×10 -6 / ℃, the magnetic saturation intensity is 1.4T, and the magnetic permeability is 3.0×10 4 , the resistivity is 50μΩ.cm.

[0026] Table 1 Electrolyte composition and process conditions of electrodeposited iron-nickel alloy foil

[0027] project

Embodiment 2

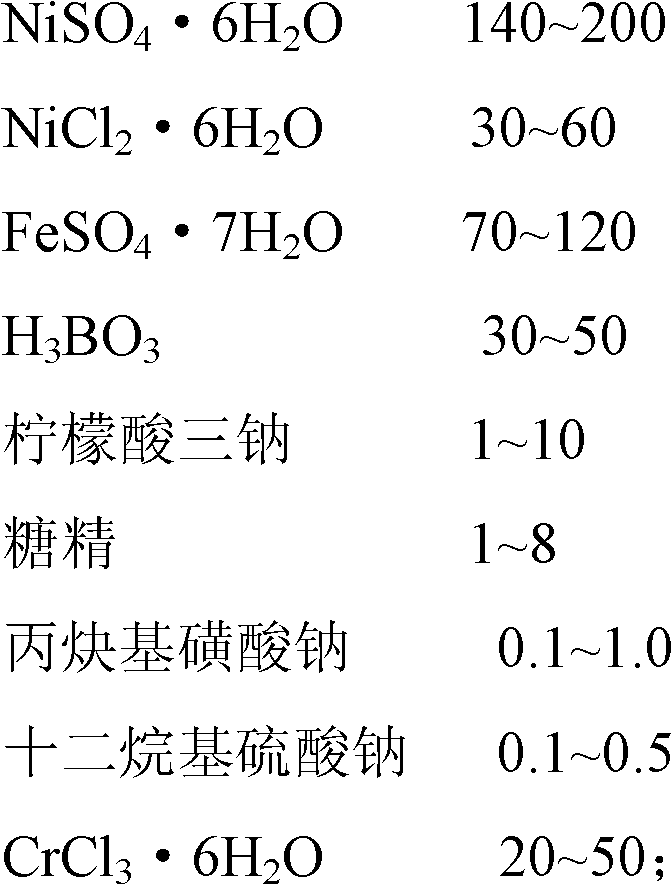

[0029] Using the process conditions shown in Table 2 to produce a thickness that meets the above requirements is 20um and a width of 1.5m. 61.2 Ni 33.7 Cr 5.1 The ternary alloy foil has a tensile strength of 800.0Mpa, an elongation of 6.67%, a magnetic saturation strength of 1.5T, and a magnetic permeability of 3.0×10 4 , the resistivity is 70μΩ.cm.

[0030] Table 2 Electrolyte composition and process conditions of electrodeposited iron-nickel-chromium ternary alloy foil

[0031] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com